Iten Industries will be celebrating 100 years in business in 2022. Pultrusion, injection molding and other conventional manufacturing processes have brought the company this far; now, 3D printing will help drive it forward into the next century.

“What else can we make for you?”

The question is a simple one, but it aptly sums up the attitude toward winning new work and new customers at Iten Industries. The 99-year-old company produces composites and laminates, in addition to cutting and forming these material through pultrusion, stamping, machining, molding and more. It creates its own tooling through an in-house tooling shop and runs plastic production on its own injection molding presses. Increasingly, the company is taking on product development for plastic parts, with the ultimate goal of winning the work to provide the tools that make the parts. With any job that does come, at whatever level, Iten asks the question: What else can we make for this product or customer? In many cases, it is possible to take on additional production parts (often simplifying the customer’s work) by tapping into the variety of resources at the company’s disposal.

Yet despite all the capacity and expertise spread across Iten’s three plants in Ashtabula, Ohio, until recently something was lacking. Product development was not as fast or easy as it could have been, and while Iten has ways of creating more affordable mold tooling through a combination of stock bases and custom inserts, there were still cases where the cost couldn’t be justified for low runs of plastic parts. The result was that the company was losing out on some “what else” work, and falling short on pursuing new markets and opportunities.

Now the company is on its way to filling that gap. With one large-format industrial 3D printer already installed and another on the way, Iten Industries has one more way to serve its customers as well as a pathway into new applications.

Imagineering in 3D Printed Plastic

With Iten Industries approaching one century in operation in 2022, company leadership recently began to reflect on how to ensure the business’s continued advance. “Our experienced toolmakers and existing equipment get us there 80% of the time,” says Ron Emery, director of business development. “But we had to shift to think about the future. If we want to continue to grow, what technologies do we need?”

Iten Industries occupies three facilities in Ashtabula, Ohio. The new Imagineering Center is colocated in this building which also houses the tool room and other subtractive manufacturing capacity.

Part of the reason to bring 3D printing in house is to help capture more injection molding work, thanks to the design iteration and cost savings possible with 3D printed prototypes.

3D printing was a natural answer, both for its usefulness as a means of accelerating product development as well as a way of making those short-run plastic parts that the company was not yet well-equipped to handle. Emery also saw the long-term potential that 3D printing might have to allow the company to make bridge production runs of parts while simultaneously building the mold, and to advance into new industries and business opportunities. Polymer 3D printing could also be a catalyst for partnerships with startups and inventors lacking the capital for a full injection molding setup.

In 2020, Iten Industries established what it calls the “Imagineering Center” in one of its Ashtabula facilities. The name comes from the company’s tagline: “‘Imagineering’ with plastic,” Emery says. While this concept applies broadly to the company’s work, this space is dedicated to its newest capacity in additive manufacturing.

