Case Studies of Multi-Material Manufacturing

Tools for injection molding, die casting and powder compaction all illustrate the potential to achieve greater part performance and manufacturing efficiency by blending workpiece materials through AM.

Editor’s Note: Direct Metal Deposition (DMD) systems developed by DM3D Technology build metal parts by injecting powder into a weld pool created by a laser. One of the possibilities is multi-material manufacturing. A dual-hopper capability of these systems allows for controlled deposition of multiple materials on a single part. This means, for example, that a part can be designed and created to offer high toughness at the core combined with fatigue, wear or corrosion resistance resulting from some different material at the surface. DM3D’s Bhaskar Dutta reports on the following case studies illustrating some of the applications of multi-material manufacturing.

Case Study I: Injection Mold Tooling

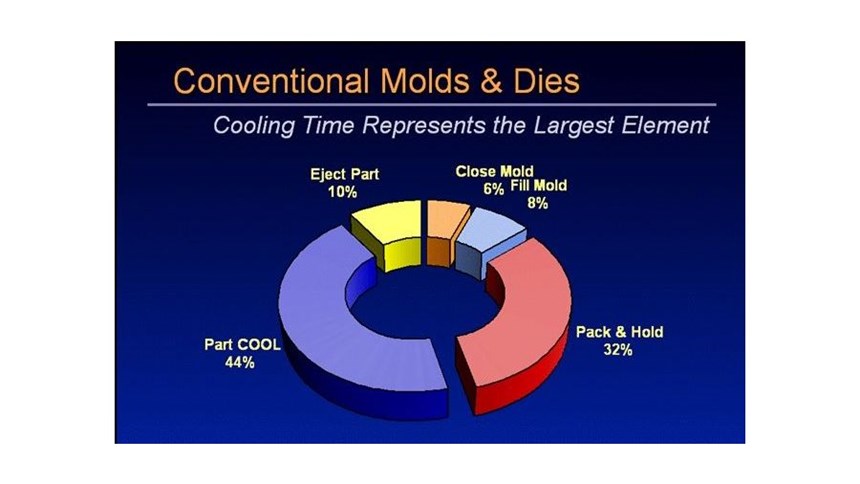

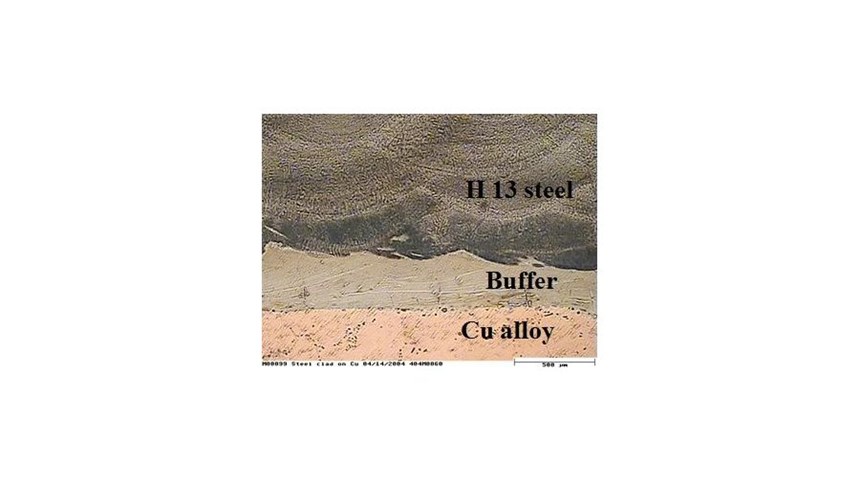

Figure 1 in the sequence of illustrations above shows the shows cycle time breakdown typical of plastic part molding. As the diagram shows, part cooling time after plastic injection affects the total cycle the most (44 percent), meaning a reduction in cooling time would have greatest impact on productivity. Figure 2 shows a tool used for making seat belt clamps in cars. The tool has been made from tool steel cladded on a copper base using DMD. The thermal conductivity of copper alloys is almost 6.0 times that of tool steels. This conductivity allows the copper base to work as a heat sink, providing fast cooling of the part for a significant reduction in cycle time. Meanwhile, the steel clad on the molding surface provides the required strength and wear resistance of the tool.

The key to this cladding is successful joining of copper and steel. Conventional welding techniques can’t join these materials together. DMD joins them with a laser thanks in part to a proprietary buffer material. Figure 3 is a microscopic view of this cladding showing the buffer.

