Building an Additive Manufacturing Business for Production

What does it look like to build a business based on AM production from the ground up? An Ohio medical device contractor is finding out.

Additive manufacturing (AM) is often described as a process that builds parts "from scratch," meaning that the end product doesn't emerge from a solid piece of existing material, but instead is created layer by layer, from the bottom up. Building parts this way removes many of the constraints imposed by traditional machining. However, it also comes with its own set of unique challenges.

Additive manufacturing company Tangible Solutions is in the midst of working through those challenges. Located near Dayton, Ohio, the company is a contract manufacturer with a focus on the medical device industry. But unlike other, established contractors who have added AM to existing machining capacity, Tangible is working from the ground up to build a business designed solely for AM production. In a sense, Tangible is developing a manufacturing business and a production process from scratch.

Getting to the point of production has not been easy. In just under four years, Tangible Solutions has moved from a home garage to rented office space, back to a garage, and finally to its production facility, a 25,000-square-foot space in Fairborn, Ohio, a Dayton suburb. When I visited, the company was still working on process development and procuring the necessary ISO, ASTM and FDA credentials for medical device manufacturing, with customers preparing to move into AM production. The journey is still in progress, but offers valuable lessons already.

Defining the Business

"At our core, we are an additive manufacturing company," says Adam Clark, Tangible Solutions CEO. "Manufacturing" here is the key word. Tangible's focus is on AM part production, and as a result it is not engaged in equipment sales or other services offered by more broadly focused service bureaus. "We will help our customers modify their product design to work for AM, but our goal is to make the parts," says Clark.

In its beginnings, Tangible did offer prototyping, modeling and general 3D-printing services. Then a customer asked if the company could 3D print short runs of a sensor used on power lines. The sensor (typically injection molded) featured Bluetooth capability and a number of embedded electronics, which were constantly changing. By printing these sensors in batches of 200 to 300 as they were needed, Tangible saved the customer the cost of inventory and the $35,000 investment in a mold each time the design changed.

“At our core, we are an additive manufacturing company.” —Adam Clark, CEO, Tangible Solutions

This job proved to be the turning point for Tangible Solutions, when the team decided that the company’s future was in additive manufacturing for part production. And rather than trying to be a jack-of-all-trades, it chose to focus on the manufacture of one specific type of product: medical devices, initially starting with spine implants. Mid-market companies in this space (the customers Tangible now serves) tend to be open to education about AM, more flexible and capable of working on the type of aggressive timelines the company hopes to achieve. (Its goal is to stay within 20-day lead times—dramatically faster than the 90-day time frame spine implant manufacturers are accustomed to.)

After zeroing in on orthopedic implants, starting with those for the spine, the company reached out to medical device companies, doctors and other healthcare professionals to build its business. Following this vision meant that Tangible had to “fire” some of its customers whose needs didn't match what the company wanted to provide. It also meant avoiding prototyping work, as well as saying "no" to odd jobs just to keep machines running.

"That made me very nervous, going from a large pipeline of work down to just a narrow stream," says Clark. "But found that once we narrowed our focus, we were able to grow it back quickly with the types of customers we wanted." Now, the focus is on just a handful of customers who share Tangible’s same commitment to additive manufacturing of medical devices.

The Best Vendor, the Best Customer

In tandem with its laser focus on medical, Tangible Solutions is also working to establish a “culture of production” both within the organization and externally. Taking on new business is as much about culture fit as it is about Tangible’s ability to meet customers’ needs. “We will commit to you if you commit to us,” Clark says of the company’s approach. The ideal customer is one who will work with them as a partner, not just as a client.

To tease out whether a potential customer fits the bill, there’s an initial “interrogation” process, Clark explains, in which Tangible seeks to gage how familiar the prospect is with AM and the seriousness of the opportunity before the conversation goes too far.

Tangible’s prototyping policy is another screening step: Potential customers who want a prototype must pay for it. This isn’t about the expense of producing the prototype; instead, it’s a test. A prospect who’s not willing to pay for the work is likely not ready to make the commitments necessary to move into AM production alongside Tangible.

“We rely on our customers to teach us about their market and their business, and we educate them about our technology in return,” Clark says. “It’s a partnership all the way through.”

That knowledge exchange is continuous, even for existing customers. With each new product, there’s a mediating process in which Tangible lays out all the specs for the part and identifies the sticking points. Then, the team goes over these with the customer, asking questions about which features are critical, where tolerances can be relaxed and whether the batch size can be changed.

For example, it might be that a customer orders a batch of 14 implants, but only 13 fit comfortably on the build plate at a time. At that point, Tangible would question whether the company needs the full 14 and explain the added expenses involved in setting up and running the job a second time.

