Autonomous Underwater Vehicle With 3D Printed Hull: The Cool Parts Show #24

Our first episode of The Cool Parts Show from inside a 3D printer! Big Area Additive Manufacturing (BAAM) produces exterior components of a robot submarine and changes how this AUV is marketed.

Share

It had to happen. Large-format additive manufacturing (AM) systems are expanding their use and finding new applications — meaning The Cool Parts Show eventually would meet a cool part too big for the studio. For our first episode involving a part this large, we not only traveled to the part, we went inside the Big Area Additive Manufacturing (BAAM) machine used to produce it.

Additive Engineering Solutions (AES) of Akron, Ohio, used its BAAM capability to allow Dive Technologies to produce hull sections of its autonomous underwater vehicle (AUV) without tooling. Dive’s innovation is a AUV capable of long distances and long missions, such as mapping the ocean floor for a week at a time. The flexibility of producing hull components through 3D printing has allowed the Dive founders to realize another possible for this system: allowing AUV users to adopt hulls with different sizes or shapes as their needs change. | This episode of The Cool Parts Show brought to you by Carpenter Additive

The Cool Parts Show is a video series from Additive Manufacturing Media that explores the what, how and why of unusual 3D printed parts. Watch more here.

Have a cool part to share? Email us.

Related resources:

- Dive Technologies

- More on the Dive AUV

- Additive Engineering Solutions

- More of our coverage of AES

- How AM changes the “mold moment”

- BAAM (from Cincinnati Incorporated)

- Fiber-reinforced 3D printing polymer (Sabic)

Transcript

Peter Zelinski, Additive Manufacturing

On this episode of The Cool Parts Show, we're taking you inside this big 3D printer!

Stephanie Hendrixson, Additive Manufacturing

The Cool Parts Show is brought to you by Carpenter Additive. The company's Athens, Alabama Emerging Technology Center is an end-to-end additive manufacturing production facility with everything from materials development through post-processing under one roof, ready to help you with your next metal 3D-printing job. Check them out at CarpenterAdditive.com. Now, back to the show.

Peter Zelinski

I'm Pete.

Stephanie Hendrixson

I'm Stephanie.

Peter Zelinski

Welcome to The Cool Parts Show, our show all about cool, amazing, disruptive, transformative parts made through 3D printing, made through additive manufacturing.

Stephanie Hendrixson

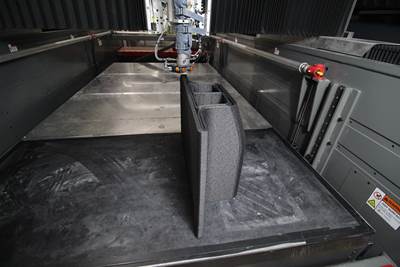

Today we are in a different geographic location. We are at Additive Engineering Solutions, AES, here in Akron, Ohio. But more specifically, we are sitting inside of their Big Area Additive Manufacturing, or BAAM, 3D printer. This is our first episode inside of a printer, and we are here to talk about these parts.

Peter Zelinski

Two parts here, one inside the other. These are hull components of an AUV, autonomous underwater vehicle — think robot sub — usually AUVs are smaller than this. These are components of a large-size AUV — an AUV capable of larger payloads, longer missions. These are going to be components of an AUV that will be able to go deep in the ocean, days at a time, to do things like map sections of the floor of the ocean. These parts are going to go to Dive Technologies. This is a company that was founded just a couple years ago to explore that very promise, “what could really big AUVs do.” Additive manufacturing proved to be vital for their realizing their vision for these parts. But it is also bringing about a change, a dramatic change, to the way they even think about their product. Let's meet Dive Technologies. This is Bill Lebo. He is one of the cofounders of the company and also their chief technology officer.

Bill Lebo, Dive Technologies

Dive Technologies started in 2018 and was founded by a group of three engineers with experience in fielding and developing maritime vehicles and vessels. In 2018, we recognized there was a corner of the autonomous underwater vehicle market that was underserved and this was large autonomous underwater vehicles —vehicles ranging in sizes from 4 to 5 feet in diameter and 20 feet or longer. Large autonomous underwater vehicles like the Dive vehicle will be used primarily for ocean-floor mapping and seabed infrastructure survey. So these are companies that have plans for, or already have, existing infrastructure on the sea floor and need to survey the ocean bottom for pre-construction, but also to inspect the construction afterwards to make sure everything is in order. So the vehicle you see being printed here today is the Dive Technologies DIVE-LD vehicle. This is a 6000-meter-rated vehicle capable of 500 nautical miles of subsea transit and carrying a payload capacity of one cubic meter. The hull shape for this vehicle is complex in order to create a low-drag hydrodynamic shape, which is easily achieved through the 3D-printing process.

