You Are Here

Different types of additive machines are at different places along the curve of technology’s adoption.

I rarely use “subtractive manufacturing” as a term that meaningfully unites a set of technologies. After all, metalcutting machining centers and woodworking routers are both “subtractive” machines, but their uses are so different that they are rarely lumped together. It’s hard to see what value would come from the lumping.

That observation suggests the kind of faulty thinking that can arise when “additive manufacturing” is used (as it often is by the general media) as an inclusive term for all digital 3D layering equipment—as if there is any meaningful trend or conclusion that all of this equipment is subject to.

In this publication, we use the term to refer to the industrial use of additive technologies to produce functional and often high-value engineered parts. That definition separates a direct metal laser sintering machine, for example, from a low-cost desktop 3D printer—even though both are “additive” and both have a place in “manufacturing.” The only thing uniting these two machine types is digital layering, and that is not much to have in common.

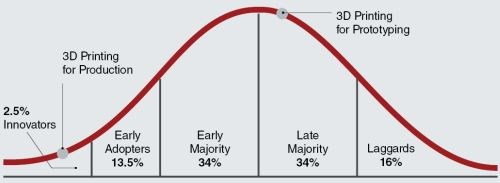

At the most recent SME Rapid conference, Terry Wohlers, president of Wohlers Associates, gave a speech in which he shared the graph on this page. It illustrates why lumping all 3D printing into a single category leads to false impressions.

This graph is the technology-adoption distribution curve created by Everett Rogers in the 1960s. Senior manufacturing professionals might remember when now-established manufacturing technologies (think of EDM and CNC) were progressing through earlier stages on this curve. And on this curve, Wohlers tried to place his guess for where the adoption stands for 3D printing both for prototyping and for mature production. I agree with where he placed both dots, but the larger point is this: These two different dots are very widely separated along the curve.

Breathless coverage of additive manufacturing in the media conveys the impression that manufacturing in general has widely embraced and is rapidly adopting digital-layering forms of part creation. The truth is: 3D printing has been widely embraced for prototyping, including prototypes that capture only the part’s shape and not its function. When it comes to production, additive manufacturing has a ways to go. There are still basic questions to be asked and overcome for all who would use the technology in this way.

That’s OK—a growing number of manufacturing innovators are facing those very questions, because the promise of additive manufacturing is clear. Without overstating the extent of the technology’s use so far, this publication aims to cover the answers those innovators are finding.