3D Printed Calibration Fixtures for Ultrasonic Flowmeters

Calibrating industrial flowmeters requires temporarily attaching equipment to pipes to check the flow and make adjustments. Emerson shares how 3D printed fixtures can simplify the connection and make calibration faster, easier and more accurate.

3D printing allows for greater customization of a final product, which can make it easier for manufacturers to perfectly tailor equipment to a customer’s specifications. Manufacturers of ultrasonic flowmeters, used to monitor fluid flow in industrial processes, have been using 3D printing for components of these systems for years, due to 3D printing’s higher accuracy, lower costs and other benefits. Given the importance of the accuracy of calibrating these meters, 3D printing can improve the production and accuracy of calibration fixtures as well.

Ultrasonic Flowmeter Technology and Calibration

Ultrasonic flowmeters allow for the measurement of the flow of liquids, gases or steam through pipes. The flowmeter attaches to the exterior of the pipe using clamps. The measurement device relies on a pair of transducers to send a signal from one to the other. The signal passes through the pipe (and the substances within it), bounces off the pipe interior, and travels to the other transducer. The time it takes for the signal to reach the second transducer indicates the flow rate. As a technology, a heavy duty flowmeter permits industries to assess the rate of flow without having to install devices inside the piping, while maintaining a high degree of accuracy in the measurement.

Ultrasonic flowmeters determine the volume flow by measuring the time delay in acoustic signals sent through the pipe and its contents.Source: Emerson

Maintaining accuracy in flow rate calls for regular calibration using accurate tools. Professionals use a variety of approaches to calibrate a flowmeter. In many cases, flowmeter calibration requires the use of a reference meter and the test meter to measure the flow rate of a set amount of liquid. This testing system might use a piston prover or other device to provide a steady rate of flow for measurement. Other systems rely on the measurement of the spatial shift between the signal’s connection with the transducer, which can determine the flow rate. This system does not require a change or elimination of water pressure, as it can calibrate flow rate by adjusting the distance of the signal.

3D Printing Benefits for Ultrasonic Flowmeter Calibration Fixtures

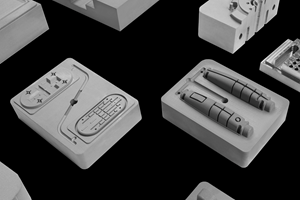

Ultrasonic flowmeters like Emerson’s Flexim line are nonintrusive and don’t need access to the pipe interior to measure the flow. But while flowmeters tend to be more permanently installed with clamps, test meters only need to be attached for the duration of calibration. Source: Emerson

3D printing offers many benefits for ultrasonic flowmeters and their calibration fixtures. The faster production, lower waste, better longevity, greater accuracy, improved customization and decreased cost makes 3D printing calibration fixtures an obvious choice.

Quicker production time

The time between the start and conclusion of production highlights the benefits of using 3D printing for parts creation. Creating a calibration fixture may require the production of multiple unique parts. 3D printing allows manufacturers to print items quickly to specification. The customization of parts can also decrease the time spent in assembly. In many cases, 3D printing decreases production time by as much as 75 percent or more.

Less waste

The use of additive manufacturing makes it easier for manufacturers to minimize waste during the production of calibration devices. Traditional manufacturing might involve producing larger quantities of each individual part, which can then be assembled in quantity. By relying on 3D printing, manufacturers can produce only what they need, when they need it. Additive manufacturing also decreases the amount of material manufacturers use for each product, which can lower overall waste.

Improved longevity

Parts fail, but the manufacturing process makes a significant difference in the failure rate. 3D printing often eliminates many of the flaws of the human manufacturing process, including mismeasurements and waste. Additive manufacturing often decreases the total mass of each component, which can lower stress on the calibration fixture and the equipment attached to it.

