Cameras, crucial to filmmaking, are geometrically complex by nature and demand user proficiency. Especially when it’s needed for the continuation of one of the most groundbreaking film franchises of all time.

James Cameron, shoots in action, utilizing the camera rig with 3D printed components courtesy of SNL Creative Inc. Photo credit: SNL Creative

“Avatar: The Way of Water” premiered in 2022 after more than a decade hiatus since the original films’ release. The creator, James Cameron, bid his time, waiting for an array of technological advancements vital to delivering the intended vision for the sequel. One such solution was born of additive manufacturing (AM).

Lindsey Zindroski, CEO of creative additive service bureau SNL Creative Inc., was approached by the director of 3D camera technology from Lightstorm Entertainment and 20th Century Studios Inc. back in 2019 for the opportunity of a lifetime. In search of an additive solution, the director required custom, 3D printed camera components for the 3D stereoscopic camera rigs for the filming of “Avatar: The Way of Water.”

The Additive Partnership Is Struck

Stereoscopic rigs serve as compounded devices to mount two cameras into one 3D system for the purpose of capturing and enhancing the illusion of depth as related to image and film. According to Zindroski, Lightstorm Entertainment and 20th Century Studios required custom designed and fabricated parts for these complex camera systems, including the beamsplitter mirror box, camera tracking system enclosures, clamps, and supports for the camera lenses in the final builds.

Zindroski says when combined, these components create the camera housing, serving as the external frame for the lenses, mirrors, cables and electronics residing inside. The beamsplitter mirror box, in particular, is critical as it proves a large portion of the camera enclosure. Zindroski shares that it’s inside this enclosure where the magic really happens and, thus, the internal equipment must be handled equally; properly supported and protected.

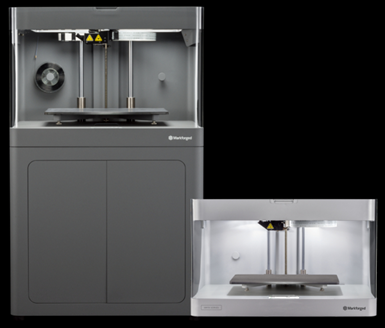

SNL Creative used these fused filament fabrication (FFF) printers from Markforged to produce the smaller camera components with carbon fiber-reinforced nylon. Photo Credit: SNL Creative

Fortunately for the production team, SNL Creative focuses on composite 3D printing of end-use parts for the very purpose of low-volume production and does indeed leverage Markforged printers, among others. According to Zindroski, in total, SNL Creative printed more than 25 separate camera components for the film along with five camera housings.

Robust Requirements: Meet the Machines

In seeking professional expertise to custom print camera parts, Lightstorm Entertainment and 20th Century Studios expressed that the pieces needed to accommodate various requirements per Cameron’s request as follows:

- Serve as a suitable alternative to aluminum fabrication for several live-action camera systems.

- Provide enhanced material strength as well as structural integrity.

- Offer excellent tolerance accuracy (to accommodate other components being added, fit on or bolted to existing structures).

- Be black in color and offer a smooth surface finish (to meet professional standards of on-set equipment).

- Be made from a lightweight material, meeting the 30-lb weight limitation (parts were created with the intention of being used in handheld cameras).

Determined to rise to the challenge and provide camera components meeting these conditions, SNL Creative utilized 3D printing technologies and composite AM materials from providers Stratasys and Markforged.

SNL Creative used printers from Stratasys to produce the larger camera components with the ideal substitute for aluminum material: nylon-carbon fiber polymer. Photo credit: SNL Creative

Size proved the essential factor in determining which machine would be used for the various camera components. For the creation of the larger camera pieces, SNL Creative implemented Stratasys technology, utilizing the Fortus 450mc machine, a printer chosen for its upgraded hardware and extrusion head. Enabling a high-performance, nylon-carbon fiber polymer, the Fortus machinery is equipped to run this ideal alternative to aluminum with respect to strength and product finish.

On the smaller side of the part size spectrum, Markforged machinery was selected to print the smaller camera components. Specifically, the Markforged X7 printer was used, as it reinforces parts with carbon fiber and Kevlar infills for increased strength and durability. Zindroski says additive-based nylon carbon fiber (in addition to replacing heavy weight aluminum) significantly reduces manufacturing costs and lead times.

The Way of Weather (Natural Forces Behind the Scenes)

To satisfy outside requirements (quite literally), SNL Creative was tasked with creating parts with more than just the previously mentioned constraints. Zindroski says much of the film was shot in New Zealand, where the natural amount of humidity proved a large consideration in terms of part durability. With all the moisture laden in the air, the 3D printed parts needed to be built to endure the damp climate. The chosen material (with good reason), nylon carbon fiber, combats the intense moisture in the air as it is a corrosion- and water-resistant material.

The ability to manipulate materials and geometries equips additive to take on outdoor applications, such as filming in natural environments and being adaptable to the surrounding elements. SNL Creative delivered the necessary parts in time for filming, and the camera rigs were used throughout the shoots.

“For time frame reference, we printed the camera parts around 2019 and filming wrapped in 2021. It’s a testament to the durability, robustness and capacity for customized geometries that 3D printing offers,” Zindroski says.

That’s a Wrap

Ultimately, James Cameron, as well as the director of 3D camera technology for “Avatar: The Way of Water,” knew the custom geometry solutions required were only possible through 3D printing.

“Known for custom building his cameras, James Cameron sought additive to assemble the necessary camera components for the filming of “Avatar: The Way of Water,” Zindroski says. The complete customization layer that additive offers not only met but exceeded the directors’ expectations.

Zindroski shares she was in awe of the project, from start to finish, learning from some of the best camera technologists about 4D image capture. Witnessing how the pieces came together on set, in-studio, and the process of problem-solving accompanying it was insightful she says.

“I’m beyond grateful for the experience and I truly don’t think it gets any better than sharing additive manufacturing expertise with James Cameron and his crew,” Zindroski says.

Related Content

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read MoreThis Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

Read MoreActivArmor Casts and Splints Are Shifting to Point-of-Care 3D Printing

ActivArmor offers individualized, 3D printed casts and splints for various diagnoses. The company is in the process of shifting to point-of-care printing and aims to promote positive healing outcomes and improved hygienics with customized support devices.

Read MoreRead Next

Markforged Expands Offerings with Larger 3D Printer

The FX20, Markforged’s largest and fastest 3D printer, is appearing at IMTS for the first time.

Read MoreRekkie AR Ski Goggles Made Possible With 3D Printing: The Cool Parts Show #53

When the electronics enclosure key to these AR goggles proved difficult to mold, 3D printing allowed the inventors to keep the complexity — while also making improvements for assembly and user experience.

Read MoreStratasys Showcases Four Years of New Technology

Stratasys has added several new 3D printing technologies and machines since 2018, many of which are making their IMTS debut.

Read More