The Case for Tackling the Toughest Material First

The increasing speed and power of high-end processors and data centers has created a market for advanced thermal management solutions. A Silicon Valley startup called Holo is dedicating its first line of products toward this market, starting with 3D-printed copper heat exchangers.

Share

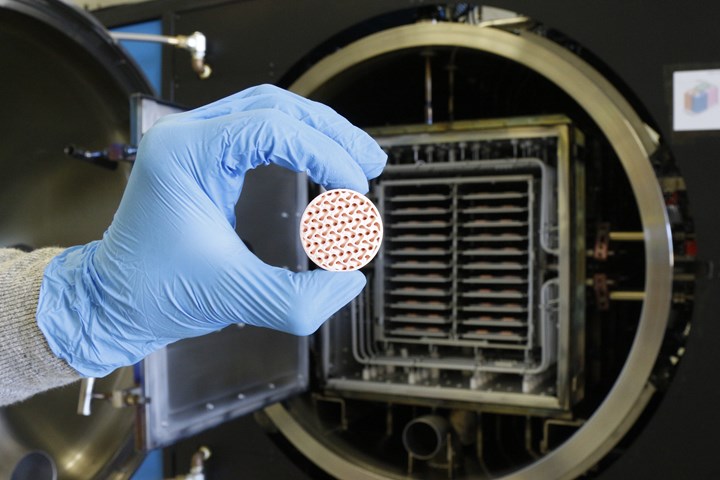

A Holo employee holds a sintered copper part from a MIM furnace. This the last step the company uses to produce complex copper parts such as heat exchangers and liquid-cooled coldplates for thermal management applications. Photo Credit: Holo

Do the production applications of metal additive manufacturing (AM) need to favor the kinds of companies that can afford million-dollar machines to make parts for the aerospace and medical industries? Arian Aghababaie doesn't think so. This question inspired him to start a new company, dedicated to digital manufacturing at scale for intricate metal parts in high-performance applications, including relatively low-cost applications.

That company is Holo, a Silicon-Valley-based startup and spinout of Autodesk, where Aghababaie worked for several years developing and launching the well-established software company’s first hardware product: an open-source stereolithography 3D printer called Ember.

In many ways, Holo exists as an evolution of Aghababaie’s experience producing Ember, with a few key differences. Both Ember and Holo’s 3D printers are based around digital light processing (DLP) technologies that create high-resolution parts for low-cost prototyping and production. But Holo takes that same underlying approach and applies it to metals, necessarily adding a backend process that debinds green-state polymerized parts and sinters them in a metal injection molding (MIM) furnace.

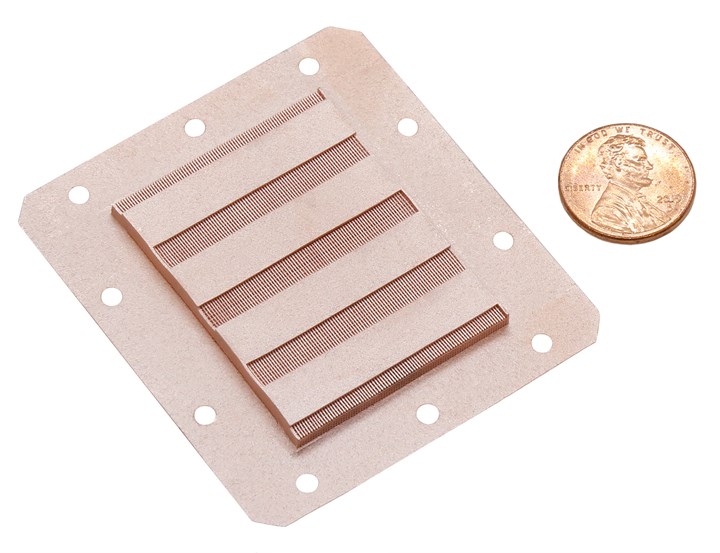

A 3D-printed copper coldplate manufactured by Holo. The company uses digital light processing along with a backend process that debinds green-state polymerized parts and sinters them in a metal injection molding furnace. Photo Credit: Holo

Another key difference: Holo is a parts provider. The company, at least for the near future, doesn’t plan to sell its Holo-branded printers. Instead, Holo’s business model centers on targeting end markets that stand to gain the most from additive manufacturing but have been locked out due to high costs.

