We at Additive Manufacturing Media have cited materials as a key component and challenge to the adoption of additive manufacturing (AM) in the past. We’ve given attention to alloys that are finding their footing in metal 3D printing, and to polymers carefully formulated for specific applications. But do successes like these tell the whole story of materials for 3D printing? Does the challenge of materials in AM boil down to a need for variety of new and different 3D printing material options?

Matt Torosian would say no; there is more to consider. “Not everything is about breakthrough properties,” he says. “Matching properties of existing materials is also important. 3D printing materials need to be consistent, reliable and certifiable.” The real hurdle to overcome with 3D printing materials, it turns out, might be confidence.

Torosian is director of product management for Jabil. Sometimes referred to as “the biggest company you’ve never heard of,” Jabil has more than 200,000 employees spread across 100 facilities in 26 countries. As one of the largest contract manufacturers in the world as well as a supply chain, product management and design company, Jabil has global capacity for CNC machining, injection molding, assembly and numerous other manufacturing operations—now including additive manufacturing.

Indeed, in additive manufacturing, Jabil is quickly becoming a force to be reckoned with — as a massive 3D printing user, manufacturer of 3D printer parts, and, most recently, the power behind a brand new Materials Innovation Center in Chaska, Minnesota.

When I visited this facility in late April with Editor-in-Chief Peter Zelinski, we were the first members of the press to set foot in the building — all the more notable considering that the Materials Innovation Center was originally conceived as a completely clandestine laboratory. But generating press attention wasn’t the key reason the Center opened its doors; instead, the impetus came from customers using its services. In order for those 3D printing users to have confidence in the materials developed here, they needed to be allowed inside and made active collaborators in the process.

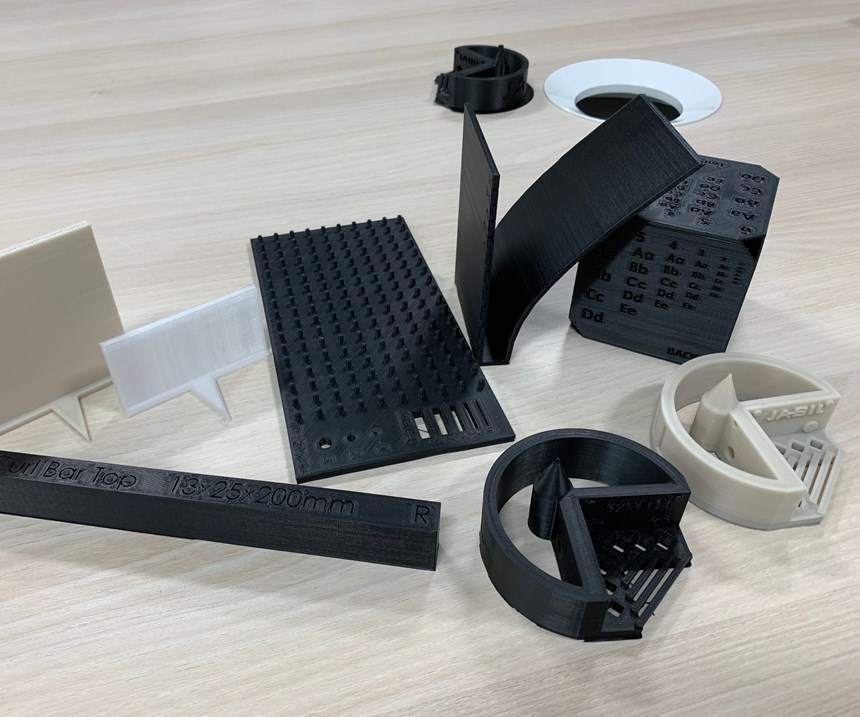

The Materials Innovation Center is an end-to-end facility for developing, testing and manufacturing polymer powders and filaments for 3D printing. In a nutshell, its goal is to be able to take application requirements — from Jabil or external customers — and convert them into materials that can be printed.

