AddUp, Dassault Systèmes Collaborate on Aerospace Digital Continuity Project

The companies are collaborating on the Aeroprint project, which aims to establish a certified additive manufacturing pilot line for aeronautics.

AddUp has joined the Dassault Systèmes’ 3DExperience platform ecosystem as part of the Aeroprint project, which aims to establish a certified additive manufacturing (AM) pilot line for aeronautics. AddUp is a global metal AM OEM offering a series of industrial 3D metal printers utilizing both laser powder bed fusion (LPBF) and directed energy deposition (DED) technologies.

With the 3DExperience platform, Dassault Systèmes offers a dedicated set of applications for AM — from new material characterization, adapted design, build job preparation and simulation to shopfloor scheduling and execution monitoring. By working on a single platform, users can ensure digital continuity across the entire life cycle of parts production.

At the heart of this collaboration is Aeroprint, an R&D project driven by Dassault Aviation which is located in the French region of Auvergne-Rhône-Alpes. One of the expected deliverables is the establishment of a certified AM pilot line for aeronautics, an industry particularly sensitive to the benefits of this technology. Dedicated to accelerating the adoption of AM by the aeronautics industry, an industrial platform at the Argonay site is being set up. With such ambitions, the company says only perfectly integrated digital solutions can be considered. This is where AddUp and Dassault Systèmes’ work takes on its full meaning.

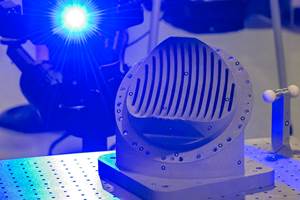

AddUp created a virtual twin of its FormUp 350 by using AddUp NTwin, a solution dedicated to FormUp interoperability, that enables 3DExperience platform users to seamlessly produce a job file, retrieve additional build information and run simulations. This Virtual Twin is available to 3DExperience platform users in the AddUp community hosted by Dassault Systèmes.

The company says interoperability is a strong expectation for industrial manufacturers that plan on taking AM to a daily large-scale level. It connects not only a single machine to a global industrial environment but also offers digital continuity and simplification for upstream production processes. In other words, it’s a key to efficiency, of which the Aeroprint project will be the first beneficiary.

The virtual twin of the FormUp 350 machine in the 3DExperience platform enables the production file to be created interactively. Thanks to this virtual twin, Dassault Aviation is able to ensure digital continuity from design to the manufacturing of the part in the 3DExperience platform.

Leaving the standard asynchronous workflow and its CAD-to-STL conversion, this synergy provides better traceability and flexibility over time. Users can access powerful 3DExperience platform features and applications, while creating strategies and generating trajectories within seconds using the AddUp Trajectory Generator. For perfect process mastery, trajectories are displayed directly in the Delmia application, before being sent to Simulia applications for process simulation.

The solution is available from the AddUp community, where they can also find information and use cases as well as ask AddUp and Dassault Systèmes members questions.

- Learn about AddUp adding Constellium’s Aheadd CP1 aluminum alloy to its material portfolio. The Aheadd CP1 aluminum alloy was developed by Constellium for the needs of additive manufacturing by laser powder bed fusion specifically for high-performance and lightweight applications.

- Read more about how AddUp’s FormUp 350 Evolution printer prints parts up to 1 meter tall. The FormUp 350 Evolution machine is designed to produce large metal parts with a high level of complexity and precision, which is an ability in high demand in the aeronautics, space, defense and energy sectors.

Related Content

Additive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreWhy AM Leads to Internal Production for Collins Aerospace (Includes Video)

A new Charlotte-area center will provide additive manufacturing expertise and production capacity for Collins business units based across the country, allowing the company to guard proprietary design and process details that are often part of AM.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More