The Rise of AM Factories, Metal 3D Printing, Machining Synergy and Favorite Stories from 2023: AM Radio #47

Additive Manufacturing Media editors reflect on the top 10 stories by pageviews and then share their favorites, regardless of ranking, in this podcast episode.

Share

In this last podcast episode of 2023, I asked my cohosts Pete Zelinski and Fiona Lawler to reflect back on our most-viewed stories for the year and also to share their favorite pieces. In reviewing the top 10 articles and videos by pageviews (find the complete list linked below), we discovered some interesting trends that seem to speak to additive manufacturing’s advance this year. In particular, we noted strong representation for metal 3D printing applications, a focus on postprocessing including machining, and reader interest in the “AM factory” model of contract manufacturers utilizing proprietary processes. Then in the second half of the show, we set the data aside and dig into our favorite stories, which run the gamut from build plate management to startup considerations to how the oil and gas industry is beginning to implement AM in its supply chain.

Transcript

Stephanie Hendrixson 00:05

For our last episode of the year we're looking back at our top stories our favorite stories and what they can maybe tell us about additive manufacturing in 2023. That's coming up on AM Radio.

Jodee McElfresh 00:26

AM Radio is a product of Additive Manufacturing Media. So are The Cool Parts Show, The BuildUp and Additive Manufacturing Magazine. Ready to be a part of the AM universe? Subscribe at AdditiveManufacturing.media today.

Stephanie Hendrixson 00:43

Welcome to AM Radio, the show where we tune into what's happening in additive manufacturing of Stephanie Hendrixson. And I'm joined in the studio today by Pete Zelinski.

Peter Zelinski 00:51

Hi Stephanie

Stephanie Hendrixson 00:52

and Fiona Lawler.

Fiona Lawler 00:53

Hi, Stephanie.

Stephanie Hendrixson 00:54

So this is our end of the year episode, for 2023. And historically, we have used the last episode of the year as kind of a top 10 list like looking back at our top 10 stories and talking about each one and trying to sort of come to conclusions about why they may be made the top 10. For this year, I want to do something a little bit different, we are still going to publish our list of Top 10 stories. These are the top 10 stories based on pageviews on our website, if you're listening to this right now go to the link in the show notes. You'll find that blog posts there and on our website AdditiveManufacturing.Media. But instead of going through each one, what I'd like to do is just kind of look at that list, list and talk about some of the trends and the themes that we see in it. See if we can draw any conclusions about additive manufacturing for this year. And then I've also asked you to come prepared with some of your favorite stories from the year regardless of how they ranked and we'll talk about that and in the second half. Sounds

Peter Zelinski 01:47

good. Do you want me to give a quick stab at trying to verbally summarize the top 10 list?

Stephanie Hendrixson 01:53

Yeah, let's start there.

Peter Zelinski 01:54

Okay, I'm going to go from 10 up to one and this is again, in terms of page views. Our top 10 stories of the year, we're about the additive manufacturing technology company and part maker Seurat the system they're producing, that was number 10. Number nine DMG MORI's system for building puck structures into build plates that make it downstream post processing via CNC machining much easier. Number eight, was a piece by Velo3D founder Benny Buller on challenges related to the advance of 3D printing for metal seven Collins Aerospace, why they're doing internal production of additive manufacturing as as opposed to relying on a supplier they're doing both but why they're they're leaning toward insourcing number six electroplating for polymer 3D printed parts. Number five Norsk Titanium, another additive part maker with a proprietary process, how they're scaling up. Number four, was a Cool Parts Show episode about a very large 3D printed boring tool cutting tool for big bores. Number three is a 101 piece exploring what is HIP, hot isostatic pressing. Number two is the way that machining and additive integrate at Keselowski Advanced Manufacturing. And the top story of the year by page views is our story about additive technology company and part producer Vulcanforms and their large scale production additive process. So that was really fast. And again, find a link in the show description to that list with links to all of those stories. But those were our top 10 stories. And yeah, looking through that I definitely see some themes. Where should we start?

Stephanie Hendrixson 03:48

So the first thing that strikes me, and I think it struck all of us as we looked at this list for the first time, we cover lots of different types of materials at Additive Manufacturing Media, we cover polymers, we cover ceramics, we cover composites. This list is almost entirely about metal 3D printing. And that's kind of interesting.

Peter Zelinski 04:06

I know definitely noticed that first time that's ever happened. 10 items, nine of them are solidly about metal. One of them is about Polymer, but it's about plating it with metal, right?

Stephanie Hendrixson 04:18

Yeah. How to put metal onto your polymer boards.

Fiona Lawler 04:20

I'm curious here, why our audience why our readers manufacturers are wanting to learn more about metal and I'm wondering what types of end use products they're looking to use this 3D printing process for?

