3 Examples of How Polymer 3D Printing Is Still Advancing in Important Ways: AM Radio #16B

On AM Radio, a conversation about ways the basic operation and capabilities of additive manufacturing with plastics is still changing.

Share

Innovators are not yet done developing all the capabilities of 3D printers or all the ways polymer additive manufacturing might work. The most recent episode of the AM Radio podcast focuses on plastics. As part of that episode, Julia Hider and I talked about three areas of recent advance that show how polymer 3D printing is still becoming more capable. They include:

Transcript

#1: Variable Layer Width

Peter Zelinski

All right. Welcome back. We’re talking about 3D printing for plastics. And before the break, Julia was telling us about her trip to the Plastics Technology Expo, the additive presence she saw there, which mostly related to tooling. We talked about all kinds of ways that additive manufacturing is is making tooling more effectively expanding the options for tooling. I want to stick with our plastics theme, Julia. There’s some stuff I’ve gotten interested in related to 3D printing for plastics, stuff I want to talk about, about the ways machine capabilities are changing. Yeah, let’s do it. Okay, one thing I’m really interested in controllable layer with in FDM, or fused filament fabrication, FFF, that style of 3D printing, getting to control and vary the layer width as you go during the build. This isn’t on the market yet. And I saw this for the first time at Formnext. Company, a startup in Belgium called Sculpman is developing technology for this. It is a controllable nozzle where the width is controllable and the width varies as you go as like another controllable axis of the 3D printing process.

Julia Hider

So yeah, this is something that kind of seems like a simple idea at first, but then the more you think about it, it becomes really complicated, just the slicing software would be totally different. And the machine is having to adjust this — the nozzle changes. So you know, what changes to the machine did the company have to make?

Peter Zelinski

So yeah, inventing the nozzle was part of it. And maybe not even the biggest part of it because of what you’re alluding to there, the complexity of this. So the nozzle is kind of rectangle shaped, it is rectangle shaped, and the width of that rectangle opens and closes as you vary the width. But yeah, the slicer software gets way different. Once you start to do that, to the extent they had to invent their own software as an aid to this nozzle. And so yeah, the nozzle width is controllable. So there’s, there’s that, but then because the nozzle is rectangular, like you’re not laying down spaghetti anymore. You’re — so you have to sort of keep that rectangle always perpendicular to the path. So, there’s a directionality to the nozzle that there wasn’t before — the software accounts for that. And then in addition, if you think about it, the cross-sectional area of the nozzle changes if it gets wider, but you need to keep the layer height the same. That means what the extruder is doing, how much it’s putting out has to vary in perfect synchronization with that nozzle opening up. And so that’s another part of the control. And the software takes care of all of that. Yeah.

Julia Hider

And then something else that your article mentioned is that this can reduce build time by a lot. There was a picture of a 3D printed part made on one of these machines, and you said that it would have taken 10 times longer on a traditional printer. That’s a significant difference. So, how does that work?

Peter Zelinski

Yeah, the time savings, like that’s what this is all about. And yeah, we do have an article about that. We’ll link this also in the show description. There’s a video in there, video I shot at Formnext. But the time savings is, is the real benefit of this. And why does it save time because it saves the back and forth. Otherwise, to fill in the area of a particular layer, like if that area is bigger than the width of the spaghetti noodle that you’re laying down, then you have to go back and forth and put in lots of spaghetti noodles, all these spaghetti noodles in parallel. And that’s a lot of machine motion. And really, that’s where the time cost of 3D printing of, of deposition 3D printing is, it is in the back-and-forth machine motion. If it’s possible just to widen the nozzle so that the deposition is always the perfect width of the area you’re trying to fill in then, like, yeah, you could have one pass covering even a sheep, where the profile varies all throughout the layer. And, and yeah, there’s part examples, pretty relatable part examples, that Sculpman’s able to show where the time savings for 3D printing is dramatic.

That’s a really interesting example. So, what else did you want to talk about?

#2: Variable Layer Height

Peter Zelinski

Sure, okay, very related. So, we just talked about variable layer width. There are important developments being made also in the area of variable layer height. Controlling the output of the extruder as a precisely controllable axis so that your layers don’t have to be parallel. Because if you think about it, like if you can gradually increase the output of the extruder, again, we’re still in FFF, if you can gradually increase the output of the extruder as you’re going through the layer, then you could get like a wedge-shaped layer of material. And one layer doesn’t have to be exactly parallel to the layer underneath it.

