Can 3D Printed Metal Hold a Vacuum…for Quantum Physics Research?

A feasibility study shows that laser sintered AlSi10Mg can build an ultrahigh vacuum chamber capable of holding a cloud of rubidium atoms. The promise? Lighter, more portable designs to bring research out of the lab.

“Forget everything you know about designing these systems,” says Laurence Coles, computational research engineer at Added Scientific in the UK. Or at least, that’s what he’d like to say to anyone engaged in designing or using vacuum chambers for quantum physics research. These chambers have conventionally been manufactured from stainless steel and designed to integrate with standard off-the-shelf components. The problem? While effective, these chambers are also heavy and tied into to various instruments. This isn’t an issue, Coles says, when they are lab-bound. But the most interesting quantum research is perhaps still yet to come, waiting for the day these vacuum chambers are more easily portable.

That day could be soon. The results of a feasibility study undertaken by Added Scientific in conjunction with the University of Nottingham and the University of Sussex indicate that metal 3D printing is not only a valid manufacturing method for these ultrahigh vacuums (UHVs), but one that offers significant potential benefits for the future of quantum research and applications.

A Chamber for Cold Atom Clouds

The critical component produced during this study is a magneto optical trap, a ultrahigh vacuum (UHV) chamber that is used to hold atoms for quantum research. This type of chamber uses laser cooling and a magnetic field in a strong vacuum (at pressures in the 10-10 millibar range) to contain a cloud of atoms (in this case, rubidium atoms), held at temperatures just barely above absolute zero. When the magnetic field is lifted, the behavior of these cold atoms can be used to study aspects of the environment in which the chamber is placed.

“We can utilize the behavior and the expansion of this cloud of atoms to...more accurately understand a whole range of things.”

“This could be the acceleration of the chamber, the rotation of the chamber, the electrical or magnetic field disturbances around the chamber,” Coles says. “We can utilize the behavior and the expansion of this cloud of atoms to look at gravitational fields or quantum positioning. We can use these quantum devices to more accurately understand a whole range of things.”

Quantum positioning systems could one day replace satellite-based GPS, for instance. But for many of these advances to happen, quantum research has to come out of lab environments — and therefore UHV chambers must become more portable. Long term that will mean smaller, lighter chambers, potentially manufactured additively.

But the magneto optical trap produced by Added Scientific for this study is no smaller than a typical trap, Coles says, and it was designed to integrate with the off-the-shelf hardware already used for these systems. The challenges it was created to meet instead relate to process and material, which together produced weight savings and other benefits in the final chamber.

3D Printing an Ultrahigh Vacuum Chamber

The first hurdle to be overcome was a fundamental one: Would it be possible to 3D print a chamber that could hold an ultrahigh vacuum? Several years ago Added Scientific asked this question at a vacuum expo, and heard “no” from manufacturers and experts who were concerned about the material density and potential porosity introduced in the metal 3D printing process. But going into this project, the quality of the 3D printed material was no longer a concern.

“The challenge is not the achievable density anymore, but what happens to the material when you subject it to vacuum.”

“We were probably capable of doing this quite a few years ago, but advances in processing parameters have increased the achievable densities in the metals with the laser powder bed fusion technique,” Coles says. “The challenge is not the achievable density anymore, but what happens to the material when you subject it to vacuum.”

Virtually any material will outgas under the ultrahigh vacuum environment inside a magneto optical trap chamber. The task, therefore, is not necessarily to avoid outgassing, but to manage it and to select materials that will not contaminate the atom cloud as a result. Stainless steel is commonly used in part because the outgassing behavior is very well understood. This material is also hard enough to enable knife-edge seals at the flanges for attaching other components.

The magneto optical trap made by Added Scientific, however, was 3D printed not from stainless steel, but from AlSi10Mg. Conventional machined aluminum is considered too soft to be used for these high-vacuum applications, but the company posited that a carefully 3D printed and heat treated aluminum alloy might be suitable.

“It’s all well and good putting a piece of the material in the vacuum chamber, but what we needed to do was determine whether or not that same material and the process associated with that material could contain and hold vacuum itself,” Coles says.