Stephanie Hendrixson

Bill said that the design for the hull they came up with is easy to make with 3D printing. But I wonder, were they always going to 3D print it?

Peter Zelinski

So no, that wasn't the starting point initially. To the extent they were thinking about manufacturing, they were thinking about conventional processes they were familiar with. They were thinking thermoforming for hull components like these.

Stephanie Hendrixson

Okay, so how do we get from conventional thermoforming manufacturing to the two of us sitting inside of a 3D printer right now?

Peter Zelinski

I guess it starts with prototyping. But I guess, really, it starts with tooling. They had a tooling moment, they had a mold moment. They got an initial quote on a thermoform mold tooling, set of tools. And it was it was eye-popping, it was expensive. And more than that, they realized once they committed to tooling, they're locked in on design, and they weren't sure they were ready to be locked in. They weren't sure they were done innovating yet. So they wanted a manufacturing process that would preserve their design flexibility. That's 3D printing, and that forced them to look differently at the 3D-printed prototypes they were creating. Realizing that these prototypes, they're actually good enough, they're effective enough, they could be end-use production parts.

Bill Lebo

So we started working with AES early in 2019 and developed our first prototype hull panels. We brought these in-house to test for both structural integrity and ocean pressure depth, and we also applied the coating to make them smooth. Initially, we thought this would be a prototype method. After putting the hull panels through rigorous testing, we realized we had a part we could use on our final production hull.

Stephanie Hendrixson

So that's really interesting. You know, I think that's kind of a familiar story for us. We've seen other manufacturers who kind of come to 3D printing as this great prototyping tool, but then somewhere along the way, maybe completely by accident, they discover that actually, those prototypes could be production parts.

Peter Zelinski

Right, right. Big 3D printers, large-format additive systems like this, they're on the same journey that we've seen for smaller-scale 3D printers. Initially doing prototypes, doing tooling, and then eventually shift to making production parts. That's probably a good place to pause. We haven't talked about this machine enough yet. What can you tell us about this machine, Stephanie? This B-A-A-M — BAAM — that we're sitting in?

Stephanie Hendrixson

Yeah, so the BAAM, The Big Area Additive Manufacturing system, built by Cincinnati Inc. This printer can make parts that are up to 12 feet long and 5.5 feet wide. This specific machine that we're sitting in was designed to print up to 3 feet tall. But there's a special configuration here at AES, there's actually a pit underneath the build platform that we're sitting on, that allows them to extend that z-height a little bit more. So they can print up to 100 inches, a little over 8 feet. This is an extrusion-style 3D printer. It uses pellet materials, so the kinds of plastic pellets you might use for injection molding, and it can put out a lot of material — like up to 80 pounds an hour. So between that big build volume, and that kind of throughput, you can build large structures like this pretty quickly. But I want to get back to your point about shifting from a prototyping or tooling mindset to production because, you know, most of AES work today is tooling. They make a lot of those large composite layup forms, concrete tooling, that sort of thing. Was there anything about their manufacturing process that had to change when they went to a job that makes end-use parts?

Peter Zelinski

Yeah, that's a good place to meet our hosts. Here is Andrew Bader. He is one of the co-founders of AES, the company that owns this BAAM, the company that owns the other BAAM's we see around us, and he can speak to the challenges they faced as they moved into direct part production using a really big 3D printer.

Andrew Bader, Additive Engineering Solutions

At a mile below the ocean surface, the vehicle will be subjected to some pretty extreme pressures. However, the vehicle’s hull is actually flooded, so there's equal pressure all around the panels. In more traditional AM fabrication, infill is generally used to make up for thickness, and if these panels had any infill or voids whatsoever, they would easily get crushed by the water pressure. We were able to get around this challenge through a single, solid, perimeter-bead design. So there will be no infill or voids of any kind. In the beginning, we also made some test coupons for Dive to pressurize and test and those were all successful. Also important was creating a surface that was hydrodynamic. As you can imagine, large-printed layers with all the peaks and valleys don't do too well for hydrodynamics. We looked into machining the surface smooth, but machining large, thin panels is very challenging to do and requires expensive tooling to do it right. So in the end, we printed as thin as we could, while maintaining a consistent width that we were aiming for. This created a higher-resolution surface that Dive Technologies was able to then apply a surface coating to and achieve a smooth surface.

