Alpha Precision Group (APG) in Ridgway, Pennsylvania, has a history of manufacturing parts through powder metallurgy. Along with conventional techniques including press and sinter and metal injection molding (MIM), the company also uses a collection of metal 3D printing techniques including binder jetting, bound metal deposition (BMD) and now MoldJet to manufacture metal parts.

The MoldJet process developed by Tritone Technologies combines powder metallurgy with 3D printed wax molds used to form the green parts layer by layer. This video explores how this sinter-based additive manufacturing process works, and some of the use cases that APG is finding for this technology.

Transcript

I’m Stephanie Hendrixson with Additive Manufacturing Media. I'm learning about sinter-based additive manufacturing here at Alpha Precision Group, APG, in Ridgway, Pennsylvania.

This is a MIM company, a metal injection molding company that has adopted various types of metal 3D printing, including bound metal deposition, binder jetting, and this most recent addition. This is a MoldJet printer, the Dominant platform from Tritone Technologies.

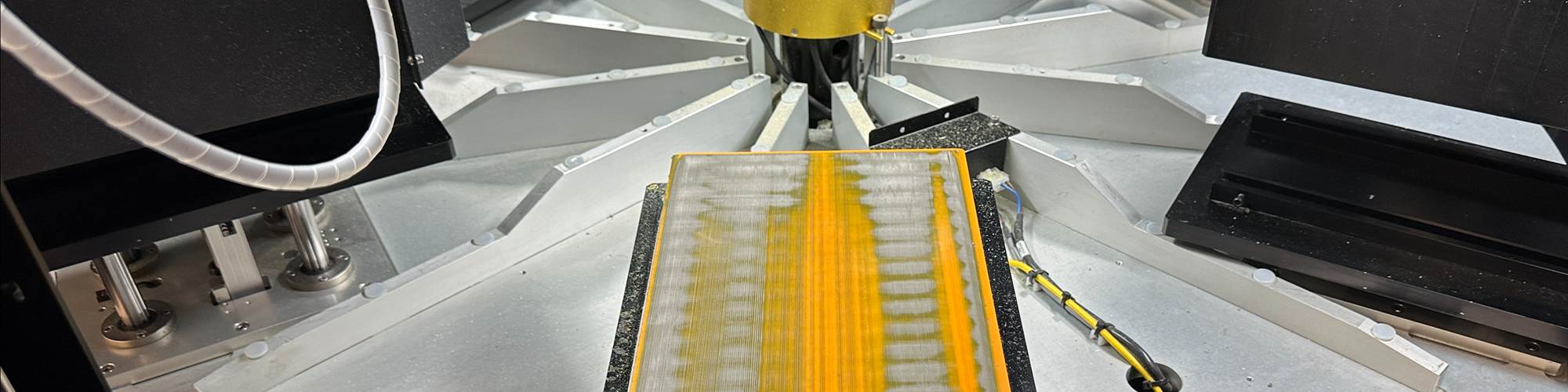

This machine uses a carousel system with multiple different stations to accomplish higher volume 3D printing of green metal parts.

It starts with a wax build platform that is first leveled. Once it's flat, the build platform goes to the print station where four different printheads are precisely dropping wax to basically build up a stencil, a mold for the ultimate metal part. The stencil is built up in layers that are 130 microns high, and then they are machined down to be exactly 100 microns.

Then there is a slurry, a paste of metal powder with some additives that is flowed into the mold to start building up the structure of the parts.

From there, the build platform travels to one of two drying stations. There are two inside the machine so that you can be running up to six different build platforms at once without wasting any time. And then each layer is inspected before the whole process starts again.

Once the build is complete, the entire build platform goes into an oven where the wax is melted away. And then finally the brown metal parts go through a sintering furnace to achieve their final part properties.

The Tritone process results in isotropic shrinkage, so it's predictable and parts shrink evenly from all dimensions.

APG is finding this machine and this technology useful for a couple of different applications. They're doing a lot of things to bridge customers from 3D printing into MIM. So this is a way to test out geometries and to experiment with sintering conditions before cutting the tool and going to metal injection molding.

But it also makes sense for certain end use components as well, especially those with complicated geometries that would be difficult to mold or difficult to make with binder jetting and those with complicated internal features where it would be too challenging to remove the powder from inside.

Some of the end use parts that they're making with this system include components for firearms, other industrial applications and situations where quantities are maybe in the hundreds to the thousands, where it doesn't make economic sense to go to metal injection molding.

Related Content

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreVulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreThis Year I Have Seen a Lot of AM for the Military — What Is Going On?

Audience members have similar questions. What is the Department of Defense’s interest in making hardware via 3D printing over conventional methods? Here are three manufacturing concerns that are particular to the military.

Read MoreRead Next

Binder Jetting Follows in Footsteps of Metal Injection Molding

For Smith Metal Products, additive manufacturing helps MIM customers finalize the design, but production opportunities are waiting.

Read MoreSinter-Based Additive Manufacturing Finds a Place Alongside MIM, Press and Sinter at APG

Powder metallurgy company Alpha Precision Group (APG) is applying a particular class of metal 3D printing technology for both rapid iteration in development and flexibility in production.

Read MoreUnusual Forms of 3D Printing, and How to Categorize This Technology: AM Radio #21A

In this episode of AM Radio, Stephanie Hendrixson and Peter Zelinski quiz each other on six 3D printing processes — some common, some novel. Test your own knowledge and stick around for a discussion about how to categorize (or maybe re-categorize) AM technologies.

Read More

.jpg;width=70;height=70;mode=crop)