Putting AlSi10Mg to the Test

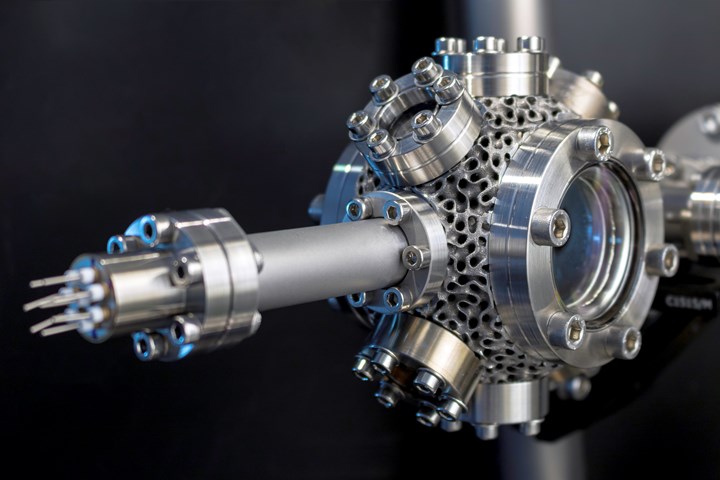

The magneto optical trap made for this study was designed with a combination of SolidWorks and Added Scientific’s proprietary lattice generation software, used to create the matrix-based gyroid lattice on the exterior of the chamber. It was then 3D printed on a Renishaw AM250 powder bed fusion system. After an initial heat treat to relieve residual stresses and homogenize the grain structure, Added Scientific put the chamber through a separate aging process. This second step increased the material’s strength and made it possible to use knife-edge sealing to attach standard vacuum components. After some additional postprocessing, off-the-shelf vacuum components were mounted to the chamber and the entire assembly was “baked out” to clean out contaminants.

The final vacuum chamber with standard components installed. The 3D printed aluminum alloy proved hard enough to enable the knife-edge seals on the flanges, and resisted outgassing under vacuum.

Although conventionally manufactured UHV components have a polished internal surface finish, Added Scientific opted to forgo this step to see if the rough as-printed surface would cause greater outgassing. Tests indicated that a protective oxide layer formed on the aluminum alloy’s surface, which served to suppress outgassing under high vacuum. The final assembly achieved a pressure of less than 10-10 millibar, well within the range needed to retain rubidium atoms. The chamber even held a vacuum without external power or active pumping for 48 hours, hinting at future possibilities for bringing this technology out of the lab.

Added Scientific showed that a 3D printed chamber made from aluminum alloy could therefore be used for cold atom cloud quantum research. But this experiment imparted benefits beyond simple functionality. The prototype magneto optical trap weighs just 245 g, or 70% less than a commercially available stainless steel equivalent. The weight savings comes from the lighter aluminum alloy as well as the mass removed through the gyroid lattice. That lattice also provided an added benefit: Its added surface area enables better heat dissipation.

A closer look at the gyroid lattice on the exterior of the vacuum chamber. Added Scientific also developed the cylindrical insert visible in the lower left corner, which features internal water channels for even more heat dissipation.

Into the Quantum Age

The study confirmed that a 3D printed AlSi10Mg chamber is feasible, but this is only a preliminary step. Future tests will look at reducing not only the chamber’s weight but its size, as a smaller chamber will have less surface area and be more efficient, therefore requiring less power to run.

The addition of the exterior gyroid lattice, as well as a magnetic coil forming insert with built-in water channels, helped to dissipate heat from the chamber, an effect that could be magnified even further in future designs. Coles also sees opportunities to make use of AM’s other benefits such as assembly consolidation (for instance printing connections to avoid the limitations of off-the-shelf components) and easier design iteration to make better UHV chambers for quantum research.

“...we could be moving out of the digital age and into the quantum age.”

“Before you could only make things that you could machine, that you could weld together, that you could produce traditionally,” he says. “What I drive for is to go back to the quantum physicists, the people who use these ultrahigh vacuum systems and say ‘What are you developing? What do you need from it? What features would you like that you can’t have with current systems?’ With this cold atom quantum research, we could be moving out of the digital age and into the quantum age.”

New Opportunities for Quantum Physics: The Cool Parts Show S2E5

We take a closer look at this ultrahigh vacuum chamber and discuss how and why it was made in this episode of The Cool Parts Show, a video series from Additive Manufacturing Media. WATCH

Related Content

With Electrochemical Additive Manufacturing (ECAM), Cooling Technology Is Advancing by Degrees

San Diego-based Fabric8Labs is applying electroplating chemistries and DLP-style machines to 3D print cold plates for the semiconductor industry in pure copper. These complex geometries combined with the rise of liquid cooling systems promise significant improvements for thermal management.

Read More3D Printed Cutting Tool for Large Transmission Part: The Cool Parts Show Bonus

A boring tool that was once 30 kg challenged the performance of the machining center using it. The replacement tool is 11.5 kg, and more efficient as well, thanks to generative design.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreBeehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

Read MoreRead Next

How Exascale Computing Will Enable Born-Qualified AM Parts

ExaAM, a high-fidelity simulation tool, promises to reduce trial-and-error in additive manufacturing and help create metal 3D-printed parts that are qualified from the beginning.

Read MoreHow Machine Learning Is Moving AM Beyond Trial and Error

A Colorado alliance has found the link between AM and AI. Using machine learning to map the formula for successful metal 3D printing, researchers aim to know the right parameters for any new part with few or no test builds.

Read MoreNew Opportunities for Quantum Physics: The Cool Parts Show #11

What does 3D printing have to do with quantum physics? We'll look at how the technology is enabling quantum physics research in this episode of The Cool Parts Show.

Read More

.jpg;width=70;height=70;mode=crop)