AM 101: What is Ultrasonic Additive Manufacturing?

Going from additive to subtractive can be simple with Ultrasonic Additive Manufacturing (UAM). What is it and how does it work? Learn the basics in this 101 post.

Share

How Does Ultrasonic Additive Manufacturing Work?

This process, with minimal heating, results in a solid-state atomic bond or weld between the thin metal tape and the substrate. Multiple layers are welded together one after the other to build up height. Photo Credit: Fabrisonic

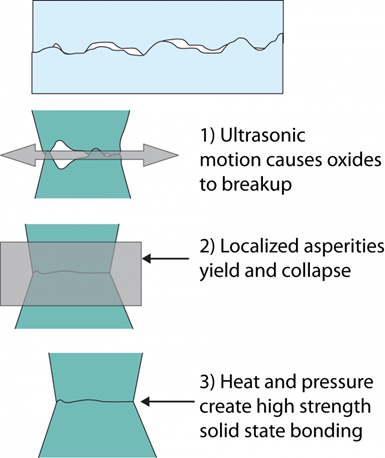

Ultrasonic additive manufacturing works by layering thin metal sheets or tape which are then vibrated together until they fuse.

In UAM, material is not melted, but instead joined through ultrasonic welding. This welding uses high-frequency vibration to join surfaces while the metal remains solid. By welding layer upon layer upon layer in this way, the process builds solid, dense metal parts.

While under high-frequency ultrasonic vibration and constant pressure, the ultrasonic motion breaks up oxides through friction, enabling the direct contact of metal on metal.

And as Mark Norfolk of Fabrisonic said in the first episode of The Cool Parts Show, “As soon as you have virgin metal touching virgin metal, mother nature takes over and you get a solid-state bond.”

This solid-state bond can be formed even between dissimilar metals, allowing for the creation of multimaterial parts that combine materials, like copper for cooling inside an aluminum part. The process repeats until a solid part has been built.

The Fabrisonic ultrasonic additive manufacturing machine has a work envelope of 6 × 6 × 3 feet. Developed by Fabrisonic, the machine is built by Ultra Tech Machinery, another Ohio Company.

Can Ultrasonic Additive Manufacturing Be Combined with Other Processes?

UAM can be combined with CNC machining in a hybrid format to enable cutting features and finish machining during the manufacturing process. Hybrid machines are available for this process that offer CNC contour milling to obtain required tolerances and optimal surface finish.

Ultrasonic additive manufacturing can also be used in conjunction with other additive manufacturing processes, such as augmenting an intricate part made via laser powder bed fusion with layers of similar or dissimilar materials.

What Materials Can Be Used with UAM?

Ultrasonic additive manufacturing is compatible with a wide range of metals, including alloys of aluminum, copper, magnesium, nickel and titanium.

Why Use Ultrasonic Additive Manufacturing?

The solid-state process makes it easy to embed sensors or other objects into solid parts. The build is simply paused as the embedded object is added, then the build continues to seal it inside.

The bonding temperature for all metals is below the melting temperature, which avoids problems with thermal deformation.

UAM also provides a reliable way to join dissimilar metals without creating brittle metallurgy. A hard metal outer surface could be built onto a structure made from a lighter metal to provide a part with both durability and light weight. Or, two very different metals — titanium and aluminum, say — could be combined in shuffled layers to create a structure that mixes the properties of both.

This technology combines the usefulness of additive and subtractive manufacturing, allowing parts with complex geometries and internal passageways to be built. The fine dimensional accuracy and smooth surfaces of the parts built with UAM and machining prove the possibilities of hybrid manufacturing.

Related Content

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

Read MoreVideo: Intelligent Layering Metal 3D Printing at 3DEO

Contract manufacturer 3DEO delivers metal parts using Intelligent Layering, a binder jetting-like 3D printing process the company developed and operates internally. Here’s how it works.

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreRead Next

This Rocket Fuel Injector Is a Solid Part That Contains a Working Motor: The Cool Parts Show #1

Our new video series debuts with a look at a solid metal part made through additive manufacturing that was built with a motor embedded inside. The motor sealed within the part adjusts the rocket’s fuel mixture while the rocket is in flight.

Read MoreHigh-Frequency Production

The additive process that grew out of ultrasonic welding provides an efficient way to produce complex work, including parts with embedded components and even parts made from dissimilar metals.

Read MoreAM 101: Hybrid Manufacturing

Additive manufacturing offers powerful capabilities alone, but even more opportunities are opened when AM is combined with subtractive processes.

Read More