Julia Hider

Yeah so, do you have examples of when this feature might be useful?

Peter Zelinski

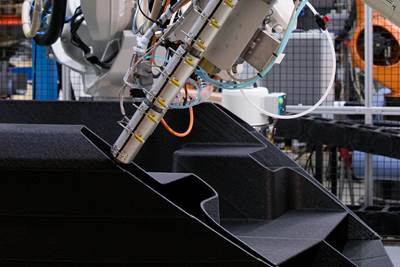

Exactly. And so, maybe that’s not totally intuitive. But the answer is robots. We love robots. So the thing is, if you’re going to 3D print with a robot, you want to take advantage of the robot’s range of motion and the ability to, to print in different planes, different directions. So there’s a company we’ve covered recently — that article also linked in the show description — Adaxis. It’s a startup. The founders are French and Swedish. And they’re developing software to make it way, way, way easier to convert a CAD model into a 3D printing program for any robot. They’re working with a bunch of different CAD geometries, CAD software. They’re working with various different robot makers and they’re trying to knit this together, but part of what they’re incorporating and trying to build in is this controllable extruder output, so that the layers don’t have to be just like 2.5-D constructs of parallel layer stacked on top of parallel layer.

Julia Hider

So, when you’re talking about robots, my mind sort of goes to DED. So, I know this is an episode about plastics. But could this technology extend to metal as well?

Peter Zelinski

That’s a good question. I think Adaxis would say, yes, they’re not trying to offer a robot 3D printing for any particular material or application. They’re trying to, like, really simplify the programming aspect of it. Their development has focused on putting plastic extruders on onto robots, but put metal deposition onto a robot, could you do that instead? Now, it gets a little different because it’s not an extruder that you’re controlling there. It’s welding of some sort, and you’re trying to control the amount of deposited material in welding — that would probably be a different control challenge. But that control challenge is no doubt masterable, as well. So yeah, you could get these metal shapes, also in which the form goes in various directions. And you can do intricate geometries where you don’t have to, like, stair-step the layers because your layer parallelism doesn’t match perfectly with the shape you’re trying to get. Like, what I think all this is about, and I guess why this is so interesting to me is, we’re still developing 3D printers. We’re still figuring out how to make these machines. There’s not yet enough axes of control to let you do everything you want to do. And we’re still figuring out all the different things that we could bring under control, precision over a nozzle width precision over extruder output, material deposition, like, these are all there’s all kinds of opportunities to come as we master these things.

So, we talked about metal in our plastics episode. Now, let’s take it back to plastics. So, you have one more thing that you wanted to talk about?

#3: “Vatless” Vat Polymerization

Peter Zelinski

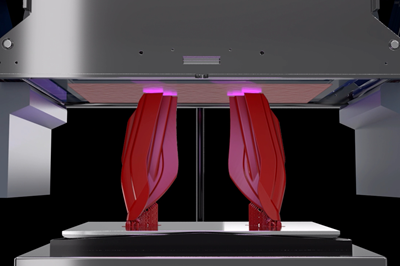

So, I do. Another way that how the machines work, how the processes work is fundamentally changing. So really interesting, the company is BCN3D, they’re based in Spain. And they’ve developed this vat polymerization process where there’s not a vat. Vat polymerization — solidifying resin within a vat layer by layer by layer with light projections that are the shape of the layer. BCN3D, they’ve gotten this process outside of the vat, like there is vats of material at either side of the build, but the build doesn’t happen there. And they’ve got this laminate that sort of bridges across, and a film of the resin sticks to the laminate goes across the part just long enough for the light to hit it, solidify the layer and then the laminate goes back and picks up another film that comes back out. And so, it is a different kind of 3D printing process that, that gets around the obstacles of vat polymerization, one of which is — okay, a couple of which are until now, the dimensions of what you’re building have to be contained with within the resin vat. No longer true in this process. And also, vat polymerization has been limited to relatively low viscosity materials because you need a resin fluid that’s going to quickly fill in the space that’s opening up as each layer is solidified. This doesn’t have that challenge. And so this process, you can use much more viscous resins, which just dramatically opens up the material possibilities.