Peter Zelinski 04:33

I think there are a few possibilities I see. So additive increasingly, the long arc of it being accepted into production, production processes that relate to metal parts, conventional production processes, leave openings for metal additive processes as metal additive gets better and better. And what I mean by that is metal parts, conventional processing they're made through forging or casting or machining. Well, production machining is typically lower batch size work, meaning it's a potential opportunity for additive to step in and perhaps realize a design improvement or a flexibility improvement. Meanwhile, casting and forging, increasingly, and almost always, we're seeing there is a lead time challenge associated with that process that additive can speak to. So plastics, it's not quite the same thing with plastics, there's a lead time challenge, only if you don't have the mold. Yet, if you're still waiting to produce a mold, then there's an opportunity for additive if you already have the mold, the lead time force injection molding is not necessarily long, you start making you start up and start making parts again. So it's not exactly the same. So I do see that window of opportunity for metal additive as metal additive gets better

Stephanie Hendrixson 06:06

and better and better trajectory, just looking at some of the companies that are mentioned in here. We've got Vulcanforms, we've got Norsk Titanium, we've got Seurat. These are all companies that are working on platforms that are meant to be more productive, their proprietary processes, that these companies are going to own and operate within their own facilities, with the goal of making lots and lots of metal parts. So like the technology is getting better. And clearly there's interest in these type of contract manufacturing companies, what we've called like a and factories that are going to provide this as a service. So I wonder if that's playing into it, too. So that's right.

Peter Zelinski 06:41

Like what you're picking up is why is there so much interest in metal additive as reflected in our top 10? Well, it's kind of been a year or a season for the advance of metal additive technology. There's a lot happening there. That's very interesting and moving the possibilities forward in a big way. I think maybe also, what I see reflected in this commonality among the top 10 is just where the energy of our audience interest is right now, there and I guess it relates to sort of this season of advance. But there were plenty of newcomers to polymer additive processes in past years past moments of time. We're in a time now where metal additive is drawing a lot more candidates and capturing a lot more attention of real emerging and potential users.

Fiona Lawler 07:36

Like you said, Stephanie with metal am progressing. They're also still challenges to overcome. And in the Velo3D piece by CEO Benny Buller, he talked about using metal AM for bigger volume production and being able to scale up when necessary.

Stephanie Hendrixson 07:53

So I think the point about challenges is important. And I think we see that also reflected in this list. So many of these stories have to do not with the 3D printing directly, but with stuff that you do to the parts after they're printed. So hipping electroplating, the DMG Mori story is about these build plate pucks that they use to machining. Yeah, it's about machining. And yeah, machining comes up in this list of bunch.

Peter Zelinski 08:17

That's really true. So your point, Fiona about the challenges, like, that's what I love about our coverage and the role we get to play because there are these wonderful future finding successes happening, but then there's also the need to temper it with reality about the challenge is still ahead and the challenges that users are still struggling with. But we've seen the point of challenge move. These stories in the top 10, to a large extent, are not about making the case for additive. The 3D printing process is accepted and a given. It's about just like you say, what comes next? What's the next challenge downstream after that, really that story about the big 3D printed cutting tool? within that organization that adopted that tool? Somebody had to be convinced that a strange, crazy 3D printed generative design like that that was the right choice. But that's the only story on that list that's like that. The rest is operations manufacturers are more familiar with and what is the right way to integrate with them with additive Fionna? You hinted at one more theme that I see in this list. So you talked about Benny Buller made the point that where this has to go is scaling up to higher volumes. We've done various stories this year about companies using proprietary processes to scale up to higher volumes. And in fact, we did a special issue of the magazine on that topic, the am factory concept. companies that choose to not be machine proof fighters, but instead take a proprietary technology and master it as a contract scale production metal 3D printing house, every single one of our feature stories that appeared in that special issue is on this top 10 list somewhere Vulcan formed Sahra and norsk titanium.

Stephanie Hendrixson 10:18

Yeah, and we have no way of measuring how many people flip through that print issue and read each of these stories in the physical magazine. But it's interesting that we put together that issue and that interest is also reflected in the digital pageviews.

Peter Zelinski 10:32

And it speaks in a different way to the challenge that end users are facing and even a type of question or type of answer to a question that is becoming distinct for additive. Additive adopters want parts and so the question is, what's the right way to get those parts? Do you invest in the machine yourself? Do you turn to a supplier and expect them to have or add additive capability. And now there is this third choice and largely a different choice, which involves the business flourishing around an altogether new unique, distinctive additive process and realizing the potential of that process. Alright,

Stephanie Hendrixson 11:17

I think we should take a break again, if you want to see this list of top 10 stories if you'd like to read them or learn more, that link will be in the show description. And we'll be right back after this.

