Additive manufacturing (AM) has a design problem. The technology, which is digital enough to enable distributed manufacturing and flexible enough to support customization, still requires a working knowledge of CAD and design for AM (DFAM) to take advantage of its potential. That shuts out the average consumer who might simply want a customized piece of home decor, or need a specialized accessory or replacement part. Without the design skills to create or tweak a CAD file, the pursuit of a custom printed part becomes expensive and difficult.

However, even the most skilled designer developing an additively manufactured product is still likely to encounter AM’s other problem: production at scale. Creators may not have the time or resources to execute the manufacturing themselves at the volumes they’d like to reach. Those who want to offer custom products have an added challenge, because each new customization means touching the CAD file again. Even if creators begin by 3D printing parts themselves, achieving true scale can be difficult as an individual or small business.

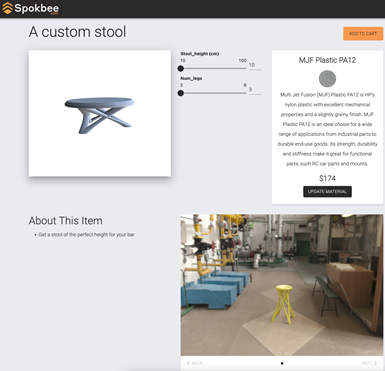

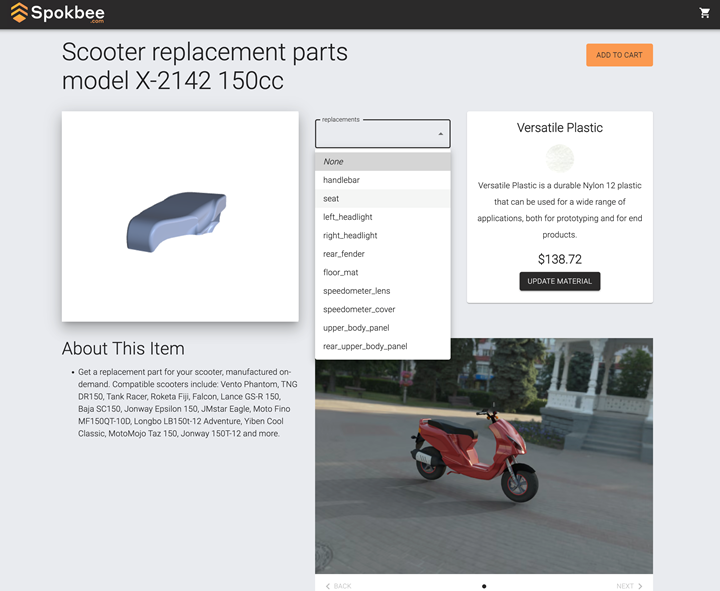

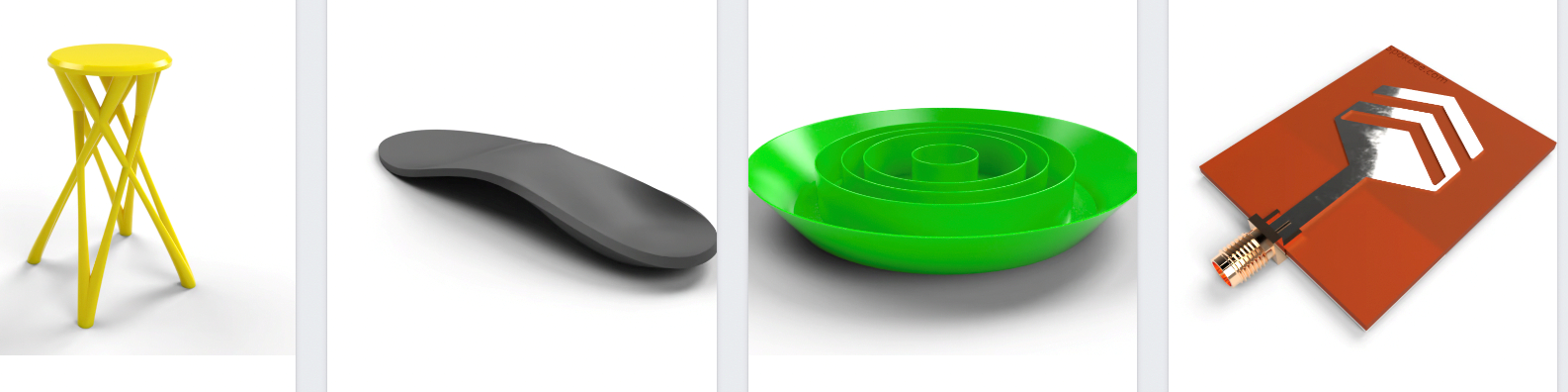

Spokbee’s online marketplace allows buyers to easily customize their items, no design skill necessary. Changes like increasing the number of legs for a stool, adjusting its height and switching materials take a matter of seconds, and pricing updates accordingly in real time. Screenshots: Spokbee.com

