AM Helping AM: 3D Printed Build Plate Detects Build Failures

Ultrasonic additive manufacturing produces a build plate with embedded sensing, allowing for real-time measurement of the condition of the build. If a failure occurs during selective laser melting, this plate will reveal it immediately.

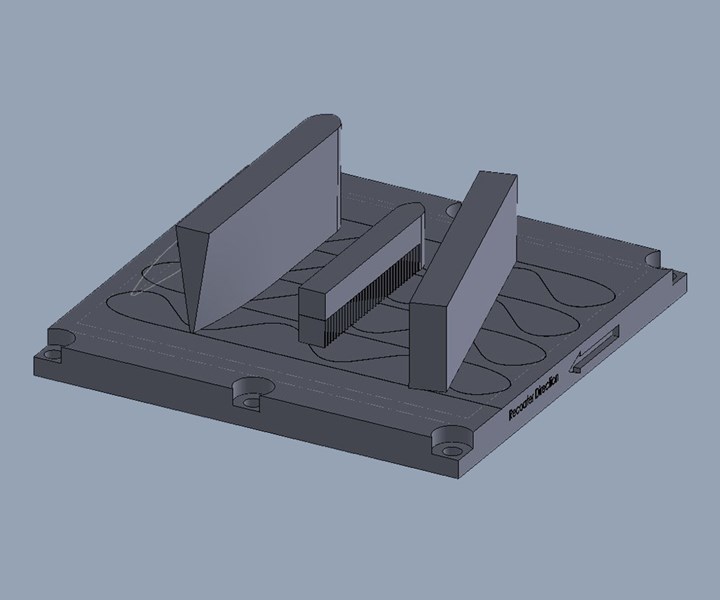

The build plate is a basic component of any selective laser melting build: Metal components are 3D printed directly onto it (and usually must be cut off after the build). This drawing of the smart build plate also shows metal 3D printed forms used to test it. The snaking line seen here indicates the fiber optic cable inside the plate that allows for strain measurement in vector directions. Solid-state AM made it possible to create a solid metal plate with sensing inside, as described in the article below and the video linked at the end.

We’ve seen examples of 3D printing being used to make components of 3D printers. This is a natural way for developers of additive technology to leverage their own platforms. However, Fabrisonic has an example that is different in an important respect: The company uses its additive process to aid an altogether different additive process. The company has applied its ultrasonic additive manufacturing (UAM) technique to create a “smart” build plate able to safeguard the build in powder bed fusion.

The plate detects build failure. Fiber optic sensing contained within the plate allows the user to capture real-time data on stress, temperature and strain as a metal part is printed onto it via selective laser melting (SLM), a powder bed fusion process that uses a laser to melt thin layers of powder to build up the part.

Detecting a build failure does not save the part, but it can save hours upon hours of productive time.

Measuring strain is particularly significant. The plate’s sensing captures strain vectors throughout a grid along the surface of the plate. As long as these vectors are stable or changing gradually, the build is liable to be fine. But a strain vector changing abruptly indicates that something has broken. A build failure has occurred, likely scrapping the part. Detecting the event in this way does not save the part, but it can save hours upon hours of productive time, thanks to the chance to stop the build right when the failure occurs rather than completing the build and discovering the failure only at the end.

Ultrasonic additive manufacturing was necessary to realize the smart plate; SLM, which operates at much higher temperatures to melt the metal, could not have produced it. The ultrasonic AM process, which Fabrisonic pioneered, builds solid metal parts out of thin layers of metal foil by using ultrasound to bond these layers together. The room-temperature process is solid-state; there is no melting. That feature of the process allows for the chance to embed sensors or electronics into solid metal parts by laying them in as the build progresses. The embedded component is unharmed as the rest of the part is built around it, sealing it in.

The kind of monitoring the smart build plate provides aids in assuring the effectiveness of SLM as a production process. This plate therefore represents not just additive helping additive, but one AM process helping another AM process to realize its promise.

The Cool Parts Show devoted an episode to the smart build plate. Watch to learn more about ultrasonic AM and how the plate will get even smarter.

Read Next

Can 3D Printing Make a Better AM Build Plate?: The Cool Parts Show #5

Ultrasonic metal additive manufacturing was used to create a build plate aimed at making powder bed fusion more effective. This episode of The Cool Parts Show looks at a part by AM, for AM.

Read More3D Printer Parts Made with 3D Printed Tooling: ExOne Walks the Walk

Accelerated timelines, fast design changes and low volumes — in many ways, 3D printing is the right market for 3D printing. ExOne’s newest generation of machines includes parts vacuum formed on 3D printed tools developed by Catalysis Additive Tooling.

Read MoreHere Is What a Four-Laser Machine Can Do—and Here Is the Hardware Used to Do It

One laser gets you this far. Two lasers get you this much farther. These productivity comparisons with a four-laser machine also show the cooling geometry that brings four lasers together.

Read More