The educational process also extends to suppliers—the outside vendors who provide services such as laser marking, spot passivation and HIPing to Tangible. “Many of them haven’t seen or worked with additive parts before working with us,” Clark says, so Tangible brings the same teaching approach to these business relationships. “We want to be the best customer, and the best vendor,” he says.

Setting Up for Success

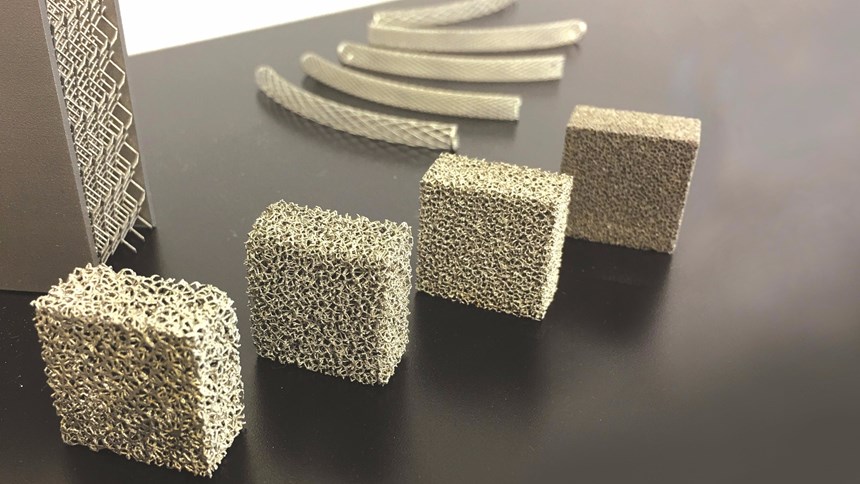

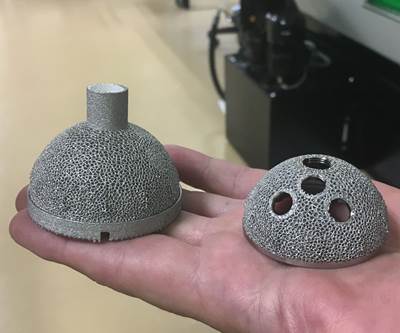

Becoming a standout vendor will take intimate understanding of the systems and variables at work, and Tangible is working to build a body of knowledge that will make this possible. Currently, Tangible Solutions owns six Concept Laser additive manufacturing systems housed in the metal AM portion of its facility, made up of five Mlabs and one M2 cusing machine (four polymer 3D printers used for prototyping medical devices, models and instrumentation are located in an adjacent area). The metals area also includes a Mitsubishi MV2400-S wire EDM and two dedicated Hurco VM10U HSi machining centers.

Because it is time-consuming and costly to safely change over from one metal to another, the use of the equipment is dictated by material. The smaller Mlab machines build in reactive titanium, and one of the machining centers (which is equipped with glass linear scales) is designated for machining these parts. The second machining center is open for other materials used in the M2. The primary use of both machining centers is tapping holes, as tapped holes are a common feature that AM is not well-equipped to handle. For deburring, there are also two separate blast cabinets to accommodate different materials.

In this case, success isn’t necessarily about making lots of parts; rather it’s about minimizing risks and keeping the process under control.

Regarding the additive machines, the use of so many Mlab machines might seem odd to some. Their size and the very name of the machines suggest use in a research laboratory setting, not a production environment. However, Tangible is discovering that these smaller machines are actually ideal for production of medical implants.

With metal powder-bed AM, “You’re essentially buying the powder first,” says Chris Collins, chief operating officer. A smaller machine means less powder is needed to fill the bed. The Mlabs also have a smaller beam diameter, which makes them more precise, and the smaller batch sizes mean that if something interrupts the process—say, the facility loses power—the loss will be smaller, Collins explains. In this case, success isn’t necessarily about making lots of parts; rather it’s about minimizing risks and keeping the process under control.

When I visited, Tangible was in the process of procuring ISO 9001 and ISO 13845 certification and registering with the FDA as a Class III medical device manufacturer. Doing this is not as straightforward as it sounds. Unlike machining or molding, the variables that must be controlled for AM production are not well established, and they are also far from obvious. Tangible is therefore thinking through all of the potential failure modes in a process that relies on AM and figuring out how to address them.

