Airtech and AES Collaborate to Grow Large Format Additive Manufacturing Applications

As part of the partnership, Airtech will provide comprehensive support to AES in additive manufacturing business opportunities and technical areas, while AES commits to exclusive use of Airtech products in its LFAM projects to ensure high quality and performance standards.

Share

Read Next

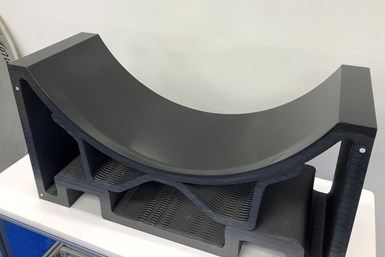

Airtech validated its Dahltram I-350CF high-temperature polymer for large-format toolmaking applications. Source: Airtech Advanced Materials Group

Airtech Advanced Materials Group, an industry provider of specialty formulated additive manufacturing (AM) materials, and Additive Engineering Solutions (AES), a provider with the industry’s largest installed capacity of large-format additive manufacturing (LFAM), have entered into an exclusive supply agreement.

As part of this agreement, Airtech will provide comprehensive support to AES in AM business opportunities and technical areas. In return, AES commits to exclusive use of Airtech products in its LFAM projects to ensure high quality and performance standards.

The collaboration will extend beyond product supply, encompassing joint efforts in design practices, material characterization, tooling-to-part interaction, material processing, new material development and market penetration strategies.

“This is a logical agreement between two market leaders in the LFAM space and we are thrilled to further our existing relationship with Airtech,” says Austin Schmidt, AES president and co-founder.

Andy Bridge, AES director of business development adds, "I have been impressed with the level of material testing, especially tool-part interaction evaluation that Airtech focuses on.”

The exclusive partnership between Airtech Advanced Materials Group and Additive Engineering Solutions holds significant promise for the LFAM sector. By pooling their expertise and resources, both companies aim to deliver enhanced product quality, streamlined processes, and innovative solutions. With a focus on driving real-world results and customer satisfaction, this collaboration signifies a practical step forward in addressing industry challenges, new market penetration and meeting evolving customer needs.

Airtech says it is committed to supporting AES and its clients. “Airtech is excited to expand their relationship with one of the first commercial adopters of LFAM in North America,” says Gregory Haye, Airtech director of additive manufacturing. “AES is dedicated to this technology and delivering meaningful problem-solving solutions to their customers. We look forward to supporting AES customer project success by providing our industry-leading material solutions and technical support capabilities.”

AES says it is the first manufacturer to offer contract LFAM services globally. Established in 2016, AES has four LFAM printers that are supported by four large CNC mills and a dedicated team of experienced engineers. The company specializes in design and fabrication of 3D printed tooling for composites, end-use items, full-scale engineering mockups, marketing displays and assembly verification articles. Key markets supplied include defense, general aviation, marine and space.

Airtech Advanced Materials Group says it is the largest privately-owned manufacturer of vacuum bagging and composite tooling materials for prepreg/autoclave, resin infusion and wet lay-up processes up to 799°F (426°C).

The company Airtech serves a diverse range of sectors, including aerospace, wind energy, solar, marine, automotive and general composites. The company’s latest advancements include LFAM, advanced Dahltram tooling and multipurpose thermoplastic resins.

Related Content

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

-

“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

-

Part Removal Efficiency In a 600 mm Plus World

Clay Olson of EDM Performance Accessories discusses the difficulties and opportunities in cutting off parts from the build plates of large AM systems. Molybdenum wire EDM offers an effective solution to the challenge of large-part cutoff.