High-Frequency Production

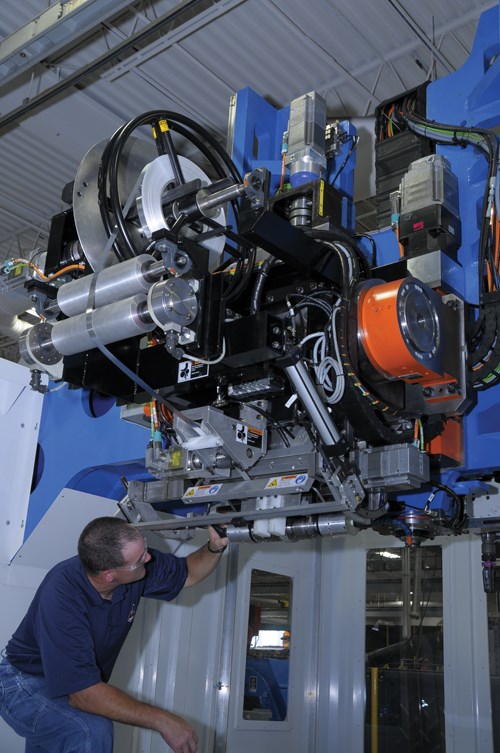

The additive process that grew out of ultrasonic welding provides an efficient way to produce complex work, including parts with embedded components and even parts made from dissimilar metals.

To gage how close additive manufacturing is to becoming a mainstream option for making metal parts, it is interesting to note this detail: Ultrasonic additive manufacturing machines from Fabrisonic of Columbus, Ohio, are programmed using a machining center’s CAM software.

Related Content

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read More8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More