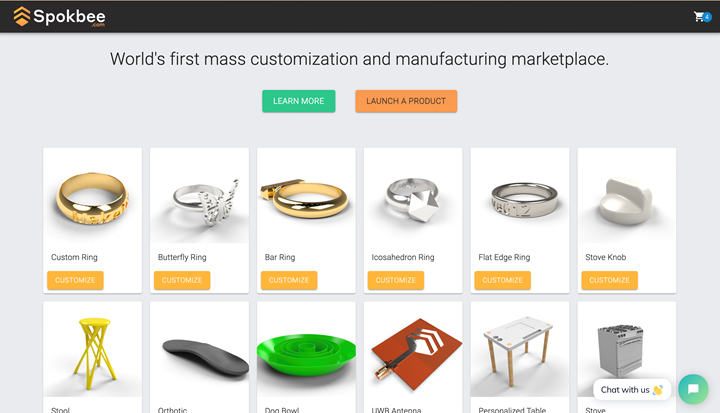

Spokbee’s "mass customization marketplace" is intended to solve both problems at once, on the one hand to deliver AM's customization powers to consumers who are not themselves designers, and on the other to empower skilled designers in any industry to launch and sell products without also needing to manufacture them.

“This is the last big gap in 3D printing technology to scale to large, widespread adoption,” says Mac Cameron, who cofounded the company in January 2022 with his wife, Karina, an experienced software developer.

As a university lecturer and former applications engineer at Stratasys, Cameron has seen both sides of this gap. College students, industrial designers and influencers in all kinds of niche industries are eager to launch 3D printed products, but can’t start or keep up with production. Meanwhile consumers and professionals need customized solutions but may not have the skills in CAD and DFAM to get there.

Spokbee could be the connection between them. The platform is an online marketplace that will allow designers to sell 3D printable products from their own storefronts, similar to Etsy. But rather than fill those storefronts with a selection of standard wares, store owners have the option to allow for parametric customization of their designs directly in the browser. Customers can modify products to their needs (altering the diameter of an accessory to fit their own vacuum, or changing the width of a ring band, for instance). Materials, colors and other options can be offered as well. Selections made change the price of the item in real time. From the buyer's perspective, it is a seamless, tailored experience from discovery through checkout.

Enabling Real-Time Customization

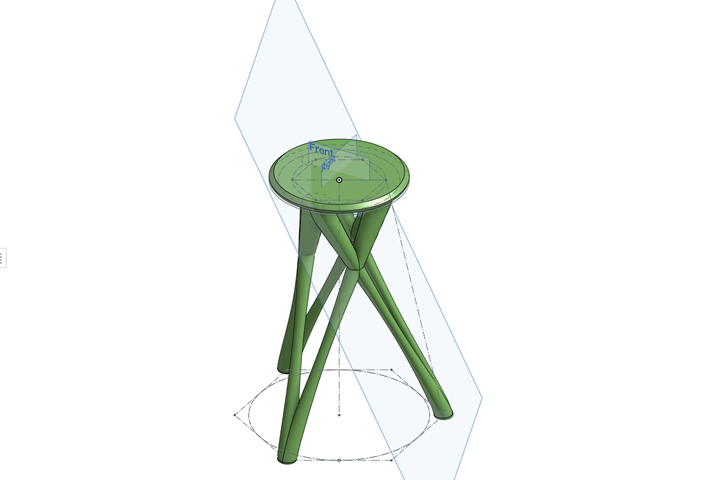

There is, of course, a lot happening behind the scenes to make this possible. Spokbee's product listings run on OnShape, a cloud-based CAD solution (now part of PTC) that allows for certain aspects of designs to be set as parametric variables. Designers can constrain the size of a ring for instance to keep its design elements looking as intended, or limit the length of a bracket arm to ensure it remains functional and within a certain printer build volume, while still granting flexibility to customers.

