Freemelt Offers an Open-Source Toolbox for Material Development

Swedish startup Freemelt believes collaboration will be a way forward for metal additive manufacturing. Its Freemelt One electron beam melting system for R&D supports this open-source philosophy.

Where does the future of additive manufacturing (AM) lie? For Freemelt, the future of AM is in materials, an area of innovation that will drive future applications for the technology. But getting to that future also requires something else: collaboration.

“Even though metal 3D printing has been successful, we think it can be even more successful because we have only scratched the surface when it comes to materials,” says Patrik Ohldin, managing director of the company. “AM needs tools that support the development of materials. It was obvious to us that a ‘toolbox’ suitable for this was needed, but that no such equipment was available.”

Freemelt therefore has developed a “toolbox” for this purpose—the Freemelt One, an electron beam melting (EBM) system that is designed specifically for materials R&D. This machine, Ohldin says, is a manifestation of the company’s philosophy that combines hardware and software capabilities with open-source parameters and support for collaboration. Freemelt sees all of these as critical to the advance of additive manufacturing.

An R&D Toolbox

Based in Sweden, Freemelt is a startup company just over one year old. However, its founders together have more than 50 years’ experience in additive manufacturing, most of it with Arcam, the EBM equipment supplier now part of GE. Ohldin himself spent 12 years in sales with Arcam. Having deep familiarity with the EBM process, Freemelt’s founders had no doubts about the capabilities or promise of the technology; the gap that they saw, instead, was a limited material selection for the process and no good tools for proving out new ones.

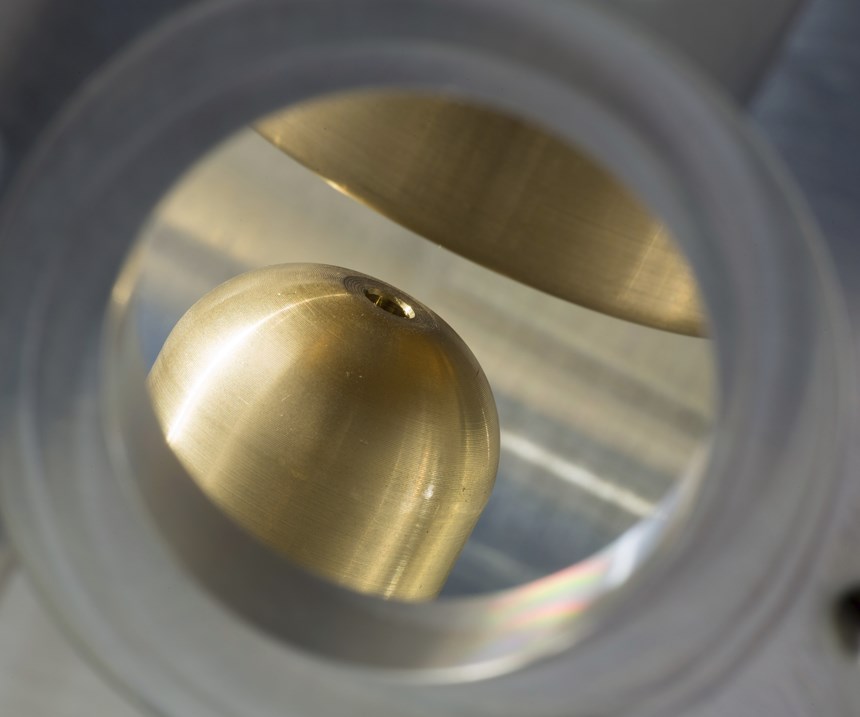

Thus, they created the Freemelt One. Where the build volumes of production systems have increasingly expanded, allowing for larger parts or greater numbers in a single batch, the goal in R&D work is rather to perform many short builds in a systematic and efficient way, Ohldin says. To support this goal, the Freemelt One has a small build envelope, just large enough to manufacture test coupons and tensile bars. The company’s motto is “All you need is a cup”—meaning all that is necessary to fill its machine is a (metric) cup of metal powder. New powders are often expensive, so a small build volume enables affordable as well as fast testing. As an added benefit, the printer’s compact build envelope makes the manual cleaning process faster when changing between materials.

