Digital Metal Leverages Powder Expertise into Binder-Jetting System, Now for Sale

Digital Metal, a Höganäs Group company, now offers its own additive manufacturing machine, the DM P2500 high-precision binder-jetting metal 3D printer.

With the Höganäs Group’s vast company knowledge of metal powders and the sintering process, getting into 3D printing was a good fit, says Alexander Sakratidis, sales manager for the group’s recently formed Digital Metal company. Höganäs, based in Sweden, began developing its metal binder-jetting technology in 2012 and started offering the process as a service in 2013. Now, Digital Metal is launching a binder jetting 3D printer for sale to external customers intended for the high-volume production of small, complex parts.

The knowledge of powdered metals and sintering Sakratidis mentions predates involvement in additive manufacturing. For decades, Höganäs has been a manufacturer of metal powders for more conventional processes such as press sintering and thermal surfacing, commonly used in the automotive industry. Today it also provides material for laser sintering processes, and is leveraging its materials expertise in the metal 3D printing realm.

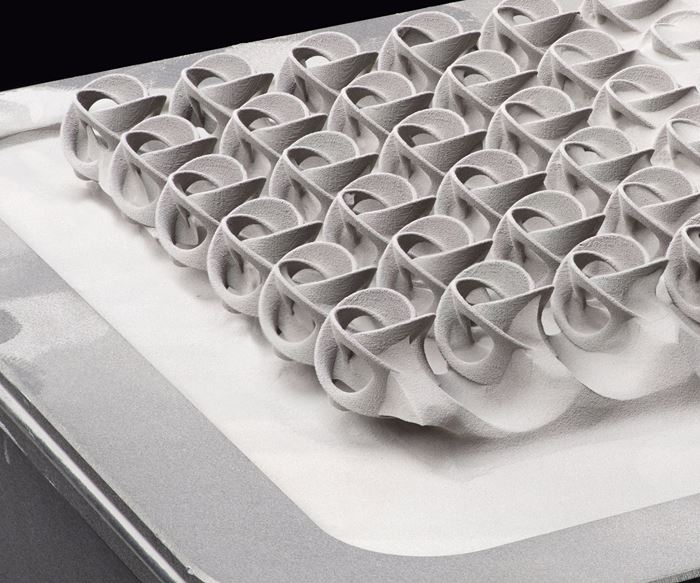

Digital Metal’s newly launched additive system is the DM P2500, which uses a binder-jetting process to build parts. An arm inside the machine spreads a layer of metal powder 0.042-mm thick, and then a binder is precisely jetted according to the part's geometry. Another layer of powder is spread over top, and the process continues until the part is complete. Following printing, the entire build box is removed from the system and loose powder is blown away with compressed air in a controlled environment. Finally, parts are placed in a sintering furnace to bond the metal and burn away the binder.

Benefits of Binder Jetting

There are several advantages to Digital Metal’s binder jetting system over other additive technologies, Sakratidis says. Broadly, it offers “better resolution, higher productivity, and can do smaller and more complex details,” he says. Key markets for its service business currently include industrial applications, dental and medical devices, aerospace components, and luxury applications.

In part production, the technology is accurate and repeatable, enabling it to make very small precise parts at a resolution of 35 microns. The sintering process results in an average surface roughness of Ra 6.0 micron, fine enough for many end-use parts and features such as internal channels without further processing. Nozzles are a good example of a component that can benefit from this; since the surface roughness is so fine, it is possible to 3D-print the entire nozzle instead of assembling it from multiple components, Sakratidis says. Sandblasting and polishing can further enhance the surface finish when necessary.

The accuracy of the system plus its lack of need for sacrificial support structures helps to keep postprocessing to a minimum. “The powder in the box supports the components, so we have no support structure that needs to be removed,” Sakratidis says. This also makes it possible to stack multiple layers of parts on top of each other in the build box for greater productivity. Very fine accuracy of 0.001 mm in the moving parts of the machine also enables the repeatability necessary for serial production.

The ability to confidently recycle metal powder is an additional benefit. Because only the bonded powder that forms the parts is subjected to the heat of the sintering furnace, the leftover loose powder can be recycled without fear of degradation. Three materials are available thus far. Digital Metal offers two types of stainless steel, acid-resistant 316L and hard, brittle 17-4PH, as well as Ti6Al4V. It is in the process of verifying other materials, and more will be available in the future. Silver and gold are in particular demand, as the binder jetting technology is well-suited for jewelry manufacturing.

Metals, Services, Machines

Digital Metal continues to offer metal binder jetting services to its customers using its in-house binder jetting system, and it has a number of serial customers who make use of this service. The largest of these orders 30,000 parts yearly, though smaller batches of 3,000 to 3,500 parts are more common, Sakratidis says. One of its customers includes a Swiss watchmaker, Montfort Watches, that uses binder-jetted stainless steel dials in its watches, for example.

However, customers can now purchase their own Digital Metal binder jetting machine: the DM P2500, offering a build volume of 2,500 cm3 and typical build speed of 100 cm3/hr. Digital Metal does not provide the necessary sintering furnaces, but will recommend appropriate models.

“There is huge potential in 3D printing, but the hurdle is to get the industrial designers to think 3D printing…so they design for optimal function instead of designing for current production capabilities.”

So far two Digital Metal printers have been sold. One was purchased by an undisclosed design company for serial production, while the second was recently installed at CETIM, France’s institute for mechanical engineering.

Along with continuing to develop materials and selling the binder jetting system, Digital metal plans to begin tackling the automation of the system. Future developments will include increasing printing speed, and the integration of robots to load and unload build boxes from the machine, enabling the system to run 24/7. "3D printing is still a lot of manual work," Sakratidis says. Alleviating some of that work will help boost productivity to better enable serial manufacturing.

Designs that take advantage of binder jetting AM will be another area of future growth.

“There is huge potential in 3D printing,” Sakratidis says, “but the hurdle is to get the industrial designers to think 3D printing, instead of conventional manufacturing, so they design for optimal function instead of designing for current production capabilities. You can make a lot of components more efficient in that way—lighter, faster, simply more optimal.”

Related Content

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreRead Next

3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read More

.jpg;width=70;height=70;mode=crop)