Aghababaie points to the computer industry as one of those markets — specifically companies that develop cooling solutions for data centers, high-end CPUs and electric vehicles.

These applications — complex heat exchangers and liquid cooling devices — require the kind of high fidelity, complex geometries for which DLP printing is well suited, Aghababaie says. And this brings us to what he calls Holo’s secret sauce: a proprietary feedstock recipe that contains powdered metal and photopolymer binders that, together, create a high-tech slurry the company uses to print parts.

A Matter of Flow

Among the “huge swaths of industries” that Aghababaie says have had limited access to additive manufacturing are the producers of semiconductors for data centers, CPU cooling and electric vehicles. The microchips used for large data centers in particular can fetch from several hundred to several thousand dollars each. All of these applications have undergone massive improvements that have increased performance exponentially in recent years — think Moore’s Law — a feat that also requires increases in the raw power needed to enable faster and faster processing speeds.

Along with higher power comes higher heat, and a general push toward liquid cooling solutions that replace traditional air-cooled heat sinks and cooling plates. Holo’s initial focus on CPU cooling devices meant that the company needed to 3D print copper — a highly conductive and malleable material that is notoriously difficult to print via powder bed fusion processes, mainly due to cracking issues that result from the type of lasers equipped in most PBF machines.

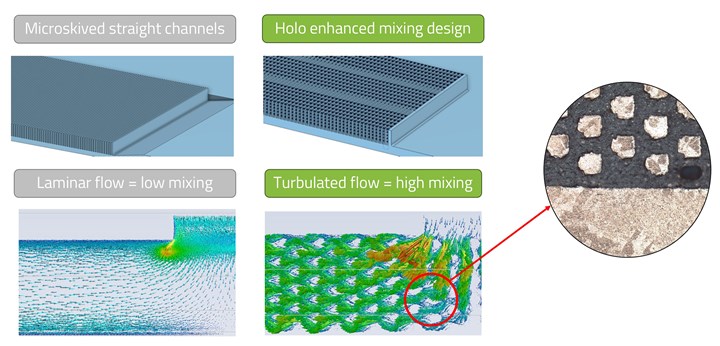

This diagram depicts cooling flow channels in a traditionally manufactured coldplate and one that is 3D printed. Holo’s design includes small part features that are meant to encourage turbulated flow and increase performance. Photo Credit: Holo

Traditionally, cooling plates are manufactured via skiving (or microskiving), in which metal material is sliced from a workpiece to form dozens of fins as thin as 110 microns each, and spaced roughly that same distance apart. Due to the constraints of cutting toolpaths these fins are machined as straight-line geometries, a condition that creates a smooth or laminar flow of the air or liquid across the fins meant to cool the device.

From a heat-transfer perspective, this type of flow is less than ideal. A laminar flow through a straight channel creates boundary layers that fall along each side of the fin, decreasing the effectiveness of the overall part. “So we kind of went back to fundamental-driven-design,” Aghababaie says. “We take the physics of what is happening in the real world, and then because we're not limited from geometry perspective we can now optimize around fundamental physics.”

Secret Sauce

The ability to create complex structures that compose a manifolded microchannel coldplate for liquid cooling is one part of the argument for 3D printing these parts. The other is the ability to redesign them in a way that dramatically increases performance. For example, one of Holo’s coldplate designs includes several crossmembers that run along the fin structures. Each of these crossmembers is uniquely designed with different densities, which vary according to the locations of hotspots on the chip and the desired flow distribution of coolant within the manifolds.

“What we end up having is something that has twice the flow mixing capability and twice the heat transfer of the traditional device,” Aghababaie says.