Jodee McElfresh 11:31

This episode of AM Radio is brought to you by Additive Manufacturing Media, your source for the latest news and innovations in additive or industrial production. The editors of Additive Manufacturing Media report on am applications and additive manufacturing magazine, the buildup newsletter in The Cool Parts Show video series. Whether you're a successful additive manufacturer already or considering adoption, Additive Manufacturing Media will help you discover the latest and 3D printing technology and applications. Find all of our reporting industry news, educational webinars and more at additive manufacturing dot media, and Subscribe today to join the am universe.

Stephanie Hendrixson 12:15

And we're back. We've been talking about our top stories on Additive Manufacturing Media for 2023. In the second half of the show, we are going to now shift to talking about our favorite stories. So I've asked my cohosts to come prepared today with their favorite stories from the past year, which they themselves did not write. So Pete, let's start with you.

Peter Zelinski 12:35

Okay, couple favorites from the past year. The first one this story, the headline is United Performance Metals Is the One Stop Build Plate Shop for Production AM. Stephanie, you wrote this story. And it's about a company located not far from us united performance metals, and they have become a build plate supplier. They're the first business I'm aware of that is specializing in this product in this service. But laser powder bed fusion machines, they need build plates. And they're fairly simple objects. Except there's a lot of variety different machines have different build plate dimensions. And what United Performance Metals is willing to do is not only manufacture build plates for you, but also customize them for you if you need the them tailored to spec in some way, maybe a shorter Z height, for example. And also manage your refurbishment of your build plates. You can send the US ones back to them, they will make them smooth again and return them to you and just manage that ongoing inventory. Here's why this was so interesting to me. So first, they're serving additive manufacturing. But this is not an additive business. This is a machine shop, they're doing machining, we put it on the cover of the magazine. And I loved getting to put it on the cover of the magazine because it was a big step forward for us recognizing the advance of where our audience is heading. We do covers frequently, almost all the time that on some measure, we're saying Look what additive can do. This was a cover story that made the statement you're relying on additive. Here's how to do it more efficiently potentially. And so there's not even an additive machine on the cover. There was a Haas machining center on the cover making these build plates. I thought that was really cool. Your story mentions Chris Prue. He works for UPM he's Applications Development Manager on the way home from our event Formnext forum Austin held this summer I sat by him on the plane struck up conversation but he gives his name he names his company and I recognized him immediately because I keys famous In my mind from your article, I said, Oh, I know you, you guys are the build plate people. And he just he was over the moon about that he thought like, yeah, we want to be seen as the build plate people like that was that was a funny encounter. What I love is ultimately the statement that this story and this business makes about additive, which is very similar to other manufacturing processes that are mature and accepted. Other manufacturing processes have objects that you make for those processes, and only the people in those processes know them, machining uses tool holders, everybody who's in machining knows what this thing is and what it does. And if you're not in machining, it would be a little bit hard to explain to you what a tool holder is. But nevertheless, there are companies that do very good business serving machining by making and supplying toolholders. So similarly, the acceptance in advance of additive needs to generate businesses like that super niche products for these additive processes. And it was cool to see that that's happening for additive. What I'm curious about as I read this story again, and I think back about it, Stephanie, they are close to us. They're located geographically close, we're in the Cincinnati area, they roughly are two, we learned about this company originally, because it just so happened that the President of the United States made a visit there and gave a speech there. And it was all in the news. And it kind of got this company on our radar. And you connected with them, you went to see them. And I guess I'm wondering what was the impression and expectation you had of UPM based on that initial contact? And then how did you think or feel differently after you came out of there? Because I remember you becoming kind of an advocate for how cool what was happening at that facility?

Stephanie Hendrixson 16:59

Yeah, so I'm not sure what expectations I went in with like I thought their their value proposition was very interesting. Like we've just seen this increasing scale for metal 3D printing and the fact that now we need another business that can just handle the build plate side of it was super interesting to me. And I was just very curious to learn more, walking into their facility. It's a very large space, it's larger than what they need right now. But they have plenty of room to grow. It feels very much like a machine shop. Like there are grinders. On one side of the aisle, there are those Haas machining centers on the other side of the aisle, can just sort of follow the path that each of these build plates takes as it comes back to the facility to be resurfaced, or as it's being manufactured in the first place. What was really striking though, is that they have all of this shelving with just all of these different varieties of build plates, like I had never realized how many different sizes and shapes there are to go into different types of machines. And so we're walking through and Okay, these are the plates for the EOS M 400-4. Here are the plates for the Velo3D Sapphire platform, which are round. So they're kind of distinctive, and like as you're walking through, you just start to really appreciate what kind of variety exists in this otherwise really simple piece of the process that is so necessary, but so easily overlooked.