A different style of ultrasonic flowmeter. Meters can be installed in many configurations using various methods; 3D printed fixtures can help simplify the creation of custom attachment methods for specific situations. Source: Emerson

Higher accuracy

Calibration of flowmeters requires a great level of accuracy, and 3D printing can ensure better readings. Improper assessment of the flow rate can lead to damage to the pipes, leaking and other hazards. 3D printing ensures greater fidelity to the original design of the calibration fixture, decreasing the rate of errors and improving the accuracy of the calibration. A 3D printer also gives manufacturers the ability to test the product faster and more frequently, allowing equipment producers to focus labor efforts on the quality of the product and the accuracy of the design.

Greater customization

Industrial organizations with pipes of unusual dimensions often struggle to find components that fit their equipment. In decades past, traditional manufacturers may have refused to make certain sizes because it was not cost effective to create the mold and go through the manufacturing process for one or two possible customers. 3D printing can easily resolve the problem. A 3D printer can make minute adjustments to the design of a product, allowing for the production of parts that fit the flowmeter system and work perfectly. In addition, the customization of the calibration fixture increases the overall accuracy of the calibration.

Lower cost

Ultimately, these benefits often lead to a lower cost for production, assembly and product price for 3D printed calibration fixtures. In some cases, manufacturers of 3D components report a decrease in production costs of 50% or more. Manufacturers can produce parts for calibration fixtures in a shorter period of time, with less reliance on the supply chain and human labor. This leads to cost savings that manufacturers can use to invest in the development of improved products.

3D Printing vs. Welding or Casting

Although welding and casting are common technologies for the production and installation of flowmeters, 3D printing can make improvements on these older approaches. Welding parts to a pipe often weakens the material, leading to a higher degree of breakage and a longer time for installation. A 3D printer can customize the component for a perfect fit and faster installation. Casting or molding parts often requires the production of many pieces at once, which can slow production time. Manufacturers may be unwilling to create a mold for a product with low demand, while they could use a 3D printer to create different sizes with less effort.

As a comparison to traditional methods of manufacturing, 3D printing stands ahead of the pack. By using 3D printing, manufacturers of ultrasonic flowmeter calibration fixtures can lower their overall costs, cut manufacturing time, maintain tight adherence to the original design, minimize installation and improve the accuracy of the calibration. Industrial businesses and organizations that use ultrasonic flowmeters can benefit from the decreased stress on the equipment and the higher efficacy of each calibration. The result is a better product that helps to maintain the correct flow rate and minimize damage from improper flow.

About the Author

Izzy Rivera is the HVAC & Gas Service manager at Emerson. Rivera has been involved with ultrasonic flow measurement for 40 years, spanning the history and development of this technology. He was involved in developing the first fully integrated ultrasonic gas meter. He co-founded Flexim Americas back in 2005, which is now a part of Emerson Electric.

Related Content

In "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreComplete Speaker Lineup Announced for the 3D Printing Workshop at NPE2024: The Plastics Show

Presentations will cover 3D printing for mold tooling, material innovation, product development, bridge production and full-scale, high-volume additive manufacturing.

Read More3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.

Read MoreRead Next

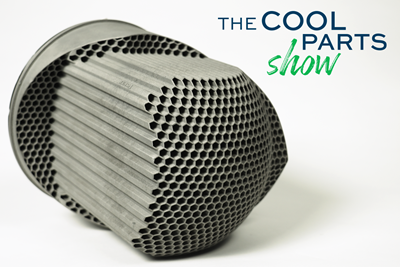

Variable Resistance Valve Trim Achieves Lead Time Reduction Through AM: The Cool Parts Show #69

Baker Hughes is realizing shorter lead times and simplified manufacturing through powder bed fusion to produce valve trims previously assembled from many machined metal parts.

Read More3D Printed Valve Part Protects Pipes by Preventing Cavitation: The Cool Parts Show #56

The Fisher Cavitrol Hex trim from Emerson divides the fluid flow into numerous parallel streams thanks to geometry made possible through additive manufacturing.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More