Share

Read Next

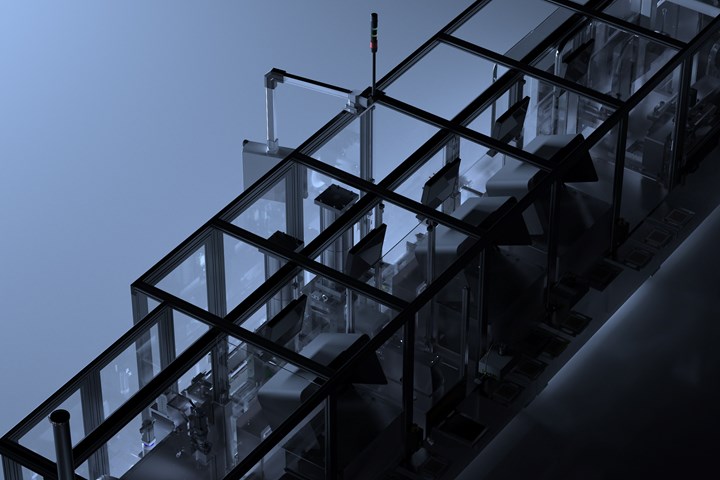

Sakuu’s Kavian platform is designed to combine multiple materials and 3D printing processes into a single part layer. This will enable production of 3D printed solid state batteries. Images courtesy Sakuu.

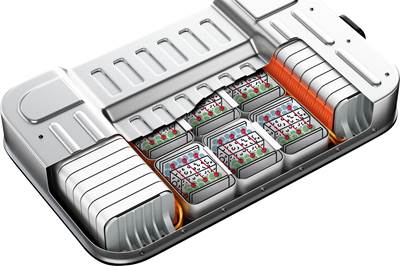

Lithium-ion batteries are the most popular type of battery for electric vehicles because of their relatively good energy density and self-discharge rates. But these batteries can have some downsides. Solid state batteries (SSBs) have a number of benefits over lithium-ion batteries and could provide a better option for powering electric vehicles. The benefits include:

- Safety. The main benefit of SSBs over lithium-ion batteries is that they use a solid electrolyte instead of a liquid electrolyte, which carries a risk of catching fire if the battery is damaged or overheated.

- Double the energy density. SSBs could have twice the energy density of lithium-ion batteries, meaning manufacturers could produce batteries that are half the size with the same energy density, or the same size with twice the energy density.

- Freedom from cooling or safety systems. Because SSBs aren’t at risk of catching fire, they don’t require the cooling and safety systems that lithium-ion batteries do. This translates to weight savings in electric vehicles.

- Greater stability. Because solid electrolytes are more stable than liquids, they have the potential to charge faster and last two to three times longer than lithium-ion batteries.

Despite the advantages, SSBs haven’t yet found widespread adoption in electric vehicles. “There's been a lot of solid state batteries designed, but they've never made it to production for various reasons, usually manufacturing difficulties,” says Dave Pederson, vice president of marketing and business development at battery technology company Sakuu. He describes a solid state battery as being like a layer cake, with a layer of solid electrolyte sandwiched between the anode and cathode. “If you try to build that up using sheets of individual materials, it's very difficult to get interfaces that work correctly, especially at the scale you need, typically 20 to 30 microns thick,” he explains. “They're very difficult to handle and it’s very difficult to make sure they touch adequately without the use of liquids.”

Additive manufacturing could provide a way to build solid state batteries that doesn’t require handling delicate sheets of materials and ensures that the layers interface properly. Sakuu was founded in 2016 with the goal of developing a multi-material 3D printing process for producing solid state batteries. Together with industry partners, including Japanese auto manufacturer Musashi Seimitsu, the company is working to advance electric vehicle capabilities with better batteries.

Solid state batteries could have a wide range of applications, from the pouch cell, prismatic cell and phone battery shown here to batteries for electric vehicles.

Multiple Materials, Multiple Processes

The challenge with 3D printing a solid state battery is that the platform has to combine different materials and 3D printing processes within a single layer. “Envision it as building a product layer by layer, using multiple deposition techniques per layer, and then assembling the layers into the final product at the end of the machine,” Pederson describes.

The printing process depends on the feature being printed — the platform, called Kavian, uses a binder jetting-type process for larger areas and material jetting for finer details. “You could say, ‘I'm going to do a layer of ceramic that's 25 microns thick, and I'll do that using a bulk deposition technique. And on top of that, I'll put a current collector that's measured in the microns of thickness. And there I'll use material jetting,’” Pederson explains.

