Large-Scale Thermoset Composite AM System Launched

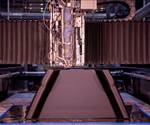

The Reactive Additive Manufacturing (RAM) system is said to be the world’s first large-scale additive manufacturing system compatible with thermoset resins.

Most large-scale 3D printing systems today use filament or pellet feedstock made from thermoplastics, meaning plastics that can be melted, solidified and melted again. But thermoset materials — plastics that retain their final solid form, like the resins used in SLA printers — offer potential benefits for large-scale prints such as increased strength and reduced cost compared to thermoplastic stock.

The newly launched Reactive Additive Manufacturing (RAM) system is said to be the world’s first large-scale additive manufacturing system capable of printing with fiber-reinforced thermoset materials. Developed by Magnum Venus Products (MVP; a manufacturer of composites application equipment), Polynt (a materials supplier) and Oak Ridge National Laboratory (ORNL), the RAM is capable of building thermoset parts measuring 8 × 16 × 3.5 feet. According to its developers, parts printed with the RAM system have good Z strength, thanks to polymer links that form cross layers, and equal thermal expansion in all axes.

While many thermoset materials require a UV cure, the Reactive Deposition PRD-1520 print media developed by Polynt for the RAM system is a reactive resin that cures at ambient temperature. In contrast to thermoplastic printers, the machine does not require a heated table or chamber, or a high-temperature extruder. Watch the video below to see it in action and hear from the machine’s developers.

The RAM is particularly well-suited to applications such as thermoforming tools and autoclave molds, though other applications are also being explored. Our sister publication CompositesWorld was on site for the RAM launch event in September. For more on this new development, read Senior Editor Ginger Gardiner’s report here.

Related Content

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

How Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

-

Video: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

.jpg;width=70;height=70;mode=crop)