Metal AM: Is Welding the Way In?

Optomec’s machine tool for metal 3D printing is also an accessible system for automated welding. The embrace of one use of this machine might lead to increasing exploration of the other.

Share

Read Next

Additive manufacturing as a means of making metal parts is a new possibility for many production facilities. Meanwhile, welding is a metalworking operation that is commonplace, well-established and widely employed.

Yet aren’t these overlapping practices?

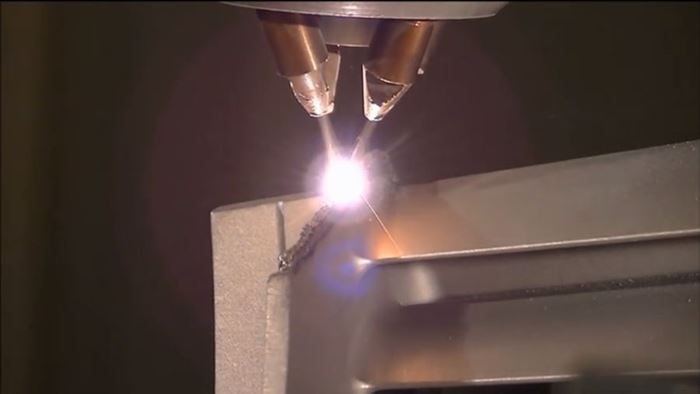

In the case of metal AM via direct material deposition, they certainly are. Welding consists of adding a layer of molten metal to the work, often for repair of an existing part. Direct-deposition AM also consists of adding a layer of molten metal to the work—and then another layer and another atop that—in order to build up a three-dimensional form or feature. A direct-deposition metal AM system therefore could be used for some welding applications, and if the system is inexpensive enough, then this might even be its primary use and justification.

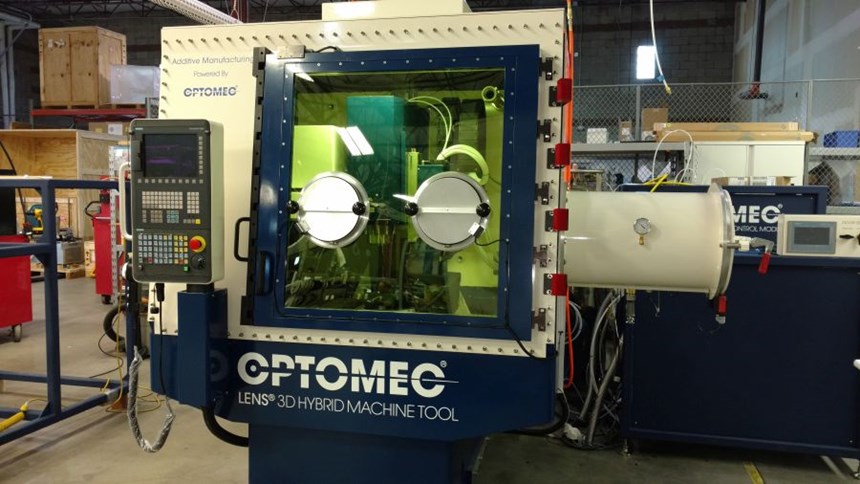

David Ramahi, president and CEO of Optomec, says his company is becoming increasingly aware of the importance of this potential use of its metal-deposition equipment. Last year, the company introduced a standard product consisting of its Laser Engineered Net Shaping (LENS) metal AM technology integrated into a standard vertical machining center. The result is a metal 3D-printing system available for about $250,000, he says, with milling capability also available in this same machine for about 10 percent more. But at that relatively low price, says Ramahi, 3D printing does not necessarily have to be the point of the machine. Where the purpose of welding is repair, or resurfacing parts to put them back into service, the machine could offer a solution for that need.

Skilled welders are becoming difficult to find, he notes. As is the case with various industrial trades, welders today are nearing retirement in greater numbers than new people are entering the field. Therefore, while replacing manual welding in some cases with automated welding on a CNC machine tool might be a leap for many facilities, it is a leap that can address an otherwise challenging personnel problem. Indeed, given that these facilities likely already have CNC machining centers, and given that widely-used software including Mastercam and Powermill has already been adapted to program the LENS machine, this choice might represent the leap into automated welding that is easiest for them to make. Along the way, it might also extend the range of repairs welding can peform, because—different from MIG or TIG welding—LENS is a targeted deposition process allowing for repair of thin walls and other delicate features with minimal heat effect.

The annual value of welding overall in industrial production is about $20 billion, Ramahi says. Welding for repair represents a share of that, but it is a share he beleives is on par with welding for joining. Thus, the annual value of repair-related welding is far greater than the current annual value of industrial 3D printing. But in the scenario he foresees, the use of one might lead to increased use of the other. Welding might be part of the way for AM to find its applications and advance into its ultimate promise. For the facility that has justified a metal AM machine simply for welding, using that same machine to 3D print features onto existing parts, or 3D print complete parts, represents a natural next step that the machine is just waiting for that user to take.

Related Content

3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreDMG MORI: Build Plate “Pucks” Cut Postprocessing Time by 80%

For spinal implants and other small 3D printed parts made through laser powder bed fusion, separate clampable units resting within the build plate provide for easy transfer to a CNC lathe.

Read MoreWith Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MoreRead Next

Bike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More