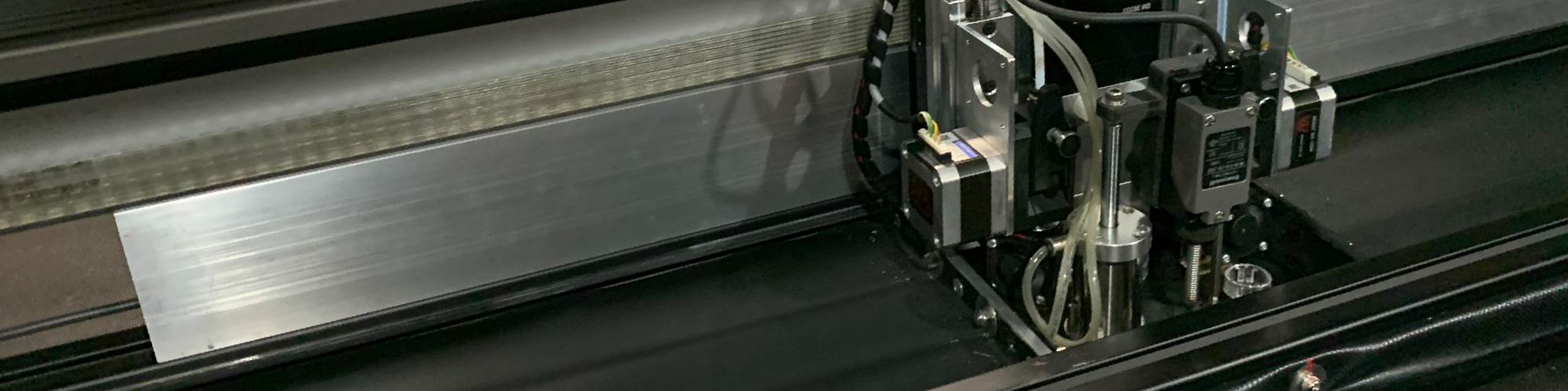

The Imagineering Center is so far occupied by a small desktop printer (left) and the Juggerbot 3D Tradesman Series F3-32, first of its kind to be sold.

In March 2021, Iten took delivery of its first 3D printer from Juggerbot 3D, a manufacturer of large-format extrusion printers housed at the Youngstown Business Incubator. This machine, the Tradesman Series F3-32, was the first of its kind ever sold. The fused filament fabrication (FFF) 3D printer is distinctive for several reasons. The build size measures 3 by 3 by 2 feet, putting this machine in the medium to large range of extrusion printers. Dual nozzles also enable deposition of two materials independently. But an arguably more important feature is not visible to the casual observer: Where most FFF-style printers apply thermoplastics, the Juggerbot platform can support both thermoplastics and thermosets, even in the same build.

“We mold both,” Emery explains, so having the capacity to print with both types of polymers was important. While the materials can be applied individually, Iten has found opportunities to combine them in overmolding-style applications, like jaws with rubber-like grips and one-off race car parts that require both rigid and flexible areas. The thermoset extrusion capability is somewhat unusual in 3D printing but has proven to be a good fit for the product development and prototyping work Iten commonly performs.

Early Use Cases for 3D Printing at Iten

The Juggerbot machine was still fairly new to the company when I visited in June, but Iten Industries already had some success cases to show, both from this machine and a personal 3D printer owned by Devin Curtis, quality engineer and the company’s primary employee now focused on additive manufacturing.

Many 3D printing applications so far have been prototypes, like a clip for a bulletproof vest that was too difficult for users to open in the original, assembled configuration. Iterating the design through 3D printing allowed Iten to create an easier-to-open version that could be molded in just one piece, ultimately simplifying its tooling and production.

These vacuum attachments were 3D printed before the tool was made to ensure the design would be functional and moldable. Problems identified early on saved hundreds of thousands of dollars in tooling.

3D printed prototypes are also now used to troubleshoot potential injection molding pitfalls before Iten builds the tool. These vacuum attachments (above) were 3D printed in order to check for features that could not be molded as well as validate the fit and performance of the design. Iten was able to save more than $200,000 in tooling costs by catching problems before moving to production with injection molding. 3D printing may add some extra steps to the workflow, but customers benefit from the cost savings and can feel more confident about moving into production with Iten once the design is finalized.

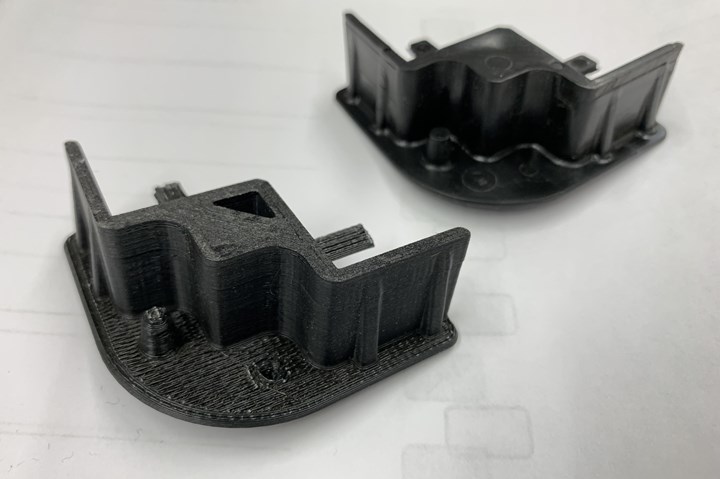

After winning the work to pultrude the straight pieces of a frame assembly, Iten asked, “What else can we make?” The question led the company to develop a more easily moldable corner piece that uses less material (see the 3D printed prototype in the foreground and molded counterpart behind).

