ESSENTIAL READING

VIEW ALLFitz Frames Brings Mass Customization to Eyewear with Affordable 3D Printed Glasses Frames

Glasses don’t need to be ill-fitting and frustrating to buy. Fitz Frames offers a different kind of shopping experience (using augmented reality and 3D measurement) to produce custom glasses with 3D printed frames that are affordable, durable, comfortable and stylish.

Read MoreLatest Consumer Goods News And Updates

Italian Furniture Maker Uses WASP Technology to Create 3D Printed Pendant Lamps

The versatility of 3D printed ceramic enabled the designers to shape a weave reminiscent of the beehive concept, enhanced by the light source.

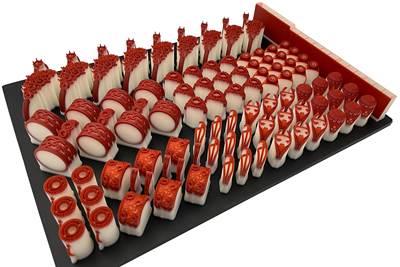

Read More3D Systems Offers MJP 300W Printer, Wax Material for Advanced Jewelry Additive Manufacturing

The combination of the MJP 300W jewelry printer and VisiJet Wax Jewel Ruby enables jewelry designers to more efficiently achieve new designs with greater design freedom and improved surface finish.

Read MoreEOS Launches Digital Foam Architects Network

EOS created the collaborative additive manufacturing alliance to accelerate time-to-market for 3D printed foam applications.

Read MoreChromaMotive D65 Parts Perform Well in Range of Extreme Temperatures

Formnext 2023: The Shore D thermoset polyurethane is well suited for applications that have varying temperature requirements, in a range extreme cold to elevated temperatures from -30 up to 120°C.

Read MoreHP Works With Brooks Running to 3D Print Performance Footwear

HP has collaborated with Brooks Running to create the Brooks Exhilarate-BL which features 3DNA, a 3D-printed midsole technology that delivers a propulsive, bouncy ride.

Read MoreMaterialise’s Translucent Material Expands Eyewear Design Capabilities

The company opens up new design possibilities with the fusion of 3D printing and translucent material.

Read MoreFeatured Posts

Sustainable Furniture Company Model No. Maintains Product Focus with Switch from DIY to Industrial 3D Printers

The startup founded in 2018 has matured in its product offerings as well as its manufacturing equipment, moving from homegrown 3D printers to industrial large-format machines.

Read MoreHow Production Looks Different for 3D Printed Furniture Manufacturer Four Years Later: AM Radio #50

Furniture manufacturer Model No. has shown that there is a demand for customizable, sustainable 3D printed tables, chairs and more since we last covered the company in 2020. But today, production looks different.

Listen3D Printed Ductile Spikes for Better Sound Quality: The Cool Parts Show Bonus

Work on 3D printing flexible metal bellows has led to other applications, including the development of ductile spikes that sit between a speaker and the surface below to help limit vibration and isolate the audio equipment.

WatchFeatured Media

Rekkie AR Ski Goggles Made Possible With 3D Printing: The Cool Parts Show #53

When the electronics enclosure key to these AR goggles proved difficult to mold, 3D printing allowed the inventors to keep the complexity — while also making improvements for assembly and user experience.

WatchNew Electric Dirt Bike Is Designed for Molding, but Produced Through 3D Printing (Includes Video)

Cobra Moto’s new all-electric youth motocross bike could not wait for mold tooling. Parts have been designed so they can be molded eventually, but to get the bike to market, the production method now is additive manufacturing.

Watch3D Printed Putter Tailored to the Golfer: The Cool Parts Show #49

An engineering student in South Africa used metal and polymer 3D printing in tandem to create a putter customized to the individual golfer’s swing.

WatchFAQ: Consumer Goods

Can sporting goods or equipment be 3D printed?

Yes, 3D printing customizable components is particularly useful for sporting goods. For example, Rawlings produced a baseball mitt with 3D printed thumb and pinky inserts. A student in South Africa designed a customizable 3D printed golf putter, featured on this episode of The Cool Parts Show.

The baseball mitt was produced through Carbon’s Digital Light Synthesis with FPU 50, a flexible polyurethane.

The putter was made with 314 stainless steel through laser powder bed fusion on an M290 machine from EOS.

How do the fashion, jewelry and cosmetic industries use 3D printing/additive manufacturing?

Additive manufacturing’s complex design and customization capabilities can be beneficial for the fashion, jewelry and cosmetic industries.

Examples include:

- Hilos’ custom heels and Retraction Footwear’s flip flops that promote circular fashion and sustainable manufacturing

- A collaboration focused on enabling the production of functional stainless steel accessories for the jewelry and fashion markets

- Adjustable “pucks” for L’Oreal that resulted in a 33% cost reduction and 66% time savings

Why is 3D printing/additive manufacturing good for consumer goods?

3D printing offers boundless customization and often requires less lead time than conventional manufacturing methods that would require tooling to be produced.

How does additive manufacturing or 3D printing contribute to a circular or sustainable economy?

One example of this is Retraction Footwear’s approach:

“The company’s 3D printing process applies material only where it is needed, generating far less waste than conventional shoe manufacturing. The flip-flop design features an air cushioning system inside the sole which farther reduces the material used, and each design is right-sized to the customer. The thongs are manufactured with just 12 desktop 3D printers, each optimized to use only 50W of energy, or about as much as it takes to operate a standard light bulb. The product itself is made to order, preventing wasted inventory and providing the consumer with shoes that will last longer because they fit better. Retraction Footwear even has a vision for the end-of-life scenario — customers can return their unwanted thongs to the company, which is working to develop a recycling solution to turn old shoes into new filament. When it does, the circular economy loop will be complete for its product, enabling both sustainable production and consumption of these shoes.”

Can you 3D print eyeglasses?

Yes, and one study has found that 3D printed glasses have a higher wearing comfort, are more stable and sustainable than any other glasses. Source: EOS Conducts Sustainability Study for Eyewear Frames

Fitz Frames is a company that 3D prints eyewear with the mission to solve the problems with kids’ glasses: cost, time, fit and durability. Read more about the company’s use of additive manufacturing and augmented reality, and watch how Fitz Frames pivoted from eyewear to PPE in just ten days on this bonus quarantine episode of The Cool Parts Show.