Peter Zelinski 18:19

Link to this story to all the stories we'll talk about in the show description, including pictures of some of that build plate variety that that you're talking about.

Stephanie Hendrixson 18:27

And I'm glad you picked this story because I do have a little bit of an update in that original piece. One of the sort of future plans that UPM had was to start offering other types of services. So eventually, like maybe finish machining for parts. One of the things that they mentioned was heat treat. And I actually ran into Chris Prue last week and they do have a heat treat furnace now so that piece of it has come to pass.

Peter Zelinski 18:49

Okay, another favorite story, Fiona, this one is yours. And the headline is 3D Printing Project to advance Medical Device Customization. This is your report on some work that involved a variety of different academic institutions University of Texas at Austin, Georgia Institute of Technology, Penn State University, the company actuated medical is part of it too. And what this work involves is it is 3D printing polymer, but with magnetic particulate infused all through the polymer form that's being made and the specific object application that they're thinking about is ventilation masks, and the way that these masks fit children in particular, they often don't fit well. And sometimes there are pressure related sores that result from that and a solution would be if there was a way to not just adjust the shape of the ventilation mask but also keep on adjusting it for Comfort and for just so it touches different surfaces of the patient by 3D printing these masks with this magnetic particulate potentially it creates built in handholds magnets could be used to reshape, distort, shift the placement of these masks on the patient and ultimately make them more effective and more wearable and more comfortable. It's really cool work because it's, it's not just solving a problem in a new way with 3D printing. But it's like thinking differently about 3D printing to another aspect of the work and just kind of maybe a secondary unexpected aspect that you got to talk about in the story. But there is a sociological aspect of it too. And actually a sociologist looking at this particular team, because as it happens, it is an all female team of researchers that's working on it, that is an aspect of it that on the one hand, like I feel like drawing attention to and on the other hand, I sort of wish we didn't draw attention to like it should if you you bring a group of people together in STEM, if they all happen to be one gender, or the other. Like that shouldn't necessarily be notable. But yeah, there's there's a researcher who's part of this team who's sort of studying the interaction among the team. So there are a lot of cool, interesting aspects of this story. And I guess like one other aspect of it that was gratifying for me to watch is, you are our newest team member. And at the date, we're recording this, we're looking forward to not far off your one year anniversary with us. And this is a story you pursued all on your own. And I learned all about it when I read your article for the first time. And that was that was pretty cool, too. So I guess here's the question I wouldn't mind you speaking to, we develop a lot of stories. And there are some that we give additional presents to by publishing them in our magazine. And there came the moment where this story seemed like a possibility for the magazine. But there were one or two hurdles we were still working out. And I just remember, you were really an advocate for this story. And like really wanted to see this one in print. So I guess I'd love to hear you say like, what really intrigued you or got you excited about this particular story, like what resonated with you?

Fiona Lawler 22:22

I think the reason I was so excited about this was because it was such a technical story. This was probably up until this point would this was my most technical story that I wrote, the story had so many moving parts, we talk about D fam and the story, we talk about different materials being experimented with this story. The manufacturing side, there's robotics involved, a really interesting 3D printing process with reactive extrusion. And then like you said, there's that social science aspect with the team being all female, and that being studied, and you know, that is something I'm happy you mentioned, because they were really proud of that. My source for the story, Carolyn Seepersad. She's one of the CO leaders on the project. And she was so proud of the fact that it was an all female team and how well they were working together. And I remember her saying, one thing that the social scientists noticed was that each of the CO leaders on this project has a set of graduate students helping them with the research and the social scientists said that it was really difficult to tell which group of students belonged with their corresponding co leader of the project just because everyone worked. So well together, questions were being answered by all participants in the project. And that was something that I thought was really cool. So it's really hard for me to choose just one story for each of you. But I will start with you, Pete. The title of the article is called Zeda Additive Manufacturing Facility Will Serve Medical, Military and Aerospace Production in Springdale, Ohio.

Fiona Lawler 23:56

Part of the reason I chose this was because yesterday, you got to attend the official opening of this facility. And a couple months back, I actually joined you on this site visit. So it seemed like this article had really come full circle. So that's part of the reason why I selected it. And one thing that I remember thinking to myself, Wow, this is so cool, is that there's medical, military, aerospace production all going on in one place. And the way that this facility was set up, this was one of those facilities that was built from the ground up. And I'm kind of circling back to a conversation I actually had with Stephanie in a recent AM Radio where we talked about different additive facilities. And this one is a really great example because they have a lot of other facilities that they were able to draw ideas from and best practices and what equipment to include and how best to lay out the floor plan. And I remember when I was there, there was just such a clear vision for what they wanted this to look like. So being that when we were last there together, it was still in the process of being set up. What Did you see yesterday with its completion?

