How Aggressive EV Timelines Point to AM

Electric vehicle sales are expected to grow significantly in the next decade. Additive manufacturing can help automakers fill their production needs.

Electric vehicles (EV) are here to stay. Looking at the numbers, they’ll do more than just stay. Consider these statistics and projections:

- Q1 2022 saw electric and hybrid models accounting for 40% of new car sales in France, compared to 38.3% for gasoline models. (Plateforme de la Filière Automobile (2022), Le marché automobile français mars 2022)

- In the next seven years, approximately 350 new EV models are expected to hit the automotive market worldwide. (IEA (2021), Global EV Outlook 2021)

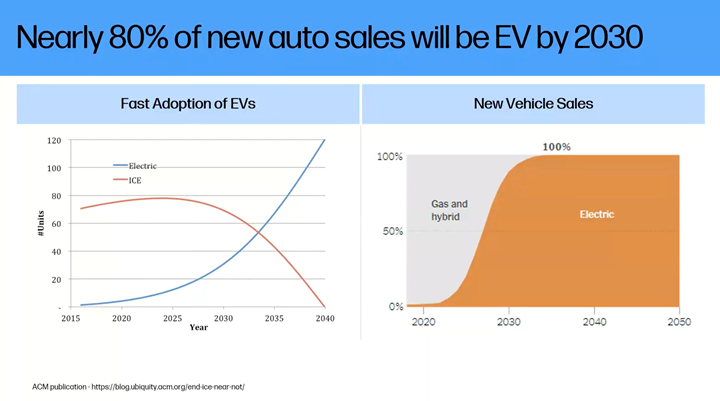

- By 2030, almost 80% of all new car sales will be EV. (Association for Computing Machinery ACM (2017), The End of ICE is Near – or Not?)

- These projections may see some influx due to the 2022 Inflation Reduction Act, which impacts the tax credit for new electric vehicles with final assembly in North America and pre-owned consumer and commercial clean vehicles. (U.S. Department of the Treasury (2022), Treasury Releases Initial Information on Electric Vehicle Tax Credit Under Newly Enacted Inflation Reduction Act)

According to the Association for Computing Machinery, EV sales will make up almost 80% of new auto sales by 2030. Note that this percentage represents fully electric vehicles. Both gas and hybrid vehicles will see a decline. Photo Credit: ACM

What role does additive manufacturing play in this progression? Two different sets of presenters recently explored this question in presentations given live (and still viewable on demand) on the Additive Manufacturing website. Alex Stern, manufacturing platform strategy lead with Autodesk, and Matteo Barale, chief product officer with PixMoving, gave a talk titled, “3D Printing for Electric Vehicles: Discovering Design Freedom and Mass Customization from the Electrification Revolution,” while HP solutions architect Aaron DeLong and 3D application engineer Wes Kramer, along with Wagon Wills, chief engineer of Gonzalez, gave a talk titled, “3D Printing for Electric Vehicles: Addressing Accelerated EV Timelines with Additive Manufacturing.” This article captures some of the takeaways of their presentations.

AM’s Impact on EV Production

For any automaker, especially those with concepts, tooling and production lines established for vehicles with internal combustion engines, these projections represent an aggressive timeline that demands accelerated product development cycles to meet it. This is just in time to face the added crunch of global supply chain issues already impacting present day automotive inventory.

This is where additive manufacturing can make an impact. With additive manufacturing’s inherent digital scope, automakers can work through concepts and renderings, but most important, they can work through tangible iterations.

“We can do them with engineering materials, we can really align to those material specifications,” says DeLong. “We can use tools like FEA and CFD to predict on the additive side what we’re going to get in production, from the injection molding. If we understand our additive material sets, we can predict whether the failure mode of the additive piece aligns with the failure mode of the injection molded piece and then predict what the injection molded piece is going to do.”’

