The Challenge of Reclaiming Carbon Fiber for 3D Printing

Carbon fiber composite materials weigh significantly less than steel while offering comparable strength and performance. But recovering and recycling continuous fiber for additive manufacturing applications — without any effect on the mechanical properties — has proven extremely difficult. Here is how Oak Ridge National Laboratory is working to solve the challenge.

Modern wind turbine blade spar caps are often constructed of a nearly indestructible carbon-fiber reinforced composite material. As throughput capabilities increase for large area additive manufacturing, being able to reclaim and recycle these carbon fibers will be essential for AM — from both an economic and environmental perspective.

The scene has been compared to burial sites for bleached whalebones — landfills deep enough to swallow whole the 165-foot-long wind turbine blades that have reached the end of their lifecycle. Many of these blades are from the first generation of wind farms erected around the globe in the 1990s, composed of glass-reinforced thermoset composites that resist material recovery and recycling processes. Newer blades and their spar caps (molded shapes that form the interior skeleton of the blades) are often composed of carbon fiber or carbon epoxy reinforced materials — materials so tough that they will snap the steel teeth of industrial shredders that try to break them down.

The scene has something to say to industries well beyond wind power. As carbon fiber-reinforced composites are increasingly used for mass-produced parts in the aerospace and automotive sectors, the question of how to reclaim and recycle these materials becomes more pressing. Given large-scale additive manufacturing (AM) using carbon fiber-reinforced polymer continues to gain acceptance, the questions only multiply: Is it possible to mechanically break down carbon-fiber reinforced materials and recycle them for use in other AM applications? Or does the fiber become so degraded through this process that more complex and expensive procedures are needed to recycle it? And if that is the case, what is the value proposition? Is a circular supply chain for recycled carbon-fiber AM materials even possible?

Shredded Composite scrap materials (from left to right): a wind turbine blade spar cap; automotive parts; composite agriculture equipment waste; and glass fiber/vinyl ester composite from a wind turbine blade.

These questions loom large for researchers at the Oak Ridge National Laboratory (ORNL) and its partners at the University of Tennessee, Knoxville. And as a recent interview made clear, their work has only just begun.

The Footprint of Carbon Recovery

Dr. Soydan Ozcan, the Composite Recycling Lead at ORNL Manufacturing Demonstration Facility and a specialist in developing novel, high-value biomaterials from renewable sources, says that the need for composite material recovery processes is becoming critical as extrusion capabilities for large area additive manufacturing push the envelope from current rates of 100 pounds an hour, to ever-larger machines that will be able to print parts at a clip of 500 to 1,000 pounds an hour.

Reclaimed, chopped carbon fiber resulting from pyrolysis processes at Oak Ridge National Laboratory.

“Large area additive manufacturing is a growing manufacturing technique that is going to take over for many different types of processes,” he says. “When can you reclaim the material [from this technique] and put it back to into additive manufacturing? Can we can really control the impurity of these materials? What types of property challenges, what type of printing challenges, or what type of pore defects may be created with it? These are the questions we are dealing with.”

While most of the work taking place at Oak Ridge does not center specifically on AM, the core reclamation technologies remain valuable to the field. The U.S. Department of Energy has sponsored ORNL projects through the Institute for Advanced Composite Manufacturing Institute that is similar to the current research being conducted by Dr. Ozcan and his research partner Dr. Ryan Ginder, a research assistant professor at the University of Tennessee, Knoxville: Running mechanical tests on fibers to understand the degree to which mechanical properties have degraded. “So we can see that in glass fiber, depending on the thermal history of it, it will have degraded to some extent past the virgin fiber,” Ginder says. In fact, one of Ginder’s recent studies looked at fibers that went through a sheet molding compound process and found that the process itself had a damaging impact on the fiber. In other words, the fiber that his team recycled was compromised from the beginning — its original strength was degraded before it was put to use.

Another ongoing study is examining the pyrolysis process in which thermal energy is used to break down the resins and recover the contained fiber. These resins can be converted into energy while the fiber is recovered for production of recycled composites. Because carbon fiber can generally withstand pyrolysis processing, the business of recycling carbon fiber through pyrolysis is growing. But, Ginder says, one issue for the market remains: Even if we can recover this fiber in some form, how do we actually re-use it?

“How can you take this now released, puffy, fluffy fiber and convert it back into intermediates that can be readily used for manufacturing new composites,” Ginder asks. “And to what extent are the properties like stiffness and strength compromised by the recycling process?”

Tests include breaking the pyrolysis processing step, which is typically conducted in one, very high temperature treatment, into separate low and high temperature steps — effectively reducing the level of aggressiveness with which the fiber is treated in order to preserve its strength for re-use. Ozcan and Ginder have already found success in taking a recycled carbon fiber through pyrolysis reclamation and using it to produce Class A automotive body panels.

Again, this particular research was not directly related to additive manufacturing — but has important repercussions for its future, according to Dr. Ozcan. “A lot of the cost of additive composite materials is in that carbon fiber,” he says. And if it’s possible to produce a recycled fiber that has the essential properties intact — but at a substantially lower price point compared to virgin material — then it becomes possible to bring down the cost of these additive manufacturing materials while reducing the carbon footprint of the process. “The embodied energy of recycled carbon fiber versus virgin material is orders of magnitude smaller,” Dr. Ozcan says. “Since we can get the fiber back in a state that is essentially reusable as reinforcement, both from an environmental and economic standpoint, I see a strong, compelling case for continuing this research for additive manufacturing.”

Related Content

Concept Sneaker Boasts One-Piece 3D Printed TPU Construction

The Reebok x Botter Concept Sneaker Engineered by HP premiered at Paris Fashion Week, hinting at manufacturing possibilities for the future of footwear.

Read MoreVideo: AM for Repair of Large Shafts

Wind power shafts that might once have been scrapped are now returned to service. See the robotic directed energy deposition (DED) and shaft preheating system developed by Ikergune, Izadi and Talens.

Read MoreVideo: AM for Harder, Longer-Lasting Brake Discs

Additive manufacturing is being applied to limit automotive brake dust. For a major automaker, Etxetar and Talens are developing a production-speed directed energy deposition system to give brake discs a precise layer of wear-resistant carbide.

Read MoreBMW Expands Use of Additive Manufacturing to Foster Production Innovations

The BMW Group is manufacturing many work aids and tools for its own production system using various 3D printing processes, with items such as tailor-made orthoses for employees, teaching and production aids, and large, weight-optimized robot grippers, which are used for such things as carbon fiber-reinforced polymer roofs and entire floor assemblies.

Read MoreRead Next

Why “Recycled” Doesn’t Mean Inferior for 3D Printing Filament

GreenGate3D’s PET-G filament is made from recycled plastic, but that doesn’t diminish its quality. How a recycler found a new business opportunity in 3D printing, and how this success might point the way to a more effective recycling ecosystem.

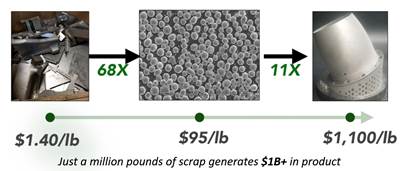

Read MoreIs Recycled Metal Scrap the Future Feedstock of Choice for Metal 3D Printing?

MolyWorks is future-proofing the circular economy for metals with small-footprint atomization technology that converts metal scrap into additive manufacturing powder on the spot. But that's not the end of the story.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More