Stephanie Hendrixson

Okay, so Andrew just addressed some of the requirements they had to meet with this project. Withstanding the pressure under the sea, the hydrodynamic shape of the hull — were there other design considerations they had to take into account?

Peter Zelinski

So yeah, there is the outer form that Dive Technologies worked with researchers at Virginia Tech to optimize, to get to just the right form for the target speed that they identified for this AUV. And that work continues actually. Because it's 3D printing, they can keep tweaking and refining the design, and they'll continue to do that. But there was this other design consideration they faced, this type of design optimization that's maybe really inherent to the nature of a large-format 3D printer. We know about assembly consolidation as one of the real wins of production 3D printing, and at one point, they got it down to just four prints. But that was too few, because here's the other optimization they had to do for their own manufacturing, for their own ease of use when they got the parts: They needed the parts to be manageable by people, like lifting them and moving them around. Some of the parts were just too big. So they actually increased the part count a bit, and we're to the point now where I believe there are five prints that make up the hull form.

Stephanie Hendrixson

Okay, so optimizing for function, but also for usability. Dive and AES have put all this work into getting the shape of this hull just right, cutting it into the right number of pieces. Are they done? Is this the AUV design going forward?

Peter Zelinski

So mostly yes, but in some ways, no. There's still room for refinement and in the AUVs that Dive has shipped so far, they've been able to take advantage of 3D printing to offer some design variations to different customers based on different applications. They’re free to do that. But that is design freedom still completely with Dive and still Dive exercising it. They've come to realize that there's this whole different way of thinking about their product.

Bill Lebo

When we finished building the vehicle in August of 2020, we stood back and had this “aha” moment that it didn't really matter what this vehicle looked like. We had developed the inside guts, the mechanics, the gear and navigation that would propel this vehicle in the water. But the outside shape and hull didn't really matter, and it could change from customer to customer. This led us to develop a concept called the AUV Kit. AUV Kit is that core set of navigation, communication and energy propulsion subsystems that we can then wrap a new vehicle around depending on the customer's needs. For example, if a customer needed to grow the vehicle by 3 feet, or change its diameter by a couple of feet, we can keep that same AUV Kit core components and reprint a new hull around it for that particular mission at a very low cost, and with a very fast timeframe.

Stephanie Hendrixson

Okay, so I think I got this. These are hull parts for an autonomous underwater vehicle, designed by Dive Technologies, 3D printed here at Additive Engineering Solutions in their BAAM 3D printer. This hull design has been optimized for hydrodynamics as it moves through the water. It's been optimized for the right part count to make it usable for Dive as they assemble the sub and then for the ultimate operators of the sub. And going through this process, experiencing the design freedoms with 3D printing, has led Dive to this kind of new model, where they don't just build subs, they provide the kit of equipment that goes inside, the guts of the sub, and then they can 3D print whatever geometry the hull needs to be. Maybe the customer wants it a little bit longer, a little bit wider, and they can adapt the design of their vehicles to whatever the customer might need.

Peter Zelinski

Yeah, awesome. Thank you. Thank you for watching this episode of The Cool Parts Show. Thank you to our hosts Additive Engineering Solutions. Thank you to AES for pausing their 3D printer long enough for us to film this episode. If you've got a cool part you'd like to share with us, it doesn't need to be this big. if you've got a printer you'd like to invite us inside of, email us CoolParts@AdditiveManufacturing.media.

Stephanie Hendrixson

If you like the show, we hope you will subscribe. If you're on YouTube, go ahead and click that bell icon to get notified about new episodes. You can find all of our existing episodes on the Additive Manufacturing YouTube channel or at TheCoolPartsShow.com

Related Content

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreAt General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.

Read MoreHow Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

Read MoreRead Next

The Challenge of Reclaiming Carbon Fiber for 3D Printing

Carbon fiber composite materials weigh significantly less than steel while offering comparable strength and performance. But recovering and recycling continuous fiber for additive manufacturing applications — without any effect on the mechanical properties — has proven extremely difficult. Here is how Oak Ridge National Laboratory is working to solve the challenge.

Read MoreLarge-Scale Thermoset Composite AM System Launched

The Reactive Additive Manufacturing (RAM) system is said to be the world’s first large-scale additive manufacturing system compatible with thermoset resins.

Read MoreOhio Business Sees Big Possibilities in BAAM for Tooling

A new startup built around a large-scale 3D printer aims to offer short lead times for large industrial tools.

Read More