DeLong further highlights AM’s impact through several air flow examples, including redesigning a flow splitter to optimize the cooling of a scalable EV battery platform. The solution he describes cut design time by 50% and reduced pressure drop by 47% through topology optimization and an additively manufactured part.

Both optimized parts and reduced production time will have an impact on an EV manufacturer’s bottom line, which is necessary and pragmatic, but EV’s potential — and AM’s role — also goes beyond practical concerns. Stern and Barale’s presentation makes it clear that if the future of automotive is electric, then the future of electric is boundless passenger experience.

Rethinking the Passenger Experience

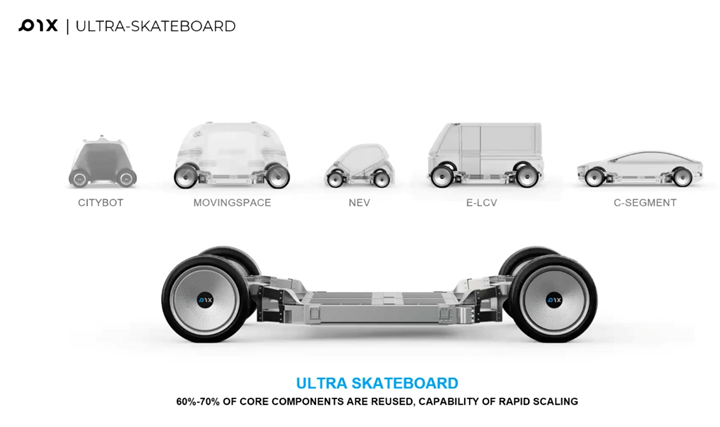

EVs are typically built upon a flat platform called a skateboard chassis that houses the batteries and motor. This foundation is essentially a blank slate for designers.

Stern explains that the electric drive train is heading toward standardization, but that does not mean all electric vehicles will look the same or even meet the same needs.

“The beauty of this is, of course, cost, high quality, everything that comes with standardization and mass production, but also this is relatively modular,” says Stern. “You can slightly alter this platform architecture and build different types of vehicles on top.”

Imagine then, a people carrier and a sedan utilizing essentially the same platform. This is easier to do with EV than conventional automotive, according to Stern, as electric vehicles face fewer packaging issues and the overall design is less engineering driven.

PixMoving’s Ultra Skateboard chassis is an example of how electric vehicles open the door for design freedom and optimized passenger experience. Photo Credit: PixMoving

EV and Autonomous Driving

Although the precipice for widespread autonomous driving is not as close as that for widespread electric vehicles, forward thinking automakers will see the potential crossover in design freedom when they consider all the things a driver can do in a car when they don’t have to drive. Stern compared the future driver’s seat to a business class seat on a plane, and the vehicle to a smartphone on wheels. Conventional design does not address a driver who might be streaming videos, socializing or even sleeping in the vehicle.

With so much interior customization potential, Stern predicts high volume manufacturing may take a backseat to small batch production when it comes to autonomous driving EVs.

Small batch production will require a different manufacturing environment, one PixMoving has already established. Barale describes the environment as a flexible factory comprised of automation and 3D printing technology that has a smaller real estate footprint and less pollution than a conventional automotive assembly line. One perk of this factory style is its potential for distributed manufacturing, an area in which additive has found success. Stern explains, too, that these smaller, cleaner factories are easier to integrate into an urban setting, allowing vehicles to be made closer to where customers live, curtailing possible supply chain complications.

For more on additive manufacturing and electric vehicles, including links to the presentations referenced above, visit gbm.media/am4ev.

Related Content

What Holds AM Back in Automotive Production? GM Additive Lead Describes Advances Needed

“If AM were cheaper, we would be doing more of it,” says GM’s Paul Wolcott. Various important factors relate to cost. However, the driving factor affecting cost is speed.

Read MoreSeurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read More8 Cool Parts From Formnext 2024: The Cool Parts Show #78

End-use parts found at Formnext this year address various aspects of additive's advance, notably AM winning on cost against established processes.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More