During my visit, Tangible was in the process of running sample parts which it then tests in-house or sends out for spectrometer scanning and chemical testing to build its own internal data about the range of variation in its process. Information on the expected outputs from metal additive manufacturing exists, Collins says, but as a production company Tangible needs to know what, specifically, it is delivering with the materials, equipment and processes it has in place. One way the company is building its own proprietary knowledge is by producing sample parts and testing them to measure the variation not just from machine to machine, but also for different positions of the build plate within the same machine.

But as critical as it is to ensure repeatability across the additive systems, Collins says the build itself is only 60 percent of the entire additive manufacturing process. Other critical aspects include:

- Materials. Tangible considers itself a beta house for AM production only, not for proving out materials or new equipment. Its focus is on finding the most affordable sources for its validated materials; keeping them inert before, during and after production; and figuring out how many times material can be reused.

- Supports. “We don’t design parts. We design supports,” Clark says. The latter can present a design challenge comparable to the former. Providing enough support to hold the part during the additive build is critical, but it’s also important to avoid overengineering supports and potentially damaging the build plate. Rather than fusing a part solidly to the build plate, Tangible makes an effort to design support structures that keep the part a little above the plate, making part removal easier. In some cases, building supports this way even makes it possible to remove the parts from the build plate by hand.

- Build plates. The support strategy described above has another advantage: The ease of part removal protects the build plate from having excess material removed along with the part. It is important to prevent this because a plate that becomes too thin will not be able to stand up to the distortion caused by the powder-bed process. Ultimately, these plates—vital pieces of tooling—will be tracked and logged in an ERP system just like production parts.

- Postprocessing. Currently, when built parts are completed, they are removed from the machine via a glove box and then an employee wearing personal protective equipment (PPE) washes the parts with liquid, typically deionized water or mineral oil. The parts are then removed from the build plate, either by hand or using the wire EDM. From there they may go into a blast cabinet or travel off-site for processes such as heat treatment or HIPing. Each of these steps introduces variables that need to be standardized and documented.

- Inspection. Tangible is still working through validating the inspection process for medical devices. Methods currently being explored include the use of hand gages and a 3D scanner in-house, and outsourced methods such as CT and radiographic scanning; but ultimately, the inspection choice will depend on customer needs, wants and budget. By proving out the consistency of the AM process, Tangible is accruing data that will keep inspection from being a burden. “By building that case, we are allowing ourselves the freedom to not inspect every single part,” says Collins.

Beyond the technology, there’s also a human element to be addressed.

“A bottleneck for our industry right now is workers,” Clark says. That’s one reason Tangible has made a significant effort to partner with local community colleges such as Cincinnati State and Sinclair Community College. It’s also looking at local high schools as a potential source of employees. One of its most recently hired employees is an 18-year-old graduate who earned experience with machining, EDM and other conventional technologies while in high school.

Even so, “We’re running on a skeleton crew right now,” says Collins. The company has 11 employees currently, but hopes to grow that number to 20 or 25 by the end of 2017. Maintaining and increasing the workforce will be an ongoing challenge, he says.

Next Steps

There’s plenty of room to grow in the Fairborn facility, but what that growth looks like in the immediate future is not yet obvious. “The bottleneck could be machining, so maybe we’ll need another CNC next,” says Collins. “Or maybe it’ll be adding another plastics printer.”

The ultimate plan is to “duplicate and segregate,” Clark says. After solidifying its medical business, the plan is to take the lessons learned and use them to establish Tangible Solutions Aerospace. The aerospace industry is ready for additive manufacturing, Clark says, but not yet for contract additive manufacturers. When it is, Tangible hopes to help fill that void.

Related Content

Zeda AM Production Plant in Ohio Now Open — Thoughts on the New Facility

73,000-square-foot metal powder bed fusion plant includes extensive machining capability plus separate operational models for serving medical versus other businesses.

Read MoreNew Zeda Additive Manufacturing Factory in Ohio Will Serve Medical, Military and Aerospace Production

Site providing laser powder bed fusion as well as machining and other postprocessing will open in late 2023, and will employ over 100. Chief technology officer Greg Morris sees economic and personnel advantages of serving different markets from a single AM facility.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Video: Smith & Nephew on 3D Printing Patient-Specific Surgical Instruments

Using MRI and additive manufacturing to produce a cutting block customized to the patient aids the precision of the surgery.

Read MoreEnd-to-End Additive Manufacturing at Slice Mfg. Studios

The Akron-based company aims to control and perfect the additive manufacturing of medical devices, from raw material all the way through shipping.

Read MoreWhen Additive Manufacturing Becomes Business As Usual

Medical implant manufacturer Tangible Solutions has had its share of growing pains to arrive at full-scale production via AM. But now, the company’s challenges are those that any contract manufacturer might recognize.

Read More

.jpg;width=70;height=70;mode=crop)