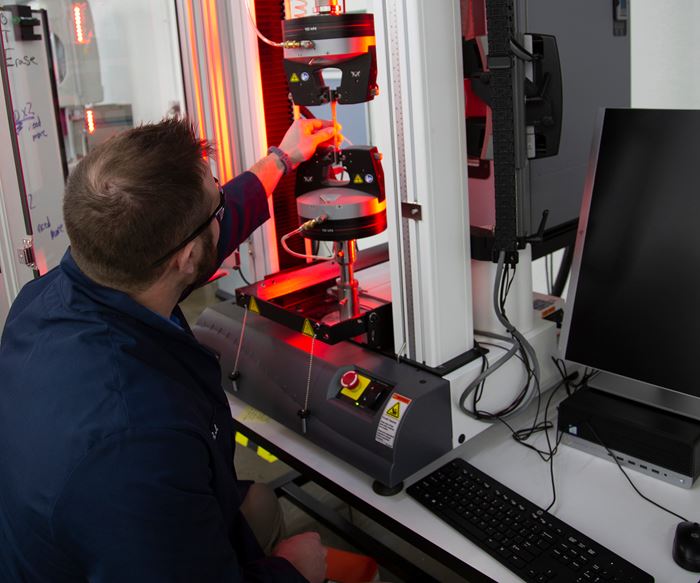

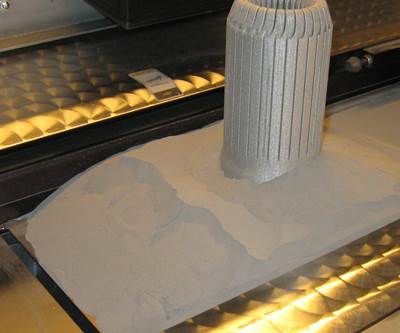

The 46,000-square-foot space is set up for research and development through the pilot launch of a material, Torosian says. The main space that is available for visitors to see is a lab filled with mechanical testing machines and chemical analysis equipment used in characterizing existing or newly developed polymers. Beyond this lab, the facility is also equipped with chemical reactors for polymer compounding; extrusion, precipitation and grinding for material production; and 3D printers from various builders for process development.

Identifying and Filling Materials Needs

Jabil established this center having identified a need for AM materials, and with some idea of the material properties that were lacking in current polymer options. However, the center is not operating in a vacuum, but pursuing customer-requested materials alongside Jabil’s own. At the time of our visit, Jabil had more than 40 projects in the works, at least eight of which were direct customer material requests.

Many of these development projects are “fitting into some of the buckets that we already thought were there,” Torosian says. For filaments, those buckets include higher impact strength and autoclavability. For polymer powders, the focus tends toward variations in flexibility or rigidity, as well as electro-static dissipative (ESD) properties.

Creating new materials is only one objective; establishing confidence in existing materials for new applications is just as useful and valid.

By developing materials with these properties, Jabil is helping to fill known gaps in AM materials. However, the company also finds opportunities to kill a few birds with the same stone where it can. Having access to a range of customers and application requirements at once allows the company to find overlap, where the same material might work for multiple applications. Creating new materials is only one way Jabil serves AM users; establishing confidence in existing materials for new applications is just as useful and valid.

“Where we don’t match, we’ll develop. Where we do, we’ll plug in,” Torosian says.

But creating or translating material formulation is only part of the overall strategy, which Jabil calls its “Materials, Process, Machine” approach. Materials in development are printed using fused filament fabrication (FFF), selective laser sintering (SLS) or high-speed sintering (HSS) printers available on-site, not only to generate samples for testing, but to help build print profiles. The goal is to push out materials that work reliably with known parameters on specified machines. Once a filament or powder meets this objective, the Chaska facility will have served its purpose and full-scale production can pass to a compounding partner.

Distributed Additive Manufacturing for Production

But why would Jabil, an AM user rather than materials supplier, establish such a facility? Why create the materials itself?

Again, it comes back to confidence. Jabil anticipates a future in which it will routinely use 3D printing as a high-volume production solution, with facilities distributed around the globe; to get there will require reliable sources of dependable, predictable materials. Today, materials sources serving additive manufacturing tend to be capacity-constrained relative to the potential demand of a producer like Jabil, or tend to be single-source providers of materials that are proprietary. Neither scenario offers sufficient safeguard against production interruptions. Therefore, Jabil is not simply or even primarily out to create materials, but instead to ensure that there will be adequate quantities available. “We want to be the reliable supply chain solution,” Torosian says.

But it’s one thing to develop the material and work out the process with printers available in Chaska; it’s another to keep printing reliable parts from various lots of the material, in different machines, and in various geographical locations. A company like Jabil — with 3D printing capacity on three continents — is set up to do the legwork required.

“We want the confidence to produce anywhere.”

If the company is successful at developing proven, dependable materials to be manufactured in production quantities, the payoff could be significant. Rather than manufacturing entire production runs of specific parts in designated facilities, Jabil continues to build out its distributed manufacturing strategy — making production parts near where they will be used, even if that means dividing the volume across facilities, countries or continents. Material success will therefore be the enabler to an entirely different form of production.

“We want the confidence to produce anywhere,” Torosian says.

More on Additive Manufacturing for Production at Jabil

What does Jabil plan to do with these materials? What kinds of production AM will take place? And where is all this headed? Find more of our reporting at gbm.media/jabil.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read MorePossibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreUnderstanding PEKK and PEEK for 3D Printing: The Cool Parts Show Bonus

Both materials offer properties desirable for medical implants, among other applications. In this bonus episode, hear more from Oxford Performance Materials and Curiteva about how these companies are applying PEKK and PEEK, respectively.

Read MoreRead Next

AM at Jabil: From 3D Printing Materials to Distributed Manufacturing

One of the largest manufacturers in the world has made a significant investment in 3D printing — both as a user and an advancer of this technology. Our original reporting dives into the what and why of additive manufacturing at Jabil.

Read MoreJabil Emerges as a Powerhouse in Additive Manufacturing

Jabil, an international force in manufacturing, software and services, has launched a global network of additive manufacturing services.

Read MoreMaterials Are the Most Important Component in AM

You will see a lot of additive machines at IMTS. Success with those machines is determined by an underappreciated ingredient. Read our collection of recently published articles focused on materials.

Read More

.jpg;width=70;height=70;mode=crop)