Nexus, Hexagon's Digital Reality Platform Offers Collaboration Solutions Congruent With AM Needs

Nexus, Hexagon’s open, digital reality platform, enables collaboration among manufacturers and promotes the freedom to innovate using an array of digitalized tools.

More than any other manufacturing process, additive manufacturing (AM) demands collaboration among stakeholders concerning part design, production, operations and quality. Hexagon Manufacturing Intelligence (Hexagon), a company specializing in digital reality solutions, recently unveiled Nexus, a digital platform providing manufacturers a cohesive space to collaborate for optimized innovation and the more successful use of AM.

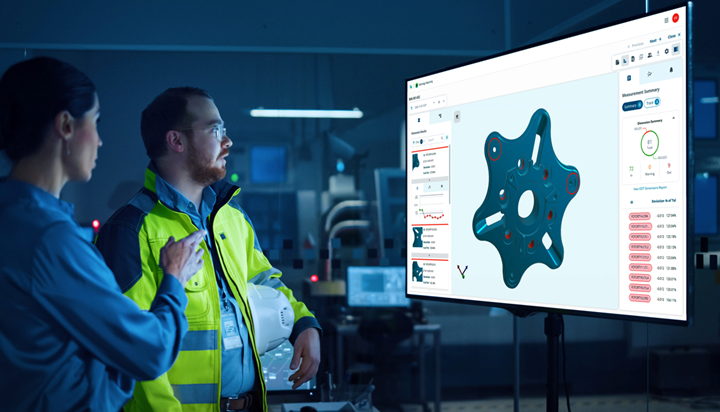

Nexus Metrology Reporting app depicted in real-time use for its collaboration and presentation capabilities. Photo credit: Hexagon

I attended Hexagon’s virtual launch event detailing the new platform. According to the company, its aim for Nexus is to foster an open platform complete with digital resources to connect equipment, data and processes for real-time distribution across product lifecycles. By addressing design and manufacturing issues in an accessible and accelerated manner, Hexagon hopes to assist otherwise siloed teams in strengthening collaborative resources.

The resources Nexus provides are housed in a cloud-based platform. Ready-to-use designs and engineering, production and metrology software applications reside in the Nexus portfolio for customers to pick and choose the technology best suited to their needs.

Inside the Tech Hub

At present, Nexus has developed four readily available, digital solutions (in the form of apps) to benefit AM as well as other manufacturing operations. They are:

The Nexus Metrology Reporting app captured using data sharing abilities via trend plot. Photo credit: Hexagon

- Metrology Reporting: This third-party app focuses primarily on the measurement of data. Hexagon says the app grants companies immediate access to reports on quality control data (using any chosen mode of equipment) to view trends and detect discrepancies. Manufacturers can create interactive, CAD-based reports to compile trend plots, compliance documents, and real-time data to share among team members along with other manufacturers.

- Materials Connect: This app functions as a cloud-based library complete with material data offerings for manufacturers to not only manage material information but also add material test data as it becomes available. This further extends in assisting behavior models when customers utilize Computer Aided Engineering (CAE) workflows.

- Materials Enrich: Employing machine learning capabilities and material behavior simulations, the third Nexus app offers users their preference when selecting optimal project materials. Before selection, the chosen material may or may not have been previously measured or experimented with. The app provides customers the ability to digitally test and brainstorm (with an array of material options) to obtain potential outcomes before committing blindly. Hexagon says the goal for this app is to improve material performance, lessen material waste and ensure long-term product sustainability.

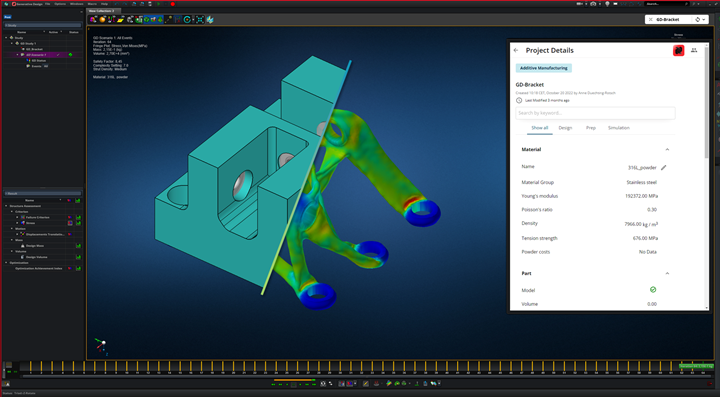

- Design for Additive Manufacturing (DFAM): This solution directly services AM. The app promotes effective collaboration when developing metal 3D printed parts. Currently, the pre-figured solution prepares prints that use laser powder bed fusion process. This app’s interface connects Hexagon’s multiple DFAM-related software programs via the cloud, to easily manage additive projects and connect members of different teams. The app aims to advance build design and geometry for more effective AM.

Nexus’ DFAM app digitally maps and generates designs with complex geometries suited to AM. Photo credit: Hexagon

Related Content

-

This Drone Bird with 3D Printed Parts Mimics a Peregrine Falcon: The Cool Parts Show #66

The Drone Bird Company has developed aircraft that mimic birds of prey to scare off problem birds. The drones feature 3D printed fuselages made by Parts on Demand from ALM materials.

-

How Machining Makes AM Successful for Innovative 3D Manufacturing

Connections between metal 3D printing and CNC machining serve the Indiana manufacturer in many ways. One connection is customer conversations that resemble a machining job shop. Here is a look at a small company that has advanced quickly to become a thriving additive manufacturing part producer.

-

At General Atomics, Do Unmanned Aerial Systems Reveal the Future of Aircraft Manufacturing?

The maker of the Predator and SkyGuardian remote aircraft can implement additive manufacturing more rapidly and widely than the makers of other types of planes. The role of 3D printing in current and future UAS components hints at how far AM can go to save cost and time in aircraft production and design.