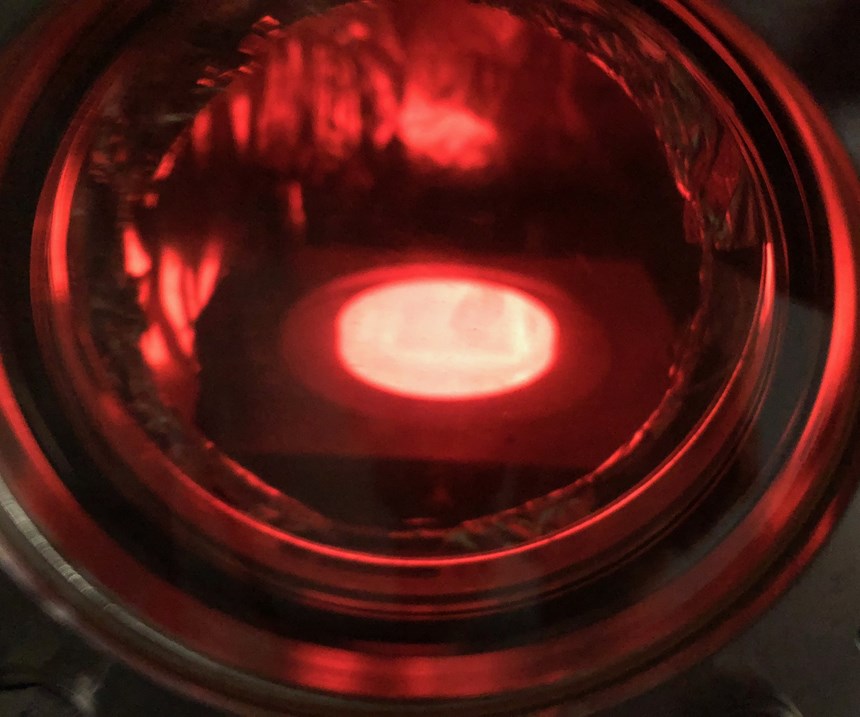

The machine is also powerful enough to support experimentation with a range of materials, offering a 6-kW electron beam and supporting operating temperatures as high as 1,200°C. Fully open machine architecture and software enables users to modify parameters such as electron beam spot size, layer thickness and more, all without restriction. The printer accommodates auxiliary equipment for R&D such as spectrometers, cameras and temperature measuring systems via its built-in ports, thereby maintaining the vacuum environment inside the build chamber. “Finding out what’s going on inside your process is key to determine whether it works or not, and why,” Ohldin says. The goal is for users to determine whether a given material will work for EBM, and when it does, to develop the process parameters that will achieve the desired properties.

Enabling Collaboration

The first Freemelt One system is expected to be delivered by early 2019. Although universities and research institutes will likely make up a significant portion of users, the company also anticipates the 3D printer being used by powder manufacturers and large industrial companies performing their own internal materials research.

What discoveries might these users make? Ohldin sees several particularly promising opportunities for electron beam melting materials in the near future. One is nonweldable, crack-prone materials that could be beneficial for high-temperature applications such as aerospace engines. Another is refractory materials that require high processing temperatures. He also notes an increasing interest from additive manufacturers in copper—a material that offers high conductivity and good thermal transfer, but is very reactive to oxygen. The vacuum build chamber of the Freemelt One offers a clean, productive environment to experiment with this reactive material.

“We can’t do it ourselves… More hands, more minds—that is the future.”

The material advances that may come with this system are largely up to customers, but Freemelt is encouraging an open-source environment around its equipment, seeing mass collaboration as key to driving metal AM forward. Customers will have the ability to opt-in to a community of fellow users to share experiences and insights. How much these community members choose to share is up to them, but the company sees collaboration and cooperation as key to accelerating materials development for additive manufacturing.

“Many times when it comes to materials, the users know more than we do,” Ohldin says. “We can’t do it ourselves. That is why we have this open-source strategy. More hands, more minds—that is the future.”

Related Content

Video: What Is Electron Beam Melting (EBM)?

Electron beam melting is the higher-energy metal 3D printing process offering advantages when it comes to productivity and thermal stresses. Here is an introduction to EBM.

Read MoreVBN Components Offers High-Performance Materials Development as a Service

Formnext 2023: VBN Components is exploring new possibilities in metal materials development, including promising prospects with hard metals and refractories.

Read MoreSciaky Manufactures Critical EBAM Component for Intuitive Machines’ Moon Landing

The Sciaky engine component was the upper section of the IM-1 lander’s main engine nozzle, which provided the main source of thrust for descent in the February 2024 mission to the Moon.

Read MoreProduction AM Demands Process and Procedures — More Machines Will Come Later

Arch Additive has transitioned to full production of implants made through electron beam melting. The transition has involved practices and personnel, not equipment. As customer products win approval and go to market, here are 5 operational moves the AM implant manufacturer has made.

Read MoreRead Next

Profilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read MoreBike Manufacturer Uses Additive Manufacturing to Create Lighter, More Complex, Customized Parts

Titanium bike frame manufacturer Hanglun Technology mixes precision casting with 3D printing to create bikes that offer increased speed and reduced turbulence during long-distance rides, offering a smoother, faster and more efficient cycling experience.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More

.jpg;width=70;height=70;mode=crop)