The corner pieces shown above are another such example. Iten had already been contracted to pultrude the tubes for a frame assembly, but saw an opportunity to help with the corners as well. Curtis used his personal 3D printer to create a design with less overhang than the original. The change allows for these corners to be injection molded with a less complex tool than was originally considered, which saved cost for the customer and won the work for Iten. The company now produces the full frame assembly — a direct example of the “what else” principle in action, enabled by 3D printing.

While prototyping has always been part of Iten’s work, these cases are of a slightly different flavor than it has previously tackled. The company is now able and willing to do prototypes for complex parts that might not have been practical to prototype in the past.

“We do this work to win the mold.”

“In a lot of cases, those customers wouldn’t have come to us previously,” Emery says. “We do this work to win the mold.” Iten is now serving new injection molding customers with this prototyping capacity, but also expects to enter new industries where 3D printing can be applied for production. An early test for an aerospace company did not win Iten the contract, but allowed the company to learn more about how to serve this space and opportunities it might be able to pursue in the future. Owned products are another potential business opportunity; the company is currently exploring several niche markets where it could sell its own custom 3D printed items directly to buyers.

Devin Curtis and Mike Lilja, toolroom manager, describe the capabilities of Iten’s first Juggerbot 3D printer, which extrudes both thermoplastics and thermosets. Its next 3D printer from the builder will also support the use of pellets, allowing Iten to create prototypes and short run production parts in the same materials it molds today.

Getting to 3D printed end-use part production is part of the plan for the start of Iten’s next hundred years. By the end of 2021, a second Juggerbot machine will join the Imagineering Center. This model will be bigger than the first, and it will utilize a different material format: pellets. Like the existing system it will be able to extrude both thermoplastics and thermosets; however, now Iten will be able to print using the exact same materials it can today injection mold. The material promise opens greater opportunities for initial production runs with the 3D printer, as well as bridge production capability and even 3D printed production straight from prototyping.

Related Content

Aircraft Ducts 3D Printed in Composite Instead of Metal: The Cool Parts Show #68

Eaton’s new reinforced PEKK, tailored to aircraft applications, provides a cheaper and faster way to make ducts compared to formed aluminum.

Read MoreNext-Gen Horse Trailers to Be Built With Robotic 3D Printing

Double D Trailers is currently developing a prototype horse trailer that will be made with large-format additive manufacturing. The technology brings potential benefits for labor, weight and design features to this subset of recreational vehicles.

Read More3D Printing Brings Sustainability, Accessibility to Glass Manufacturing

Australian startup Maple Glass Printing has developed a process for extruding glass into artwork, lab implements and architectural elements. Along the way, the company has also found more efficient ways of recycling this material.

Read More“Mantis” AM System for Spacecraft Uses Induction for Deposition

The metal 3D printing system melts wire without lasers. 30-foot-diameter parts are built on a rotary-feed system that eliminates the need for a large machine frame or gantry.

Read MoreRead Next

The Technology House Steps into 3D Printing for Production

The Technology House was founded on stereolithography for prototyping, but each step forward has been a move toward production. The company is now 3D printing end-use parts, enabled by Carbon’s SpeedCell line and durable materials.

Read More3D Printed Tooling Supports Prototype Foam Seating

Automotive manufacturers and other OEMs require mold tooling to build foam components like seat cushions. 3D printed tools could be a faster, more affordable way to prototype and produce these parts.

Read MorePolymer AM Cuts Costs of Small-Batch Replacement Components

Producing replacement parts through polymer AM has cut Mosca’s lead times and component costs to small fractions of their original size, even when producing small batches of parts.

Read More

.jpg;width=70;height=70;mode=crop)