Peter Zelinski 25:02

So that's right. So this is the Zeda additive manufacturing facility, Springdale, Ohio. It's also another facility not far from us as it happens. This is a business that is the merger of PrinterPrezz and Vertex Manufacturing both of them also relatively new businesses, but smaller businesses, additive companies that have come together. Yeah, and they're officially open for business. Now we saw their facility underway being set up, it still looks pretty airy and open now. And at the opening event I was at recently, there were a few places where there were easels with sign placards representing machines that were soon to be installed in that space. But the point you made about models to draw on and very specific vision about what equipment to use where and how to use it, that was really striking at this most recent visit and seeing the way that they're set up now because Zeda serves both aerospace and defense customers, and medical implant customers and the setup and even the business model is different for these different uses. So most of the facility by square foot is for space and defense related work. And this includes their two biggest machines are two of the larger size Velo 3D machines. They have other Vela 3D machines as well, they have additive machines from add up, they have equipment from EOS. And I'm probably forgetting something but they have plenty of additive equipment in addition to plenty of post processing equipment, de powdering equipment for large parts CNC machine tools, because it is for defense in particular, it's all located in one facility that obviously is on US soil. So they they clearly can offer us manufacturing in this facility and in fact very vertically integrated US manufacturing and and they have plenty of room to expand that and build that out more. Meanwhile, the medical implant business it's called Zeda health. And this business is concentrated within particular, walled off rooms in the facility, one for the additive work, one for quality and inspection. And one of the constituent businesses PrinterPrezz. So one of the founders of that business, Allen Dang, he was at the event I spoke to him and he pointed out Yeah, like our facility in Fremont, California, making medical implants like we saw, we thought it was so big, we thought we had so much but it just fits in that room. Xena is taking a building block approach, they call it a Lego block approach to how they design equip these facilities, these big rooms for making additive implants. And their business model is to replicate that facility in different parts of the world. Every region everywhere is struggling with supply chain to some degree and wants more localized manufacturing. And that is that is particularly valuable for medical implants. So a facility in Singapore or and one in Indonesia and one in Thailand, like they're thinking about locations like that very far removed parts of the world from where they are in the Cincinnati area. But places where they can drop in roughly the same process. They've already worked out and even own and protect the IP from Cincinnati while they enable manufacturing in a distant part of the world and that's the way they expect to expand. And a side bonus of that is the much of the work in the defense area is ITAR controlled and needs to be done by employees who are US citizens. Having these modular walled off additive implant facilities means in some cases, non US employees can be employed by the facility so long as their work is contained within that part of the business.

Fiona Lawler 29:30

My next article pic is one that was written by Stephanie and this title is Next-Gen Horse Trailers to Be Built with Robotic 3D Printing. So just in the title, it's like wow horse trailer you can 3D print that interesting. So I remember when Stephanie was originally talking about this article, and I just thought to myself how on earth do you print a horse trailer? That's that's huge, you know that it houses horses. And and the answer was large one I'm additive manufacturing. So I just wondered if you could talk a little bit about the company, Double D Trailers and how they got the idea to do this, because I'm just interested in learning more about this story.

Stephanie Hendrixson 30:09

So I have to say I'd have the same reaction that you did originally when I heard about this. And actually, listeners don't know this, but my dad is really big into trail riding and has has a trailer has a couple of horses. And he was the one who told me about this company originally, and was asking all kinds of questions, and I had no clue what he was asking about at that time. And then Double D Trailers independently found us and reached out. And that's kind of how the story came together. But basically, this company, originally, they were building the trailers themselves, they were manufacturing them, they were working with a with a supplier that was doing some of the fabrication for them. And they reached a point where neither of these companies really had enough work. And so they sort of agreed on this kind of split, where that manufacturer would take on all the fabrication and Double D has shifted into really focusing on designing trailers developing new features for them. And a lot of what they do is custom made trailers. So you would go to them and say, I need to haul three horses, I'm going to use such and such truck to do it, it needs to have these features, you know, I want living quarters, or I want a little tack bay or whatever it is, and Double D will come up with that design work with their supplier to get you that trailer. And so for them, 3D printing is super interesting, because it would be a way to just really quickly deliver on whatever the customer might want to order. So they're not having to deal with tooling, they're not having to, you know, think about how they're going to hold or fixture, the different pieces of the trailer as it's coming together, they'd be able to basically print the entire body of it just in one go. And they're really, really excited about this idea. And they've had a lot of success so far with the things that they're testing. They're still working on getting the right material, and all of that stuff. But it is a really interesting idea. And I think they are getting close to to really achieving it.

