DMG MORI Powder Bed Machine Sees North American Release

DMG MORI's Lasertec 30 SLM uses a modular powder bed to enable fast material changes between or even during the build.

Share

Read Next

DMG MORI’s first purely additive machine, the Lasertec 30 SLM, recently debuted at the company’s 2018 Innovation Days in Chicago. The selective laser melting (SLM) machine is the first product to come out of the company’s acquisition of German additive manufacturing (AM) company Realizer, and it provides a flexible, economical approach to manufacturing large numbers of parts, including those incorporating multiple materials.

The machine’s principal feature is its detachable powder module, which enables the easy changing of materials without the need for lengthy cleaning. The module reduces the material change-over time to less than two hours, and powders can be swapped both during and between builds, enabling the production of parts with multiple materials. Taking advantage of this quick-change module, the machine can use an array of materials that includes aluminum, titanium, tool steel, cobalt-chrome and Inconel.

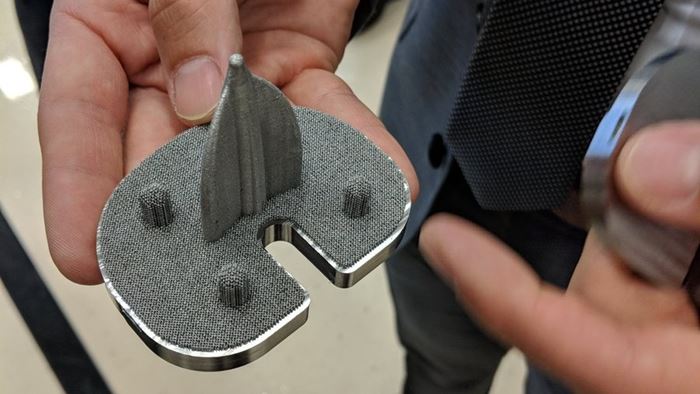

According to the company, even with the release of its first stand-alone powder-bed machine, DMG MORI views additive manufacturing as a complement to traditional production methods. AM processes can supplement and improve upon traditional machining operations, and to demonstrate this the company showed parts produced with a combination of machining and additive manufacturing at its Innovation Days event. One example was a tibial plateau replacement, the knee prosthesis pictured above. The device consists of a machined base plate with 3D-printed features. Machining the base enables faster production and provides a smooth surface where the replacement meets the joint, while the additive process provides light, sturdy lattice structures that encourage bone-tissue in growth more readily than a solid machined piece can.

To accomplish a hybrid workflow, machined workpieces can be loaded into a carrier plate with precision-fit pockets machined into it, which is then loaded into the printer. Object locations are defined through the Celos SLM software. To support 3D printing, workpieces must be machined from a material that is the same or compatible with the metal powder in the printer, as the laser-melting process will damage a workpiece if its melting point is lower than that of the powder. Further, it must have a planar starting surface on which to build.

The company sees its SLM machine as an important addition to its additive offerings, which includes the Lasertec 3D hybrid five-axis machine center. “Both manufacturing technologies complement each other ideally in our product range,” says Patrick Diederich of the companies Advanced Technologies division. While the former can 3D print large numbers of small parts using different materials, the latter can produce and finish larger parts in a single setup. Both are intended to provide production-level additive technology that traditional machine shops can integrate into their offerings.

Related Content

-

3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.

-

Flexible Bellows Made Through Metal 3D Printing: The Cool Parts Show #64

Can laser powder bed fusion create metal parts with controlled flexibility? We explore an example in this episode of The Cool Parts Show.