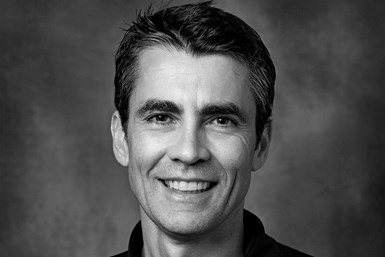

Formlabs Appoints President of Health Care Business Unit

As new health care president, Guillaume Bailliard will work to expand the company’s medical and dental business unit.

Share

Formlabs has appointed Guillaume Bailliard president of the company’s newly formed health care division. It is said the company has pioneered 3D printing accessibility in dental and medical industries, having sold more than 25,000 health care 3D printers, making it the most installed 3D printing company in the market.

With the formation of this new division, Formlabs says it is sharpening its focusing on the fast-growing 3D printing health care market, enabling the company to better serve providers, medical device firms, and clinician and patient needs.

It is said the health care sector is rapidly embracing the value and benefits of 3D printing in medical and dental applications — from personalized care and medical devices to real-time modeling and patient education. Rising public support and funding for 3D printing in health care, and adoption of digital workflows and manufacturing, has set the stage for 3D printing to grow in these markets.

The affordability and accessibility of Formlabs’ 3D printing solutions and materials have enabled medical and dental applications to flourish as a flexible solution that also meets the requirements for medical devices, dentures, implants, prosthetics and more, the company says.

The company says it has key partnerships — including becoming the first 3D printing company listed in a major group purchasing organization (GPO) catalog — which positions it as a leader in the market. With the appointment of Bailliard, Formlabs says it is strengthening its focus on delivering 3D printing solutions to support advancement in medical and dental applications.

Bailliard brings more than 25 years of experience in the health care market, having previously served in a variety of leadership roles in early-stage health care companies and within GE Healthcare for nearly a decade. In his new role, Bailliard will further build out the business unit to address both markets, creating a global growth strategy spanning product development and go-to-market planning.

Related Content

-

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

-

3D Printed PEEK Spine Implants in Production: The Cool Parts Show Bonus

Curiteva is using Fused Strand Deposition to produce two different lines of FDA-cleared spine implants. We visited the company’s Huntsville, Alabama, facility to learn more.

-

Ice 3D Printing of Sacrificial Structures as Small as Blood Vessels

Using water for sacrificial tooling, Carnegie Mellon researchers have created a microscale method for 3D printing intricate structures small enough to create vasculature in artificial tissue. The biomedical research potentially has implications for other microscale and microfluidics applications.