Prototyping

The Benefits of Vertically Integrating Metal 3D Printing and Machining

Having 3D printing and machining within one organization enables Addman’s engineers to collaborate and consolidate so it can quickly make successful metal 3D printed parts.

Read MoreHP’s 3D HR PA 12 S Polymer Material Creates Smooth Finishes for Cost-Efficient Parts Production

The material can be used to create smooth surface finishes, which enables an optimized production process that streamlines postprocessing steps, thereby saving time and further reducing costs for producing complex smooth parts.

Read MoreContinuum Powders Creates Energy Partnerships With Priority Power and AirGas

Continuum is contracting to secure some of the industry’s greenest sources for power and argon gas. When the entire combination of the new renewable energy sources are added with its proprietary process, the company anticipates a total energy consumption of nearly zero.

Read MoreRoss Offers Expertly Reconditioned DPM-4-gallon Double Planetary Mixers

Ross also offers services for companies that have older Ross mixers and are interested in having the existing equipment reconditioned.

Read MoreIn "Hybrid" FIM Process, 3D Printing Complements Injection Molding

In a recent case study, Alpine Advanced Materials partnered with Nexa3D to produce 3D printed tooling for injection molded composites. Utilizing Nexa3D’s XiP desktop 3D printer and its Freeform Injection Molding process, Alpine was able to reduce prototype tooling production time and cost alike for its customers.

Read More7 Important Ideas on Postprocessing in AM

Additive manufacturing is defined by 3D printing, but it is more than this step. For almost every AM production part, steps after the 3D printing operation are essential to complete the part and realize its value. Here are several thoughts.

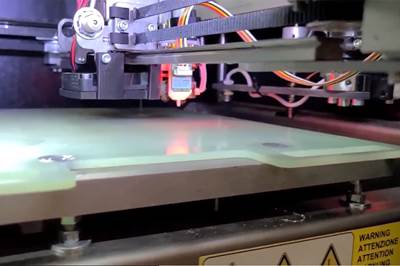

Read MoreOnAdditive Offers Aftermarket Upgrade for 3ntr A2, A4 3D Printers

The enhanced capabilities include a new control system that gives the printers increased printing speeds, improved quality, automatic bed leveling and various other user-centric improvements.

Read MoreHawk Ridge Systems and DyeMansion Forge Partnership to Integrate Software and Hardware in Additive Manufacturing Workflow

Collaboration creates a one-stop-shop for all the tools and software needed to create precision products that look, feel and function properly. Now, Hawk Ridge Systems’ integrated solution portfolio will include a complete print-to-product workflow with DyeMansion’s Powershot C, Powershot S, DM60 and Powerfuse S postprocessing solutions.

Read MoreGardner Business Media Introduces New Editorial Roles Covering Robots and Sustainability

Julia Hider is named correspondent for robots and autonomy, while Hannah Mason is named correspondent for sustainability in manufacturing, with both writers reporting on those topics across the Gardner Business Media brands.

Read More