Fiona Lawler 31:56

It seems like fate, that you were meant to write the story that they reached out and but what strikes me is that they plan to print these enormous horse trailers in one go and one continuous print and obviously large format additive is necessary for that. But how are they how are they mixing robotics into this?

Stephanie Hendrixson 32:16

Well,so they've been working so far with this company called Loci Robotics, which has developed a large format printing platform, which is just one robot arm, I think it's on a on a track. So we can it has a pretty good range. But it can't right now make a full sized horse trailer. So they did successfully print a prototype with that platform, but it is it is scaled down. And so what they are working on now is identifying the right printing platform that can do that entire horse trailer body in one go. And what it probably looks like is two robots printing simultaneously, they would both be on tracks kind of sliding back and forth. And just working in tandem to be able to do this. What they're really trying to eliminate here is a whole lot of assembly a whole lot of labor. And their estimate right now is that if they had this system with the two robots, they could print one trailer in something like 15 hours, which is a huge time savings over having to you know cut and bend and then fabricate and weld like all of this steel together. They think they can really shorten their their lead times and also get all of those design benefits out of this do.

Fiona Lawler 33:21

I'm honestly really excited to see a working prototype for this. And I remember your article also mentioning some kind of fancier and more tricked out features like wasn't there air conditioning for the horses?

Stephanie Hendrixson 33:33

Yeah, so the thing about horse trailers today is they are typically not climate controlled. You have you have windows on the side. And like usually, the best practice is open the windows while you're driving down the road. So the horses get some some air. And in this 3D printed design, one of the things that actually people like on YouTube and on social media who've seen it have responded to is it has windows that open but they are meant to be kept closed while you're on the road. The reason for that is because they are intending as part of this printing process to actually build ductwork into the trailer itself. So not something that needs to be attached afterwards, something that's actually like printed into the walls. And simultaneously they're working on this whole Internet of Things solution for climate control, where there will be like a thermal camera inside the trailer that's pointed at the horses and if your horses start to overheat or they're getting too cold or something, there would be a system that kicks on to adjust the temperature to keep them comfortable to keep them safe and healthy.

Fiona Lawler 34:31

That's just really cool.

Stephanie Hendrixson 34:32

So thank you for asking about them.

Stephanie Hendrixson 34:35

Alright, so Pete my pick for my favorite story of yours for this year is called ConocoPhillips Sees Oil and Gas Supply Chain Opportunity with Additive Manufacturing. So this story is all about how this company ConocoPhillips is adopting additive manufacturing, for on demand locally made spare parts and the thing I didn't appreciate about oil and gas until reading this story like there's this great picture in In the piece that is just like this desolate looking landscape with this oil and gas facility in the middle of Alaska and like this is what parts of this industry look like they're your remote, you are operating really expensive, important equipment. And occasionally you need these spare parts. And so ConocoPhillips has found that additive manufacturing is a solution for just really quickly getting these things that they need. And some of which are not even all that complicated. The example that's in the article is something called a burger plug, which is really just like a solid Inconel cylinder, it's a really simple part, you would look at it and think, why can't you just machine that or get it through some other process. But the fact is, the lead times have gotten so long on this otherwise pretty simple part that actually additive manufacturing is the way to make it. And this story I thought was so interesting, because we've talked a lot about medical, we've talked about aerospace a lot in terms of the ways that additive manufacturing is getting used. And here's this other industry that we haven't covered all that much. But it's just sitting here with these opportunities with these problems that additive can really easily solve. These are parts that are not made in huge quantities, they're not needed in extremely large batch sizes, you can sort of make them as you need them. And additive is just the perfect fit for that. And so I really enjoyed the story for the ways that it looks not only at how additive could solve this problem, but also deals with some of the realities of the standards and like how you get an industry to accept that these parts are going to be okay. The question I want to ask you about this story is first, how did you find this? How did this lead come to you? And then secondly, like what were the things that you learned about oil and gas in having having this conversation?