The company says that the Kavian platform has the ability print ceramic, glass, metals, and polymer in one layer, although it couldn’t reveal the exact materials that go into the 3D printed solid state battery, including the composition of the solid electrolyte and the types of materials it’s jetting. It also wasn’t able to reveal details of its material jetting process, though it does say the machine can jet a range of materials in different forms, including powders and inks.

The biggest challenge of multimaterial 3D printing, according to Pederson, is material compatibility. “We have a large group of material scientists ensuring that the consumables, the binders and so on, that you use in the various steps along the way, and the physical materials themselves are all ultimately compatible into the final product,” he explains. This extends from printing through to sintering.

To ensure compatibility, Sakuu manufactures all of the materials used in the platform, including a proprietary ceramic powder and binder, as well as a support material called PoraLyte. This a polymer-like support material that burns away during sintering to create channels, voids and porosity. “Because a battery is just not the same density of materials all the way through, we do have to manage material porosity,” he adds.

Because it combines multiple 3D printing processes into one platform and runs them in parallel, Sakuu’s Kavian platform is designed for production.

Scaling Up

The platform is designed for production — combining all of the production processes into a single platform increases throughput. Running the processes at the same time speeds production even further. “We look at the processes that are slower than their neighbors, and we parallelize as required,” Pederson explains. “Bulk deposition is easy to scale, but maybe you have to parallelize some of the finer depositions.”

AI control will also help users scale throughput. “We're incorporating machine learning into the platform, and our goal is that the platform will be autonomous when it's done, so that at an industrial scale, you don't have technicians crawling all over them,” Pederson adds. “Our long term goal with the platforms is a lights-out type of factory where you could put the machines in and they take care of themselves. We're a ways away from getting there, but we're putting all the design elements in today to do that.”

From the Lab to the Production Floor

Sakuu has validated its 3D printing processes and materials, and is currently formatting them for a production environment. “We've proven all of the steps in the lab, and now we're in the process of connecting them in an automated fashion,” Pederson says. In the meantime, the company is printing non-battery ceramic and metal parts for some of its customers to prove out the platform, as well as some batteries, which it plans to test later this year so that it can have machines that are ready for battery production in 2023.

According to Pederson, there could be additional applications for the Sakuu platform in the electric vehicle space beyond SSBs. The platform itself is designed to be modular, with modules for each 3D printing process, as well as auxiliary processes such as material handling, quality control, drying and powder removal, so users can customize the machine based on the product it’s manufacturing. “We've even talked to people about building pieces of electric motors because of how we can assemble metals and ceramics, using ceramics as an insulator and metals as a coil,” he says.

The demand for a multiprocess, multimaterial 3D printing platform extends well beyond electric vehicles. The company sees potential applications in micro fluidics, multi-density materials, micro reactors and flow chemistry. “It does require a lot of material science,” he notes, “but it opens the possibility of building products in ways that you couldn't before or products that you couldn't envision before with this type of core technology.”

Related Content

Faster Iteration, Flexible Production: How This Inflation System OEM Wins With 3D Printing

Haltec Corp., a manufacturer of tire valves and inflation systems, finds utility in 3D printing for rapid prototyping and production of components for its modular and customizable products.

Read MoreIndyCar's 3D Printed Top Frame Increases Driver Safety

The IndyCar titanium top frame is a safety device standard to all the series' cars. The 3D printed titanium component holds the aeroscreen and protects drivers on the track.

Read MoreDaimler, OMIC Evaluate Wire-Fed DED for Moldmaking

3D printing a core and cavity on machine from Gefertec, followed by machining, allowed for a complete mold tool to be produced in three days.

Read MoreWhat Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreRead Next

Photocentric Explores How 3D Printed Battery Electrodes Could Drive Electric Vehicles Forward

Precise control of battery electrode architecture through photopolymerization opens the door to new cell geometries and lighter battery packs for EVs and more, Photocentric says.

Read MorePlastics Assembly Expert Joins Development and Production via 3D Printing

Manufacturing technology supplier Extol has always served customers who are producing polymer parts. Now, it is making some of those parts in-house through 3D printing, providing new options ranging from functional prototyping into bridge production and beyond.

Read MoreHow Additive Manufacturing is Filling Electric Vehicle Production Needs

Electric vehicles are reshaping transportation, but they are also changing vehicle production. Electrification brings a blank slate to the manufacturing process, providing inroads for additive manufacturing to potentially fill production needs.

Read More