The Spokbee platform uses OnShape for product designs. The cloud-based software makes it easy to support parametric customizations made by customers from the shop listing, if the designer chooses to allow for this. Screenshot: Spokbee

Spokbee may provide guidance about good DFAM practices and help to ensure printability, but designers have ownership. They can alter designs and continue to make updates in real time, even after launch. And unlike free file sharing sites, creators always maintain control of their IP even while allowing adaptability through the parametric options. Designers even set their own margins; the pricing algorithm takes into account what the designer wants to make from each sale along with Spokbee’s margin, in addition to the type and amount of material needed and cost of manufacturing the product.

When an order is placed, Spokbee manages the workflow of distributing jobs to service bureaus in its network. Its manufacturing partners include broad-ranging providers like Shapeways, as well as more specialized technology providers like Nano Dimension (for PCBs and very small parts) and BigRep (for furniture and other large 3D prints). The full list of partners is not public, but covers a wide range of materials and technologies.

"We are connected with different manufacturers with various capabilities, from metal to large scale, running the gamut of the seven 3D printing technologies,” Cameron says. It will ultimately be up to designers to decide on the appropriate 3D printing method(s) for their products and any needed or desired postprocessing, all of which will be factored into the price the customer sees.

The arrangement creates complexity in the design stage, as creators need to anticipate and control for the customization range they plan to offer as well as account for the peculiarities of their chosen manufacturing process. However, off-loading production reduces the workload and skills needed to launch a new product.

“Think of the challenges of manufacturing any part or product at scale, or what it takes to make a desktop 3D printer work consistently well,” says John Hart, MIT professor and an advisor for Spokbee. “A platform such as Spokbee allows individuals and organizations to create a revenue generating product without having to invest in the hardware required to produce it.”

Spokbee could also be a powerful tool for spare parts. Rather than store excess parts indefinitely, an OEM could create a 3D printable design, load it into a storefront, and let Spokbee manage future orders on demand.

The Case for the Mass Customization Marketplace

The company sees a number of potential use cases for this solution. Large, existing companies could open Spokbee storefronts to sell accessories or customizable ranges of products like lighting or luxury goods. Influencers and makers in specialized niches like RC racing could use Spokbee to sell products originally designed for their own use. Service bureaus that are part of the manufacturing network could have Spokbee stores on their own websites, with the arrangement that they will win the work for orders made there. Spokbee itself will also sell its own products.

"We’ve made it so fast to launch products, we thought, well, why not?" Cameron says. Part of the hope for Spokbee is that removing hurdles around design and bringing products to market will lead to increased use of additive manufacturing overall.

Spokbee’s platform has many potential applications, Cameron says, from jewelry to home goods to industrial components to spare parts.

“There are hundreds of billions of dollars that could be moved into the very modest size of the 3D printing service industry through this,” Cameron says. “This isn’t going to be the overnight success. But this is going to be the beginning of a very important tool to increase the size of the 3D printing service industry, by removing the need for everybody to design in order to take advantage of 3D printing.”

“To scale additive manufacturing, we need more efficient connections between designers and production capabilities,” Hart adds. “I can see a long horizon for exciting software products and services in this space.”

Spokbee is currently working out some remaining bugs, adding service bureaus to its network and pursuing a round of fundraising. Cameron expects to launch within the OnShape app store within a few months of this writing, sometime in summer 2022.

Related Content

VulcanForms Is Forging a New Model for Large-Scale Production (and It's More Than 3D Printing)

The MIT spinout leverages proprietary high-power laser powder bed fusion alongside machining in the context of digitized, cost-effective and “maniacally focused” production.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreHow Norsk Titanium Is Scaling Up AM Production — and Employment — in New York State

New opportunities for part production via the company’s forging-like additive process are coming from the aerospace industry as well as a different sector, the semiconductor industry.

Read MoreRead Next

Angled Makes It Possible for Anyone to Launch a 3D Printed Product

The online store utilizes open capacity at its sister 3D printer farms for on-demand production with no startup costs, allowing designers to sell physical products as easily as digital ones.

Read MoreHow Tilt Hydrometer Fights Supply Chain Disruption with 3D Printing

The maker of a digital hydrometer for beer brewing keeps its supply chain and product flexible through selective laser sintering of a critical component.

Read MoreAM Brings Down the Wall Between Manufacturing and Design

In additive manufacturing, design and manufacturing blend together. They can’t be separate if AM is to realize its promise.

Read More

.jpg;width=70;height=70;mode=crop)