New Materials Support Medical-Grade Polypropylene Extrusion

PPprint’s latest portfolio of polypropylene grades support extrusion AM use for custom medical parts, like orthotics and orthopedic aids.

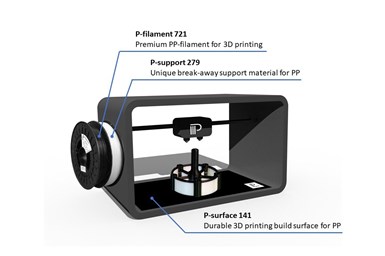

Polypropylene grades from PPprint meet the stringent material requirements for use in additively manufactured custom orthoses and orthopedic aids. Photo Credit: PPprint

While additive manufacturing’s elimination of retooling makes it attractive to assistive aid manufacturers customizing and personalizing products for individual patients, proper materials must achieve compatibility with additive manufacturing methods at high qualities before any manufacturing takes place. These materials must satisfy several chemical, biological and technical standards, with certain applications also requiring satisfaction of break resistance and flexibility standards. Other applications might call for the ability to easily clean or sterilize the material, or for suitability for skin contact.

The affordability and quality of 3D extrusion printers has made extrusion-based techniques like FDM and FFF dominant in the medical market, but established extrusion-based 3D printing materials like PLA and ABS don’t reach the required performance profile required for many medical applications. PPprint GmbH means to change matters with its polypropylene product portfolio.

Positive Points of Polypropylene

Polypropylene is one of the world's most-consumed plastics, and has already proven capable in many injection molding and extrusion applications across multiple industries — including medical. PPprint says recycling polypropylene is quick and efficient, making it attractive from a sustainability perspective, while its resistance to acids, bases, alcohol and water appeals to medical manufacturers. Several grades of polypropylene are skin-friendly and non-hazardous to health, and many grades are compatible with sterilization processes and can be cleaned manually or in a dishwasher.

Unfortunately, many polypropylene grades prove difficult to 3D print in terms of interlayer bonding, warpage, bed adhesion and reliable support materials. Solutions such as adhesive tapes or glues are not suitable for industrial applications, and turn many users away from using polypropylene. PPprint believes its product portfolio solves these issues and enables the reliable printing of high-quality polypropylene parts of any shape complexity and geometry.

PPprint is offering three unique grades of polypropylene for additive manufacturing: P-filament 721 for the main body, P-support 279 for supports and P-surface 141 for build plates. Photo Credit: PPprint

Solving Material Challenges

Successful extrusion-based printing of polypropylene requires a printed material with a low warpage and high interlayer bonding strength, a support material for overhangs and openings that can be easily removed from the finished part, and a 3D printing build surface that allows both reliable 3D printing of polypropylene parts and the non-destructive and residual-free removal of the finished part without any additional chemicals.

Building on its founders’ research experience with polyolefins, PPprint developed polypropylenes to solve these three challenges. The main product of PPprint’s portfolio is “P-filament 721,” which is available in the diameters of 1.75 mm and 2.85 mm. The filaments offer low warpage and very high interlayer bonding strength, with the “P-filament 721 natural” grade meeting DIN EN ISO 10993-5 biological safety certification requirements, which govern medical devices in contact with skin.

Next, PPprint developed its “P-surface 141” 3D printing build surface, which supports reliable and reproducible printing of polypropylene with simple, defect-free removal of 3D printed parts at elevated temperatures.

The third pillar of PPprint’s polypropylene catalog is “P-support 279,” a break-away support filament which enables the production of detailed and complex structures containing bridges, overhangs, and openings. This support material adheres very well to polypropylene printed parts as well as to “P-surface 141,” and can be easily and cleanly removed at elevated temperatures.

Polypropylene for Adaptive Aids

Adaptive aids such as orthoses or orthopedic aids enable individuals with physical injuries, mobility limitations or disabilities to live as independently as possible. These gadgets can increase a person's mobility, degree of function and capacity to execute daily tasks. Considering the variety of physical limitations that people may experience due to genetics, illness or injury, these devices must address an vast set of requirements while being adaptable to particular user-specific criteria. As a result, assistive aids must be highly customized to be effectively functional — making them prime candidates for additive manufacturing.

This 3D printed leg splint used P-filament 721 as the base, with P-support 279 as the break-away support material. The support is recyclable, promoting sustainability. Photo Credit: PPprint

One practical example of these polypropylene grades coming together is a 3D printed leg splint made from P-filament 721 and support material P-support 279. The support material provided high stiffness and low warpage while maintaining adherence to the printed polypropylene part and P-surface 141. The user could also print rafts and support structures on top of the printed part, then cleanly and easily remove the support material after heating up to 210° to 230°F (100° to 110°C). The break-away support did not require solvent or create an aqueous polymer containing waste, and still proved simple enough to recycle, promoting sustainability in several ways.

In short, extrusion-based 3D printing with polypropylene grades like those from PPprint enables unique, complex geometries that support the stabilization, immobilization, relief, guidance, or correction of different body parts and boost the healing process. With these geometries and materials, medical manufacturers can produce customized orthoses or orthopedic aids that are comfortable and effectively withstand mechanical stresses.

Related Content

Q&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

Read MoreOvercoming Challenges with 3D Printing Nitinol (and Other Oxygen-Sensitive Alloys) Through Atmospheric Control

3D printed nitinol has potential applications in dental, medical and more but oxygen pickup can make this material challenging to process. Linde shares how atmospheric monitoring and the use of special gas mixtures can help maintain the correct atmosphere for printing this shape alloy and other metals.

Read MoreCranial Implant 3D Printed From Hydroxyapatite Ceramic: The Cool Parts Show #76

Cranial implants are typically made from titanium or PEEK; in this episode of The Cool Parts Show, we look at how implants made from a bioceramic can improve osseointegration and healing.

Read MoreMicro Robot Gripper 3D Printed All at Once, No Assembly Required: The Cool Parts Show #59

Fine control over laser powder bed fusion achieves precise spacing between adjoining moving surfaces. The Cool Parts Show looks at micro 3D printing of metal for moving components made in one piece.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More