The steel-clad technology allowed this customer to reduce molding cycle time by 26 percent, achieving a 28-second cycle instead of 38 seconds with a conventional tool. That cycle time reduction translated to about $60,000 in savings per year per tool.

Case Study II: Die Casting Tooling

This work was performed in collaboration with Case Western Reserve University and the North American Die Casting Association.

Similar to injection molding, the efficiency of aluminum die casting is also affected significantly by part cooling time. The high temperatures and presence of liquid aluminum also pose other challenges to the tools. During casting, the core (usually made of tool steel) is surrounded by molten aluminum and overheats to the point that dissolution of the steel takes place (commonly called soldering in the die casting industry). Extracting heat more efficiently from the core can reduce the core temperature, prevent soldering and allow shorter cycle times. Figure 4 in the images above shows the aluminum part that was investigated in this study. Figures 5 and 6 show the composite core, which was made of copper alloy DMD-cladded with H13 tool steel using an intermediate buffer layer.

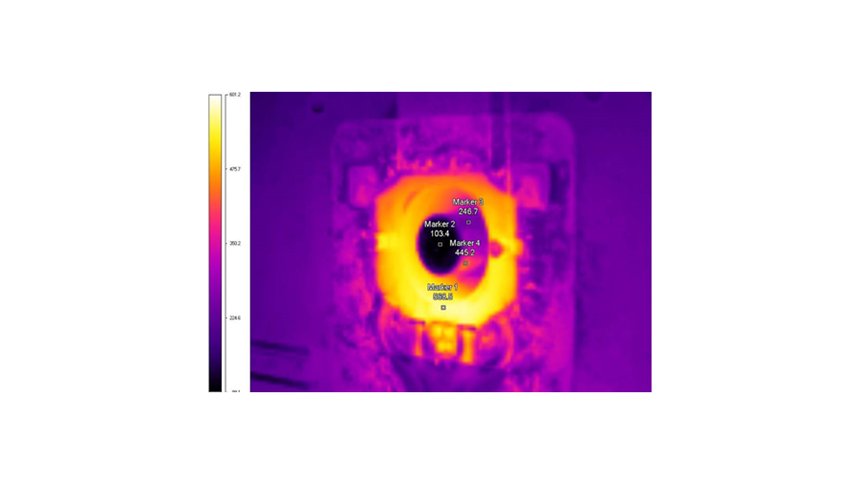

Figure 7 shows thermal imaging used to evaluate this composite core. Surface temperature was measured to be about 100oF lower than that of the conventional core. The benefits seen were a 13 percent reduction in casting cycle time (40 seconds for the H13/copper core versus 55 seconds for the purely H13 core) along with reduced soldering due to lower core temperature.

Case Study III: Powder Compaction Tooling

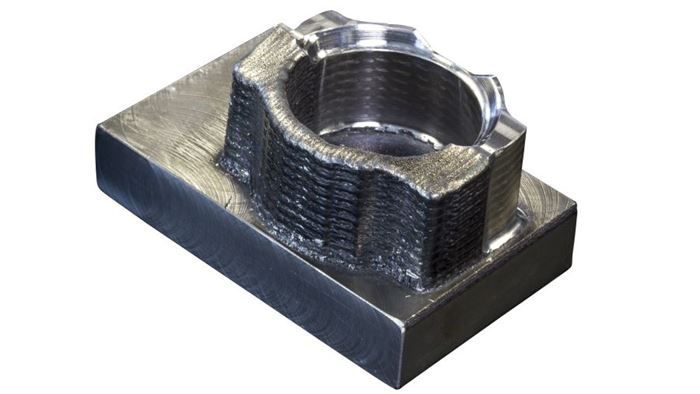

Powder compaction tools used in sintering undergo significant load cycling. Fatigue life of these tools is critical. Depending on the part design, a sharp radius in the tool geometry can act as stress concentrator, affecting the tool life significantly. Multi-material manufacturing technology offers an unusual solution for this problem. An alternate layering of hard metal and soft metal in the upper part of the tool is proposed to mitigate this stress-concentration problem. The lead photo in the series of illustrations above shows a sample of this. Fatigue cracks that arise at stress concentration points on the surface will be arrested when they propagate into the soft metal layer, while the presence of alternate hard metal layers provides the tool with the required stiffness and strength for metal compaction. This tooling technology is expected to aid in mitigating fatigue life problems with powder compaction tools.

Related Content

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More