Latest Issue of AM: Seeing is Believing

A photo essay documents the types of parts that are possible with an additive production process. The parts come from a medical manufacturing company that is now using additive manufacturing to create implants and instruments that would have been impossible or impractical to create by any other means.

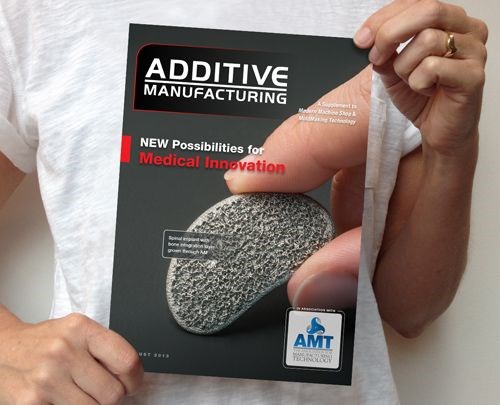

Our latest issue of Additive Manufacturing includes a photo essay documenting the types of parts that are possible with an additive production process. All of the parts shown come from IMDS, a medical manufacturing company that is now using direct metal laser sintering to make implants and instruments that would have been impossible or impractical to create with any process other than additive manufacturing. Also in this issue, another article describes a tooling and product development company’s comparable advance from applying 3D printing for prototyping into applying it for the creation of useful parts and tooling.

Additive Manufacturing is a supplement to Modern Machine Shop and MoldMaking Technology magazines. Subscribers to the print version of the supplement receive it with their copy of either magazine, but you can also read the latest issue right now in its electronic version.

(Thank you to Gardner Business Media’s Laurie Dugan and Jeff Norgord, who took photos for the photo essay in this issue. Because Laurie held the part on the cover, her right hand appears twice in the photo above.)

Related Content

-

Machine Tool Drawbar Made With Additive Manufacturing Saves DMG MORI 90% Lead Time and 67% CO2 Emission

A new production process for the multimetal drawbar replaces an outsourced plating step with directed energy deposition, performing this DED along with roughing, finishing and grinding on a single machine.

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

-

Additive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.