3D Printed Tooling

Tooling refers to items that shape, form or hold material, or otherwise assist, some other manufacturing process. That includes injection molds, composite layup forms, sheet metal dies, foundry patterns and forms, workholding solutions, jigs, assembly fixtures, inspection fixtures, and hand tools. End of arm tooling for robots and other items that assist automation are an important application. Arguably, cutting tools fall here as well.

ESSENTIAL READING

VIEW ALLCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

ListenFord is Saving Millions through 3D Printing (But Maybe Not How You Think)

Two longtime workers at Ford’s Sharonville Transmission Plant near Cincinnati grew tired of experiencing the delays and downtime resulting from expensive and hard-to-get replacement parts. The solution? Learn additive manufacturing and save the company time and money.

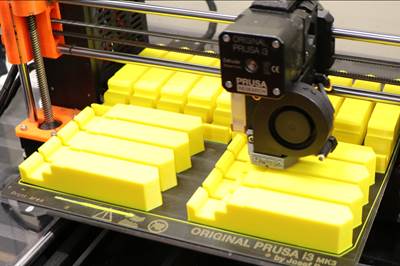

Read More10 Examples of 3D Printed Tooling

Additive manufacturing can aid conventional manufacturing through the production of tooling. This article showcases 10 clever uses of 3D printed tooling.

Read MoreVideo: Additive Manufacturing Offers a Tooling Alternative

3D printing can offer a cost-effective alternative to conventionally produced tooling for those processes that depend on it.

WatchLatest Tooling News And Updates

Massive Dimension Becomes Authorized Integrator for FANUC Robots

Massive Dimension can now integrate FANUC’s robotics technology to enhance its additive manufacturing offerings, enabling more customized solutions tailored to specific customer requirements — from prototyping to full-scale production.

Read MoreMantle’s 420 Stainless Steel Material Improves Toolmaking Processes

The hard strength material enables engineers and manufacturers to produce production-grade tooling up to 80% faster — enhancing strength, corrosion resistance and polishability for diverse applications, particularly medical devices and conformal cooling components.

Read MoreAirtech and AES Collaborate to Grow Large Format Additive Manufacturing Applications

As part of the partnership, Airtech will provide comprehensive support to AES in additive manufacturing business opportunities and technical areas, while AES commits to exclusive use of Airtech products in its LFAM projects to ensure high quality and performance standards.

Read MoreHP, GKN Additive Partner to Qualify Diverse Range of Materials for Additive Manufacturing

The collaboration focus is to combine HP’s Metal Jet S100 technology with unique material offerings to take tooling to the next level while addressing unique customer challenges.

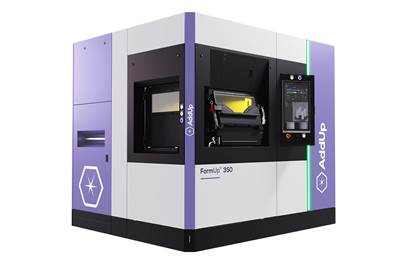

Read MoreAddUp, WBA Investigate Additive Manufacturing for Moldmaking Tooling Study

The additive manufacturing (AM) tooling study focused on six select companies, offering them the opportunity to test the introduction of AM and specifically implement the technical and economic advantages of AM technology for their injection molds.

Read MoreDOE Awards Nearly $3 Million to Develop Additive Manufacturing of Modular Wind Blades

The industry partners received the award to develop automation in additive manufacturing of tooling for large-scale wind blades that can accommodate continuous changes in blade geometry and scale.

Read MoreFeatured Posts

Forerunner 3D Supports Automation with 3D Printed EOAT

The custom 3D printing company uses 3D printing in combination with other technologies to deliver end of arm tooling for part handling.

Read MoreHow 3D Printing Aids Automation, and How Additive Will Reach Farther With Robots: AM Radio #55

Robots & Autonomy editor Julia Hider joins the AM Radio podcast for an episode all about the ways that 3D printing and robotics are advancing and assisting each other.

Listen3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreFeatured Media

Robot Vs. Gantry for Large-Format Additive Manufacturing (Includes Video)

Additive Engineering Solutions, specialist at 3D printing very large parts and tools on gantry machines, now also uses a robot for large-format AM. Here is how the robot compares.

WatchVideo: 3D Printed Tooling Eases Cobot Integration

At NPE 2024, Universal Robots and EMI Corporation highlighted how 3D printed end effectors, fixtures and more enable adoption of collaborative robots.

WatchCopper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

ListenFAQ: Tooling

What is tooling?

For Additive Manufacturing Media’s purposes, tooling refers to items that shape, form or hold material, or otherwise assist, some other manufacturing process.

What is EOAT?

EOAT stands for end of arm tooling. This is the component of an automation system that interacts with the workpiece. For example, in injection molding this is typically a vacuum gripper or gripper fingers that remove parts from a mold. Source: 3D Printed End of Arm Tooling Aids Automation

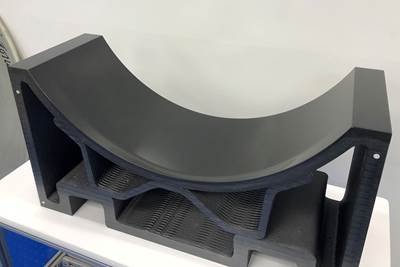

What is conformal cooling?

Conformal cooling is distributing cooling fluid through channels that follow the shape of a part, rather than straight-line channels that are drilled into a part. Conformal channels can be 3D printed into mold tooling as seen here.

What are 3D printed tools made of?

3D printed tools can be metal, polymer (especially reinforced polymer), ceramic or sand in the case of foundry tooling.

What are examples of tooling?

Tooling includes injection molds, composite layup forms, sheet metal dies, foundry patterns and forms, workholding solutions, jigs, assembly fixtures, inspection fixtures, and hand tools. End of arm tooling for robots and other items that assist automation are an important application. Arguably, cutting tools fall here as well.