Share

In 3D printing, “assembly consolidation” usually refers to a part’s design — that is, the decision to combine multiple components into a single 3D-printable part. This approach has potential benefits in terms of reduced labor, faster speed in manufacturing and sometimes even improved durability. However, there is a tradeoff: Larger parts have implications for machine utilization and efficiency. A larger, more complex part may take longer to produce, cost more and occupy a large footprint in the build envelope. That is why Zeeland, Michigan, manufacturer Extol has found that there are often very compelling reasons to split, rather than combine, parts that will be 3D printed. The company has been in operation more than 35 years as a supplier of plastics joining technology, services and systems, and understands well the various ways of assembling plastic parts together. The ability to join parts that were printed in pieces can make for far more efficient 3D printing builds. See an example and learn more in this video.

Learn More: Joining Product Development and Production Via 3D Printing

Manufacturing technology supplier Extol has always served customers who are producing polymer parts. Now, it is making some of those parts in-house through 3D printing, providing new options ranging from functional prototyping into bridge production and beyond. READ MORE

Transcript

I’m Stephanie Hendrixson with Additive Manufacturing Media. I'm here at Extol in Zeeland, Michigan. Extol is an additive manufacturer. They use several Multi Jet Fusion printers from HP to produce parts for their own internal use, as well as external customers.

But the main part of their business is joining together plastics, and that gives them an interesting perspective on additive manufacturing. We talk all the time in additive about assembly consolidation and the use of 3D printing to combine different parts together into one single print. And that's not always the best way to do things.

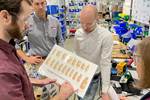

So because Extol has this equipment, they have this understanding of different ways to join plastic parts together. They take things that look like this and divide them into different pieces and then assemble them back together after the printing process.

So this is a custom scoliosis brace. It's produced for a customer called Fited, and it is 10 to 15 parts. Each one of these is made custom printed in pieces because those different pieces can nest together more easily than several large components like this. This component is printed from polypropylene. It is then ultrasonic welded together.

So this is mass customization, a production product that is made through additive but not assembly consolidation in the way that we typically think of it.

Related Content

-

What Does Additive Manufacturing Readiness Look Like?

The promise of distributed manufacturing is alluring, but to get there AM first needs to master scale production. GKN Additive’s Michigan facility illustrates what the journey might look like.

-

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

-

Understanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

.jpg;width=70;height=70;mode=crop)