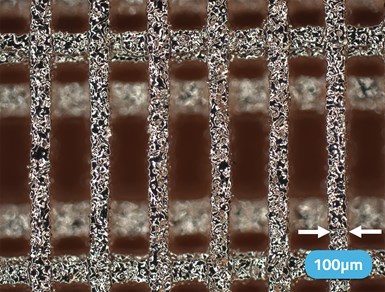

A closeup of the crossmembers, each uniquely designed with different densities to control flow distribution of coolant within the manifolds.

Photo Credit: Holo

The active area of the coldplate in this example — the area that enables cooling — is printed as a single 30 by 30 mm piece. This section also includes hundreds of tiny pyramid-like structures that Aghababaie calls chevrons, each roughly 150 microns tall, that are embedded across the fins throughout the device. These chevrons serve as flow disrupters, increasing the turbulation of coolant within the manifold. The fact that the manifold structure sits atop these chevrons makes the part nearly impossible to produce any other way. Even PBF printing could risk loose powder particles becoming stuck within the fin walls.

Aghababaie says that while Holo’s hardware and its use of DLP printing is similar to other DLP processes that have been around for years, it is the Holo printers’ ability to create uniform layers that set it apart. That uniformity is entirely dependent on the dispersion of the company’s “secret sauce” — the uniform layer thickness of the feedstock that allows the machines to cure new layers in less than 10 seconds.

For now, however, the company is still working toward driving down the thickness of the coldplate fins, which can be traditionally manufactured at 110 microns. The width of Holo’s 3D-printed fins is currently 170 microns. It’s the part’s design changes, Aghababaie says, that allow the part to achieve a higher performance level than traditional devices. “As we drive this down to 100 microns in our side, that improvement is going to effectively double again. So we would expect to see a four-times improvement relative to the traditionally made device.”

Junk In, Junk Out

The challenge with DLP printing — or for that matter, binder jetting or metal injection molding — is that you're effectively taking a powderized material, adding contaminants, and then trying to create a pure, high density, high fidelity part.

The good news is that powder metallurgy and process parameters for debinding and sintering — and the MIM furnaces themselves — have been calibrated or established for many years.

Aghababaie says Holo adds the optimization of its photopolymer binders to this mix. Holo’s photopolymer binders are designed in-house, while the company works with partners to source its powders before creating its final feedstock, which the company calls Pureform. While Holo is today focused on copper, its first Pureform material was stainless steel.

This initial focus on stainless steel was simply pragmatic: It’s a highly characterized, well understood material with abundantly available documentation about qualification processes, including hard data related to the mechanical and chemical properties that need to be achieved. There are also multiple grades of stainless steel available, which allowed Holo engineers to characterize different effects of carbon and other contaminants throughout Holo’s production process. “And that work has not been forgotten,” Aghababaie says. “In fact, we are now moving back into stainless as we are maturing our technology platform.”

The move into copper, however, presented unique challenges. With stainless steel, the predominant requirements revolve around mechanical properties. With copper, the predominant requirements center around thermal and electrical conductivity. Understanding carbon control was important to Holo’s development of its stainless-steel feedstock, Aghababaie says, but when the company refocused its efforts on copper, “we realized that there were other contaminants that would affect the conductivity requirements.”

The conductivity of copper — its performance, in the final sense — is directly related to its purity. Any contaminant, but especially iron, will undermine its most highly valued characteristic. For Holo, this meant conducting a robust vetting of its potential copper powder suppliers. “It's effectively a junk-in, junk-out situation,” Aghababaie says. “Selecting a supplier that offers the right chemical properties of its powders is key, because you either have to reduce or remove those contaminants through the sintering process or you're not going to be able to get the characteristics you need.”

