Materials

Mold Shop Evaluates Mantle Process for 3D Printing Steel Injection Molds

According to tests performed by Westminster Tool, Mantle’s 3D printing materials behave similarly to traditional steels and hold up well during molding, making them easy to incorporate into existing moldmaking processes.

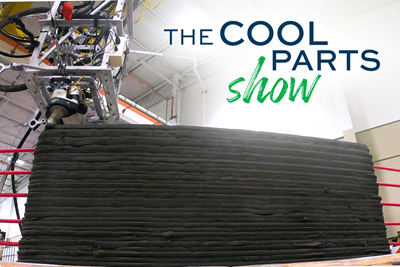

Read More3D Printed Concrete Is Key to This Smart Wall: The Cool Parts Show #40

The SkyBAAM cable-driven 3D printer creates opportunities for embedded functionality in concrete, as demonstrated in this episode of The Cool Parts Show.

WatchArkema, EOS Launch Carbon Neutral Bio-Circular Powder for Additive Manufacturing

The company says the sustainable Rilsan polyamide 11 powders, produced entirely from renewable castor beans, are recognized worldwide for superior properties and performance in terms of toughness, durability, light weight and processing versatility.

Read MoreVelo3D Qualifies New Superalloy for Use in Its Sapphire Printers

New nickel-based Höganäs Amperprint 0233 Haynes 282 powder enhances the capabilities of Velo3D’s end-to-end solution for customers in oil and gas, aviation, energy, space and other high-value applications.

Read MoreAddUp and WBA Collaborate on Additive Manufacturing for Toolmaking

As part of the partnership, a FormUp 350 New Generation powder bed system from AddUp will be installed at the WBA Demonstration Tool Shop.

Read MoreFormlabs Launches PreForm Software for Improved Packing Densities

The software is designed to improve packing density, resulting in less leftover powder with each 3D print and a lower cost per part.

Read More10 Ways Additive Manufacturing Reshapes a Production Facility (Forget What You Know About Factories)

Sintavia’s purpose-built facility for powder bed fusion of aircraft components illustrates fundamental ways the plant is different when 3D printing is the operation.

Read MoreReshoring, Tooling, Sustainability and More: Top 10 Stories of 2021: AM Radio Episode #9B

Reviewing our most-viewed stories of the year revealed some of the topics that have been top-of-mind for additive manufacturers. Read or listen to the countdown.

ListenEOS, Metalpine to Jointly Develop Sustainable Metal Powder for Industrial 3D Printing

The future development involves Metalpine’s atomization technology coupled with EOS’ material, process and system development competence.

Read More3D Printed Magnets: The Cool Parts Show #38

Is it possible to 3D print a magnet? In this episode of The Cool Parts Show, we learn how magnets have been printed successfully at Oak Ridge National Lab, and the implications this has for energy, material conservation and supply chains.

Watch