Julia Hider

Yeah, that reminds me of a company I wrote about last year called Inkbit, but instead of doing vat polymerization, they do material jetting, and they’re also working on a way to work with more viscous polymers. And the more viscous polymers tend to have better or more desirable properties, but it’s difficult to use them in material jetting, because it’s hard to predict how they’ll flow as they’re being jetted. So Inkbit’s solution is to scan every layer of the print and use AI to see how the material is behaving. So it can adjust subsequent layers to compensate and then eventually predict how the material is going to move as it’s being jetted.

Peter Zelinski

So, that’s right. Like, I remember that the Inkbit article — like, another example of this is how for additive to keep on realizing its promise in production. It’s got to make use of the full range of materials in plastics. That means viscous materials, and yeah, so Inkbit offered another solution for how they’re bringing viscous materials into 3D printing. BCN3D now has their own idea, too, how to get viscosity into additive.

Julia Hider

So, I guess my question is, you know, where does this fit in the whole big picture of additive manufacturing? You know, you have seven generally accepted types of additive manufacturing, and one of them is vat polymerization. So, where does vat-less vat polymerization fit into this picture?

Peter Zelinski

So right, and it’s like, it’s semantics. And it’s kind of a terminology question, but it’s, like, a useful question. So, those seven generally accepted types that relates to a classification document that ASTM put out, American Society of Testing and Materials. And it’s super useful. And we actually use those categories in our organization of our, like, our supplier listings on AdditiveManufacturing.Media. But, it is possible that that classification was issued too soon because we continue to see processes and machines that don’t fit really well with one of those seven types. The Mantle process we mentioned in the first half of the show, maybe is an example of that. What BCN3D is doing, yeah, another example. So, is this vat polymerization? Well, the polymerization isn’t in the vat. So I’m not sure it fits. Like, you could argue just as much this is a deposition process because the material is being brought to the incomplete part and being added to it, deposited onto it. So yeah, this is a process that depending on which eye you wanted to look at it through could fit either of these categories. Maybe there’s a future coming where our taxonomy of different 3D printing processes expands or adapts to where the additive technology ultimately lands.

Julia Hider

All right, now that we’ve, you know, we’re questioning everything that we know about additive manufacturing, I think it’s a good place to wrap up this episode.

Peter Zelinski

Yeah, let’s get out before we break any more paradigms.

Julia Hider

All right, that’s it for today’s show. If you liked the podcast, make sure you subscribe, so you can see when we put out a new episode, like us and give us a five-star rating.

Peter Zelinski

Yeah, we love the five stars. Thanks for listening.

Julia Hider

AM Radio is recorded with help from Austin Grogan. The show was edited by Alex Lytle and Stephanie Hendrixson. Our artwork is by Kate Bilberry. AM Radio and Additive Manufacturing Media are products of Gardner Business Media located in Cincinnati, Ohio. I’m Julia Hider. Thanks for listening.

Related Content

-

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Related Content

Copper, New Metal Printing Processes, Upgrades Based on Software and More from Formnext 2023: AM Radio #46

Formnext 2023 showed that additive manufacturing may be maturing, but it is certainly not stagnant. In this episode, we dive into observations around technology enhancements, new processes and materials, robots, sustainability and more trends from the show.

Read More3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

Read More3D Printing with Plastic Pellets – What You Need to Know

A few 3D printers today are capable of working directly with resin pellets for feedstock. That brings extreme flexibility in material options, but also requires greater knowledge of how to best process any given resin. Here’s how FGF machine maker JuggerBot 3D addresses both the printing technology and the process know-how.

Read MoreQ&A With Align EVP: Why the Invisalign Manufacturer Acquired Cubicure, and the Future of Personalized Orthodontics

Align Technology produces nearly 1 million unique aligner parts per day. Its acquisition of technology supplier Cubicure in January supports demand for 3D printed tooling and direct printed orthodontic devices at mass scale.

Read MoreRead Next

Faster FFF Build Rate Using Rectangular, Variable-Orifice Nozzle (Includes Video)

A new nozzle design plus sophisticated slicer software offer control over layer width in polymer 3D printing while the layer height stays constant.

Read MoreFrom BCN3D, Lithography 3D Printing With No Vat Brings Bigger Scale Plus Viscous Materials

Parts take shape in the open air. Viscous resin is rapidly carried on a laminate to build each layer. LCD screen size, not vat size, is the limit on productivity.

Read MoreThis Company Is Developing Software to Make Any Industrial Robot Into a 3D Printer

Do robots offer additive manufacturing capacity just waiting to be unboxed?

Read More