News

3D Control Systems, HP Collaborate on Multi Jet Fusion Connectivity

The integration of HP 3D API enables 3D Control Systems’ customers using HP Jet Fusion systems to streamline workflow, optimize job efficiency and analyze production efficiency with access to critical data.

Read MoreDesktop Metal Launches Desktop Health for Patient-Specific Solutions

Health care business leverages Desktop Metal’s portfolio of AM solutions for current and future applications spanning dentistry, orthodontics, dermatology, orthopedics, cardiology, plastic surgery, and printed regenerative tissues and grafts.

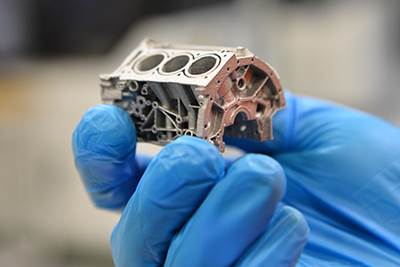

Read MoreExOne, Ford Motor Co. Develop Aluminum Binding Jetting Process

This aluminum engine block model, 3D printed in 6061, demonstrates the high resolution and geometric control that can be produced in a new binder jet 3D printing and sintering process developed by Ford and ExOne.

Read More3D Printing Tech Acquires Voodoo Manufacturing

The acquisition is a step toward operating one of the largest fused deposition modeling print farms in the U.S.

Read MoreNavy Awards $1.5M Contract for Meld Technology for Metal Printing, Repair

Program will further the Navy’s ability to support critical operations by delivering instructions and training for repair and printing of naval metal parts on site at the shipyard.

Read MoreDesktop Metal, Uniformity Labs Develop Fully Dense, Sinterable Aluminum

Uniformity 6061 aluminum will be available exclusively to Desktop Metal customers as part of its ongoing partnership with Uniformity Labs.

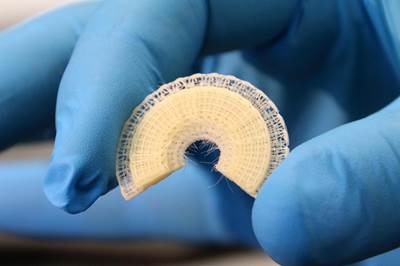

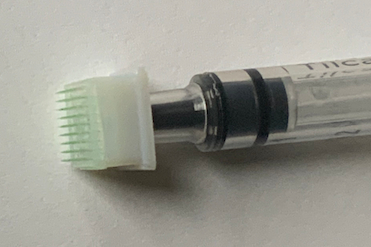

Read MoreResearchers Developing Scalable Manufacturing for Novel Vaccine Delivery

Hybrid-MNA technology may significantly help reduce vaccine shortages.

Read MoreThermwood Technology Ensures Complete Fusion for Large-Scale 3D Printing

LSAM also makes print temperature control completely automatic.

Read MoreStratasys Direct, Xometry Partner to Deliver 3D Printed Parts on Demand

Stratasys Direct Manufacturing is providing several new high-performance nylon material options to customers of Xometry’s global custom manufacturing marketplace.

Read MoreSintavia Acquires Three More GE Additive Arcam A2X EB Printers

Company using them to manufacture high-precision structural titanium components for the aerospace and defense industry.

Read More