The use or adoption of AM tends to play out differently for startups and established manufacturing businesses.

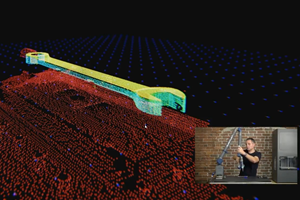

For startups, 3D printing offers a means of achieving speed, flexibility and cost savings over traditional manufacturing methods. AM may make it possible for individuals and businesses to become the manufacturers of their own products, when production would be cost prohibitive otherwise. 3D printing allows these businesses to avoid the startup costs of mold tooling; to launch a product even while still tweaking its design; and to manufacture goods on demand, with no need to meet a minimum order requirement.

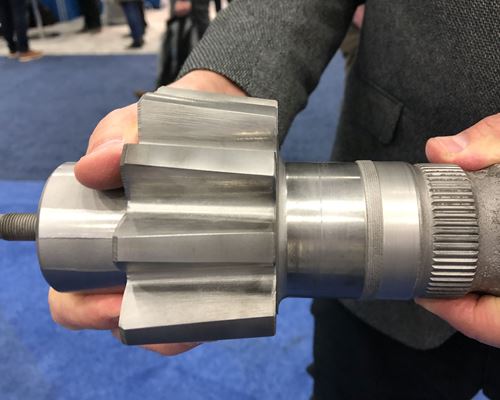

Established businesses stand to achieve many of these same benefits, but may have incumbent processes, equipment and suppliers that make adoption slower and more difficult. In large companies, adoption tends to begin with prototyping and then tooling such as jigs and fixtures before AM is integrated as a production method. Spare parts are a strong use case for 3D printing, as are new products.

Both scenarios demand strong support from leadership and “AM advocates” with the power and vision to see adoption through.

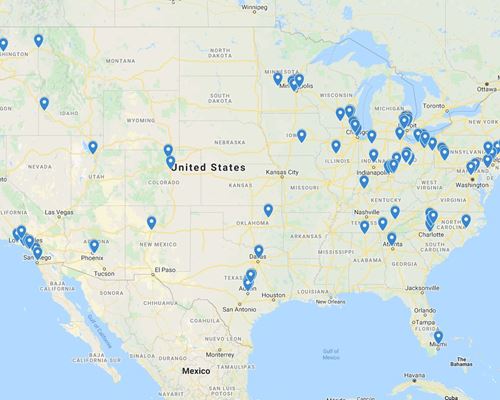

Some businesses may find that it doesn’t make sense to own the 3D printing capacity outright, but to instead contract the work to an external supplier temporarily or indefinitely. New types of manufacturing companies set up to serve external clients are now allowing some creators, makers and inventors to launch and sell products without owning most or any of the production capacity themselves.