Hybrid Additive Manufacturing Machine Tools Continue to Make Gains (Includes Video)

The hybrid machine tool is an idea that continues to advance. Two important developments of recent years expand the possibilities for this platform.

The hybrid CNC machine tool is an idea that continues to advance.

This is worth seeing. That term — hybrid — refers to a machine tool that offers additive manufacturing capability in addition to the machine tool’s normal work of machining within a machine able to mix both operations in a single cycle. As a working concept, the idea is a decade old. And while applications are not so widespread that hybrid machines are found in typical machining job shops, applications are numerous enough to offer an expanding market that continues to be served. The hybrid machine tool is, in one sense, a niche technology. In another sense, it is something more, because there is a diversity of niches in which the technology offers promise.

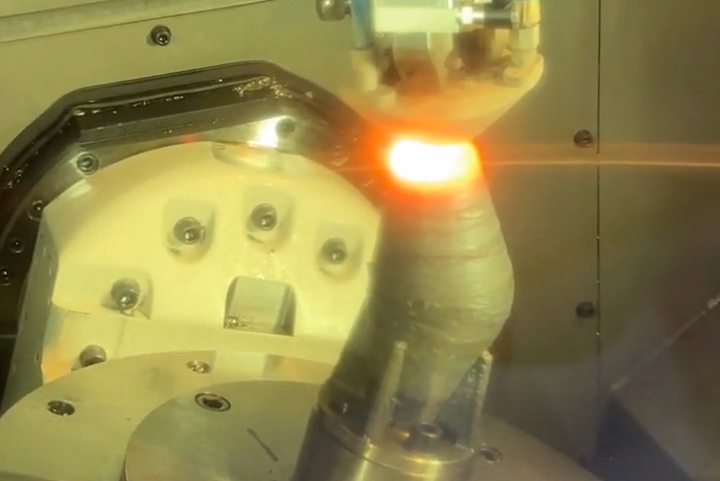

Metal 3D printing operation on a Mazak machining center. This shot is a still from the video below on the hypersonic missile nosecone.

At a distance, the hybrid machine tool seems just provocatively useful. The machine offers the chance to begin with an empty work zone, and not only create a part the way a 3D printer can, but also machine it to its required tolerances as part of the same cycle. Considered more closely, the hybrid model poses some challenges. But the matter of when to use a hybrid and what it can do is not at an end. In the last several years, I have seen at least two major developments that seem to me to have opened wider the extent of how useful a hybrid machine can be.

First, the limitations. The hybrid idea inherently means one machine carries the capabilities of two, but puts only one set of capabilities to work in any moment. The potential for process imbalance thus means the machine, while versatile, is not necessarily efficient for a given application. A part made complete using metal 3D printing and machining might require, say, only one-third as much machining time as the 3D printing. This being the case, it is possible that two or three single-purpose AM machines used in tandem with one single-purpose CNC machine tool might provide a faster and cheaper solution if the use is recurring production.

This limitation is why cladding and repair are two applications in which hybrid often is an attractive choice. Cladding does not involve 3D printing a complete form that also needs machining, but instead involves adding a layer of material to a surface ahead of machining. Additive and machining time are balanced enough that one is not kept waiting long within the shared cycle. Something similar is true of using a hybrid machine to repair a valuable tool or part: Restoring the worn or damaged feature calls on both 3D printing and machining, using them both nearly enough in balance and in tandem that the hybrid machine is far more capable and efficient than trying to perform the same repair through multiple separate operations and setups.

Another limitation, or at least a consideration, is this: Hybrid machine tools performing 3D printing generally do so through laser metal deposition, meaning the machine shop adding this type of machine must add laser melting to its mix, likely an unfamiliar capability. Some hybrid machines also employ powder metal as the material stock, which, for the typical shop, is apt to be an unfamiliar material choice with new safety considerations to accommodate. Yet this latter detail points to one of the developments of the past several years that I see bolstering hybrid’s promise. Namely, wire-fed deposition systems arrived as an additional option. The laser is still there as a new system to learn, but spools of wire are a much easier form of metal stock to handle and manage.

Here is the other major development that I see helping hybrid: The COVID pandemic and its effects on logistics and supply turned seemingly all manufacturers’ attention to their supply chains. Steps such as casting or assembly might add considerable lead time, complexity or supplier vulnerability to a given product’s process, and the impact of this is now seen and questioned to a greater extent than it was just a few years ago. A hybrid machine can overcome casting by making the part from scratch; it can overcome assembly by allowing machining to generate precise internal features of a complex form as the part is being built. Where quantities are low enough, the chance to bypass casting or assembly in this way is potentially valuable enough to overlook any cycle time inefficiency in the machine that can deliver this simplified, responsive, on-demand part making.

And this is where we are now. Hybrid is an option for cladding and repair, and we should watch for its application to expand as an option for complete parts as a workaround for steps that might otherwise involve time or complexity. The two major developments I cite are interrelated, since we should not discount the ease and safety of material use as a factor aiding adoption as a supply chain solution. An extreme case: The Navy warship USS Bataan now carries a hybrid machining center with wire feedstock as a method of manufacturing replacement parts as needed while the ship is at sea.

Learn more about various hybrid machine tools in the playlist of related video below.

Related Content

New Equipment, Additive Manufacturing for Casting Replacement and AM's Next Phase at IMTS 2024: AM Radio #54

Additive manufacturing’s presence at IMTS – The International Manufacturing Technology Show revealed trends in technology as well as how 3D printing is being applied today and where it will be tomorrow. Peter Zelinski and I share observations from the show on this episode of AM Radio.

Read MoreVideo: For 3D Printed Aircraft Structure, Machining Aids Fatigue Strength

Machining is a valuable complement to directed energy deposition, says Big Metal Additive. Topology-optimized aircraft parts illustrate the improvement in part performance from machining as the part is being built.

Read MoreJuggerBot 3D Chooses Research Partners for Air Force Large-Format Hybrid Additive Manufacturing Project

Oak Ridge National Laboratory and Mississippi State University’s Advanced Composite Institute have been selected to assist in the research and technical development of production workflows using thermoplastic and thermoset deposition.

Read MoreNicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

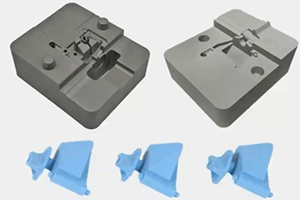

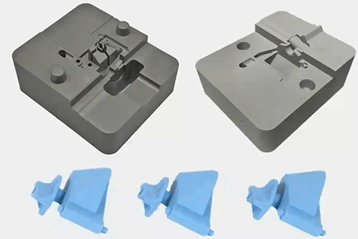

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreRead Next

Nicolet Plastics Succeeds Using Mantle's Hybrid Metal 3D Printing Method for Mold Tooling

A recent webinar explores Nicolet Plastics’ success using Trueshape Technology, Mantle’s approach to print injection mold tooling. The current challenges this technology addresses and alleviates in additive manufacturing confirms this method is effectively reducing lead times and cost constraints, while producing better inserts.

Read MoreLarge-Format “Cold” 3D Printing With Polypropylene and Polyethylene

Israeli startup Largix has developed a production solution that can 3D print PP and PE without melting them. Its first test? Custom tanks for chemical storage.

Read MoreWorld’s Largest Metal 3D Printer Seen at Ingersoll Grand Opening Event

Maker of large additive and subtractive machines adds capacity in Rockford, Illinois.

Read More