Peter Zelinski 36:46

Really glad you asked that first part about where the lead came from? I wasn't expecting that. But it's sort of interesting. It came out of the blue. Big Metal Additive president Slade Gardner emailed me and this is a person I've certainly spoken with and speak to from time to time, but not a whole lot. And yeah, just heard from him out of the blue. He's familiar with the work we do and what we're interested in. And he said, Pete, you just got to meet this guy, Carlo de Bernardi, who's the additive manufacturing lead at ConocoPhillips. And I responded basically, yeah, I'm game and Carlo and I put a an initial conversation on the calendar, it was just kind of an open discussion. But before we go any farther, Slade Gardner, thank you. Thank you for that introduction. What's really neat about the ConocoPhillips application, and okay, what I learned about oil and gas is just how gigantic their supply chain challenge is, and how expensive it is. So right that remote photo from Alaska, like that's where oil and gas work is done. It is a business that is inherently about going to where the oil is, which is almost always remote and inaccessible places. And the work is difficult. It's hard on equipment, they wear out lots of parts. And so the manufacturing that supports this process is to keep the process going by continually replacing parts. So it means delivering components to these remote and distant parts of the world with just the right timing so that everything keeps humming and and how does the oil and gas industry deal with that it's with tons of inventory. Some of these parts have long, long lead times in addition to the potentially long shipping times to where they have to go. And so tons of inventory billions of dollars of inventory for the oil and gas industry. We've talked about medical, we've talked about aerospace, these are thriving sectors with additive manufacturing. And I'm seeing oil and gas as the up and comer. But we're thinking about different things. We're not thinking about DFAM so much. We're not thinking about assembly consolidation, so much we're thinking about responsiveness. And Carlos got a long way to go. But he's trying to build that supply chain for for oil and gas for ConocoPhillips. The dream is you're not storing things in inventory anymore. You've got additive manufacturing nodes facilities close enough to these distant locations that they can print the parts as needed pretty accessibly. And standards are the beginning of that. And Carlo sees that very readily. And part of his job in the last couple of years has been to be very active in relevant standards bodies to allow components to be certified to his industries norms that were made through a different process. So that, for example, that burner plug that might once have been forged and or machined. Now it could be 3D printed. And there's still a shared language and set of requirements in place where everybody can agree that that plug will still do the job. And that's happening that's happening. He has been, there have been a lot of people involved, but he has been instrumental in getting additive manufacturing oil and gas standards created.

Stephanie Hendrixson 40:24

And Carlo has this great quote in the in the piece to that effect. He says you need to know the rules before you can change the rules. And like that stuck in my mind from the moment I first read this story. And you mentioned the interaction with Chris Prue on on the plane earlier. And that just reminds me I met Carlo at at Formnext forum, Austin and I had my own like little fan girl moment. And then he spoke at the conference. And it was great to just hear more from him about how the company is thinking about this and the gains that they're making in bringing additive into oil and gas and why.

Stephanie Hendrixson 40:56

Alright, so my favorite story from Fiona this year is called Six Considerations When Launching an Additive Startup. This was actually based on the very first site visit that we did together. And I think Fiona your very first site visit to an additive manufacturing facility, it was yes, so we went to this is another local story. It's kind of funny how a lot of these ended up being within driving distance of Cincinnati. But we visited this company called OMG Additive. It's basically one employee who started the company who owns the company, his name is JP Kinerk. And he had reached out to me sometime last year, just with this idea, you know, I'm really interested in additive manufacturing, I'd like to talk about, you know, maybe what type of equipment I should look into what types of business opportunities might be out there. And he acted so fast, actually, by the time we got around to having that conversation, he had already placed an order for a Multi Jet Fusion printer from HP. And so I had just been in communication with him. I knew he was local. And Fiona you and I went out there and saw his facility and talked to him about that. And you wrote this story. And so the gist of the story is the sort of six points that he shared with us in the course of that conversation, just about what are the things you should think about when you're starting a business based on additive manufacturing. And a lot of these were things that we don't typically have a chance to really talk about or write about. So it was things like how do you think about funding your equipment? What are the details around your facility that you need to think about? Like, for instance, what sort of power might you need to power your equipment? How can you use different web services to sort of fill your machine capacity while you're still trying to build a network of local customers. And the reason I like this story so much is there are plenty of cases that we encounter where there is an established manufacturing company and established OEM that wants to adopt additive. And so they figure out ways of bringing it into the fold, incorporating it into their existing processes into their existing facilities. And those are really powerful and important stories that we get to tell. But on the other hand, there are also these instances of these entrepreneurs and these inventors and these people that are like JP, that aren't coming from the manufacturing world currently, that's not their current job or their or their day job. But they are excited about the technology, they want to make something they want to create their own invention and sell it or they just want to make things for other people like in his case. And additive is the easiest way for someone like that to become a manufacturer. And I love getting to tell stories like those I love getting to read stories like those that are that are written by other people. So Fiona, I'm just curious, looking back on the story, looking back into your very first site visit, what did you expect going in? And what do you remember being surprised or interested in when we got there?

