3D-Printed "Smart" Shaft Introduces AI Possibilities

VTT Technical Research Centre introduces a process for 3D printing a metal shaft with embedded sensors.

Share

Read Next

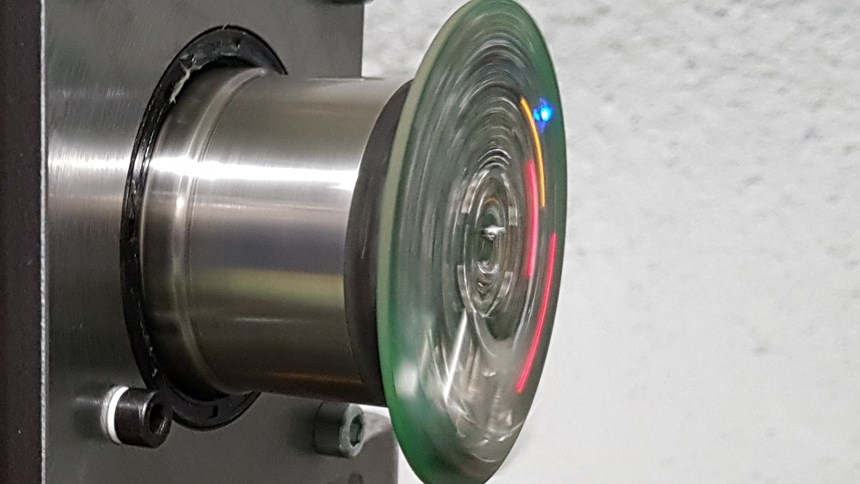

VTT Technical Research Centre of Finland has 3D-printed a “smart” shaft, using a process which the company says is a step toward artificial intelligence (AI) development. The overall process management chain includes 3D printing, sensor technology, wireless data transfer and condition monitoring in the same package. The company’s methods are designed to enable the creation of new business models and to provide a competitive edge in developing AI.

According to the company, the research focus was the creation of a way for sensors to form a functional part of a 3D-printed metal structure. The resulting methods enable a range of sensors or smart identifications to be added to 3D-printed metal parts during manufacture. The sensors can track the performance and condition of machines or devices, or verify the authenticity of the parts.

During the manufacturing phase, an accelerometer and wiring are embedded into a 3D-printed metal shaft for a friction bearing. Electronics allowing wireless communication are installed onto the bearing allowing wireless data to be directly and rapidly transferred from the component to the cloud. This could lead to developments in artificial intelligence, the company says.

The method provides the designer with a large degree of freedom compared to traditional manufacturing methods, the company says, as it enables sensors to provide up-to-date information such as maintenance status without breaks in production.

Possible applications include industrial manufacturing, energy, mining and transport. Embedded sensors are designed for demanding conditions, the company says, because the sensors and wiring are protected inside the component, and normal functioning is unimpeded by extraneous wiring on the surfaces of structures.

Related Content

-

Hexagon Invests in Divergent’s Autonomous, Sustainable Manufacturing

The Divergent Adaptive Production System (DAPS) is a fully integrated software and hardware solution, creating a complete modular digital factory that combines AI-optimized generative design software, additive manufacturing and automated assembly to build lightweight automotive parts and frames.

-

Carnegie Mellon Helps Industry, Students Prepare for a Manufacturing Future with AM and AI

Work underway at the university’s Next Manufacturing Center and Manufacturing Futures Institute is helping industrial additive manufacturers achieve success today, while applying artificial intelligence, surrogate modeling and more to solve the problems of the future.

-

Spatter, Surrogate Modeling and More Advanced Manufacturing Research Happening at Carnegie Mellon University: AM Radio #53

In this trip report, we discuss research at the Manufacturing Futures Institute and Next Manufacturing Center, both under CMU’s umbrella, to advance industry with robotics, AI and additive manufacturing.