Additive Manufacturing at NASA (Part 2): AM Radio #52

In this follow-up podcast episode on additive manufacturing at NASA, Dr. Tim Simpson joins us to discuss how the organization thinks about AM overall, and its role in advancing additive alongside and in service of commercial industry.

Share

In this follow-up to episode #51 of AM Radio, Dr. Tim Simpson joins Stephanie Hendrixson and Pete Zelinski in the studio to talk more about how NASA is implementing and shaping additive manufacturing. As part of an intergovernmental personnel act (IPA) assignment, Dr. Simpson has spent the last two years deployed within NASA helping to advance additive use cases and connect AM users within the organization. In this episode, he shares insights from this work including NASA's collaborative relationship with commercial space; its role in studying AM fundamentals and providing testing resources; missions currently using the technology; and where additive will enable NASA to go next.

Listen to this podcast episode embedded above or, if you haven’t heard it yet, find Part 1 linked below:

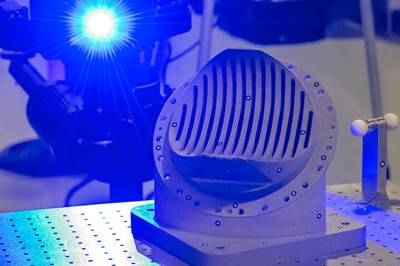

This 3D printed heat exchanger (referenced in the episode) was made for the Mars Oxygen In-situ Resource Utilization Experiment (MOXIE), one of the instruments on the Perseverance Mars rover. Martian air is carried into channels within this part to be preheated before conversion into oxygen. Source: NASA/JPL-Caltech

Transcript

Coming soon

Related Content

-

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

-

Inspection Method to Increase Confidence in Laser Powder Bed Fusion

Researchers developed a machine learning framework for identifying flaws in 3D printed products using sensor data gathered simultaneously with production, saving time and money while maintaining comparable accuracy to traditional post-inspection. The approach, developed in partnership with aerospace and defense company RTX, utilizes a machine learning algorithm trained on CT scans to identify flaws in printed products.

-

AIM3D Study Shows 3D Printing Ultem 9085 Pellets Offers Lower Cost, Higher Tensile Strength

The material qualification testing indicates many benefits of creating components with AIM3D’s ExAM 510 printer using the composite extrusion modeling process, which uses standard pellets rather than the more expensive filaments required by other platforms.

Related Content

Velo3D Founder on the 3 Biggest Challenges of 3D Printing Metal Parts

Velo3D CEO and founder Benny Buller offers this perspective on cost, qualification and ease of development as they apply to the progress of AM adoption in the future.

Read MoreInspection Method to Increase Confidence in Laser Powder Bed Fusion

Researchers developed a machine learning framework for identifying flaws in 3D printed products using sensor data gathered simultaneously with production, saving time and money while maintaining comparable accuracy to traditional post-inspection. The approach, developed in partnership with aerospace and defense company RTX, utilizes a machine learning algorithm trained on CT scans to identify flaws in printed products.

Read MoreAIM3D Study Shows 3D Printing Ultem 9085 Pellets Offers Lower Cost, Higher Tensile Strength

The material qualification testing indicates many benefits of creating components with AIM3D’s ExAM 510 printer using the composite extrusion modeling process, which uses standard pellets rather than the more expensive filaments required by other platforms.

Read MoreDyndrite, MIMO Technik, Astro Collaborate on Machine, Material Qualification for 3D Metal Printing

The companies chose to collaborate on the development of the Mastro process in order to streamline and automate a closed-loop source for additive production and qualification.

Read MoreRead Next

Additive Manufacturing at NASA (Part 1): AM Radio #51

In this first episode of a two-part special on additive manufacturing at NASA, we discuss three specific 3D printed parts for upcoming missions and share observations about the organization’s approach to AM.

Read MoreAdditive Manufacturing in Space: Failing Upward

Not all 3D printed parts destined for space need to adhere to the standards of human space flight. Yet all parts made for space programs require some type of qualification and certification. NASA and The Barnes Global Advisors explore Q&C for these parts.

Read More3D Printed "Evolved Structures" for NASA Exoplanet Balloon Mission: The Cool Parts Show #61

Generative design creates stiff, lightweight brackets for EXCITE mission monitoring planets orbiting other stars. The Cool Parts Show visits Goddard Space Flight Center.

Read More

.jpg;width=70;height=70;mode=crop)