Fiona Lawler 43:46

Honestly, I didn't know what to expect, because I had never really seen an additive space for myself. But I think this was the perfect first site visit for me because here's someone who was also learning additive, just as I am. I really liked that you talked about that anyone can become an additive manufacturer, because it's a learning process. And it's a learning process that a lot of people are excited about like JP and one thing he talked a lot about was how networking helped him kind of break into this space, how people in additive are just very willing and open and honest to talk about their experiences and how he formed some connections that gave him advice for starting his own business. And now how he's paying it forward by sharing, you know, these tips with us, for our audience for our readers. So I think that process, that learning process, the willingness to learn, is kind of saw that come full circle with this story.

Stephanie Hendrixson 44:40

Yeah, that was something I appreciated about the story and about the site visit like he was just very open with the challenges that he's faced and the ways that he's figured out to overcome them and I didn't really know this going into it, but it did turn out to be a pretty good first site visit for a new writer as well like getting to learn from somebody who is also actively discovering and Finding out how to do this.

Stephanie Hendrixson 45:01

Alright, I think we'll leave it there if you want to see our top 10 stories for the year. If you'd like to learn more about any of our favorite stories that we've mentioned, those links will be in the show notes. This is our last episode for 2023. So stay tuned, we'll be back in 2024. Make sure to subscribe so you'll get notified when we are back with new episodes. And in the meantime, give us a five star rating share the podcast with somebody and this is episode 47. So we have a back catalogue of 46 other episodes dealing with lots of different topics and additive manufacturing that you can check out in the meantime, we'll be back soon. Thanks for listening.

Fiona Lawler 45:38

AM Radio is recorded with help from Austin Grogan. The show is edited by Jodee McElfresh and Stephanie Hendrixson and our artwork is by Kate Schrand. AM Radio and Additive Manufacturing Media are products of Gardner Business Media, located in Cincinnati, Ohio. I'm Fiona Lawler. Thanks for listening.

Related Content

-

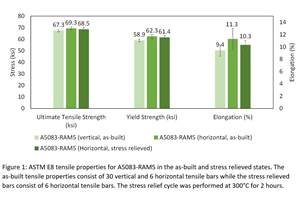

Elementum 3D’s High-Strength Aluminum Alloy Eliminates Need for Heat Treatment

Elementum 3D’s A5083-RAM5 aluminum alloy enables manufacturers to print advanced components from a high-strength aluminum alloy with reduced postprocessing time and cost.

-

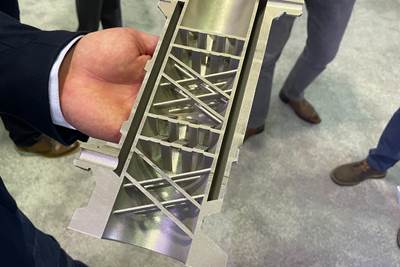

3D Printed Inconel Sleeve Protects Critical Valves from Thermal Shock

Valve manufacturer Velan has developed a double-walled sleeve using lattices as thermal insulation to protect critical severe service valves from thermal shock and stress.

-

Digital Manufacturer Partners With Maritime, Offshore Specialist for MENA Regional Expansion

Immensa will serve as the exclusive distributor within the maritime and offshore sectors for Pelagus 3D’s products in the Middle East and North Africa region, and act as the exclusive service provider for projects initiated through Pelagus 3D’s platform in the territory.

Related Content

Elementum 3D’s High-Strength Aluminum Alloy Eliminates Need for Heat Treatment

Elementum 3D’s A5083-RAM5 aluminum alloy enables manufacturers to print advanced components from a high-strength aluminum alloy with reduced postprocessing time and cost.

Read More3D Printed Inconel Sleeve Protects Critical Valves from Thermal Shock

Valve manufacturer Velan has developed a double-walled sleeve using lattices as thermal insulation to protect critical severe service valves from thermal shock and stress.

Read MoreDigital Manufacturer Partners With Maritime, Offshore Specialist for MENA Regional Expansion

Immensa will serve as the exclusive distributor within the maritime and offshore sectors for Pelagus 3D’s products in the Middle East and North Africa region, and act as the exclusive service provider for projects initiated through Pelagus 3D’s platform in the territory.

Read MoreBaker Hughes Successfully Implements Oqton Manufacturing OS System to Optimize Additive-Driven Manufacturing Workflow

3D Systems say this successful implementation demonstrates its Oqton Manufacturing OS’ ability to accelerate the design and production of additively manufactured parts across the entire manufacturing workflow to increase efficiency and facilitate regulatory compliance.

Read MoreRead Next

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MoreTop 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

Read MoreFor Velo3D CEO, the Future of Metal AM Is Large Producers

The growing demand for metal part production via additive manufacturing will be met by producers that start small and massively scale, says Velo3D’s Benny Buller. Thus, AM will follow a different path from other part-making technologies.

Read More

.jpg;width=70;height=70;mode=crop)