Cross sections of Holo’s copper heat exchangers with varying unit cells using topology optimizations. Photo credit: Holo

The second piece of the feedstock-contaminant puzzle relates to photopolymer binders that Holo creates, which differ from the wax-based materials used in the metal injection molding. Certain chemicals in MIM binders affect either the mechanical or the chemical properties of the sintered parts, Aghababaie says, which makes the selection of the right photopolymers and monomers crucial. “Getting that perfect Venn diagram for something that's going to be ultimately printable and rigid, and something that's going to be low contaminant and be sinterable — and finding your sweet spot in the middle takes time,” Aghababaie says.

Sometimes, finding that sweet spot requires a tradeoff. What if the photopolymer has a contaminant, but that contaminant can be removed by using a specific gas during the sintering process? “We have both dials that we can turn, and that's been to our benefit,” Aghababaie says. “Because we can now optimize the process for both printing and sintering.” The number-one contaminant to be avoided here is carbon, which can inhibit the densification process during sintering.

Aghababaie says that, much like with any DLP process, Holo’s parts come out of the printer in a greenstate (about the consistency of a crayon in their case) that is washed in a solvent to remove excess feedstock. The part is then placed in the furnace for debinding to remove any excess polymer, before the temperature is increased for sintering.

“The densities that we're achieving are on average 96% to 98%,” he says — enough to hit the thermal and electrical conductivity rates of 95% for bulk copper.

A Shift to Stainless

As a business model, focusing initially on one material and essentially one market — cooling devices for high-power processors — has allowed Holo to flatten certain learning curves as the company tries to grow its business. Many of these cooling devices have similar designs — even if they are new designs — which means that Holo doesn’t have to worry about testing wildly variant designs and geometries. Of course, because the company is creating thermal management solutions, it will not be switching its base material. The ability to maintain these parallel focuses, Aghababaie says, opened the bandwidth for Holo to deal with other challenges. Namely, three of them.

Holo employees stationed at the company’s three DLP 3D printers. Photo Credit: Holo

The first challenge is material density. Because these parts are liquid cooling devices, the printed parts must be fully dense and hermetic. Even small leaks could lead to a catastrophe. Aghababaie says that the company was able to concentrate on developing and testing certain behaviors in its production processes, namely its printing technology and sintering, to ensure that it was repeatedly achieving sufficient densities.

The second, parallel challenge is thermal conductivity. This includes all of the considerations about contaminants outlined above that are critical to the performance of end device.

Finally, the third challenge is resolution. These thermal management devices require maximizing surface area — the smaller the features, the higher the surface area, the better the performance. Aghababaie says that Holo has been able to squeeze layers down to a 25-micron Z resolution, which in turn speeds up the overall printing time.

Holo is working to expand its material development — not only back to stainless steel but also aluminum and ceramics. Aghababaie believes that the company’s strategies so far will enable it to move swiftly.

“We’re in the early stages right now,” he says. “But we see areas where our technology is particularly well suited to materials that are traditionally challenging with other 3D printing technologies. Now we can take all of that learning and apply it to other materials. Having the same thought process and premise allows us to move quickly into these other spaces. We've had some early successes, but we've got a little way to go.”

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreSemiconductors, Tungsten, AM Affordability and More from Formnext 2024: AM Radio #56

The trade show included increased applications for the semiconductor market, machine launches and technology advances aimed at cost cutting, plenty of LFAM and more. Listen to our conversation on Formnext 2024.

Read MoreWith Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read MoreSintavia Plans $25 Million Expansion in Hollywood, Florida

The investments in facilities and equipment will power company’s growth over the coming years, including being able able to meet the demand from the programs it supports for the U.S. Department of Defense.

Read MoreRead Next

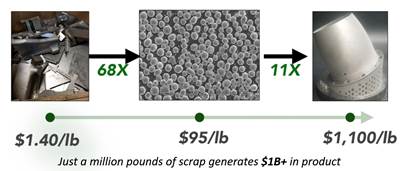

Is Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read MoreAM 101: Digital Light Synthesis (DLS)

Digital Light Synthesis (DLS) is the name for Carbon's resin-based 3D printing process. How it works and how it differs from stereolithography.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More