LPBF

Video: How Multimaterial Laser Powder Bed Fusion Works

Penn State University’s CIMP-3D is exploring applications of the Schaeffler Aerosint system for multimaterial 3D printing. During a recent visit, I got an introduction to this system.

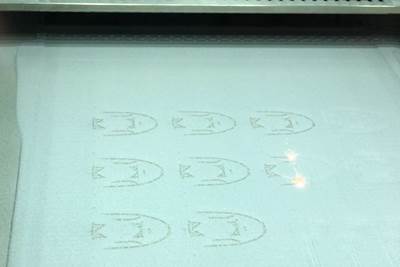

WatchFarsoon SRS Technology Reduces Number of Supports for Metal 3D Printing

The SRS (Support Reduction System) technology was developed to address one of the most challenging aspects of additive manufacturing — internal stress and deformation during the cooling phase of metal LPBF, which can lead to part failure, especially in overhanging structures.

Read MoreAddUp’s LevelUp Service Department Fosters Customers’ Industrial AM Capabilities

LevelUp endeavors to support customers through every stage of additive manufacturing, including training, application development, machine installation, qualification support and partnering with customers to scale, maximizing their return on investment.

Read MoreQuadrus: Powder Management Tactics for Tungsten Rhenium and Other AM Alloys

The expert in additive manufacturing of high-value parts for the Defense Department often must change from one exotic material to another in its powder bed machines. Cleaning is a core competency. Here are lessons of this company’s system for working with an ever-changing mix of 3D printed alloys.

Read MoreAmerica Makes Names Winners of Air Force Project Call Totaling $850,000

Awardees are tasked with identifying the current, emerging and future state of additive manufacturing (AM) process qualification, prioritizing AM machine qualification to quantitatively validate acceptable AM operations.

Read MoreAmerica Makes Announces Recipients of $2.9 Million Defense Project Call

The project award winners are tasked with demonstrating data gathering and analysis methods to drive industrywide metal additive manufacturing operations acceptance.

Read MoreXact Metal Works With Uddeholm as It Expands Into Tooling, Molding

Uddeholm’s Corrax for additive manufacturing is a corrosion-resistant, cobalt-free tool and mold steel capable of an A1 surface finish post-polishing.

Read MoreFarsoon FS721M CAMS Large Format Metal 3D Printer Offers Continuous Manufacturing Capability

The system features Farsoon’s continuous additive manufacturing solution (CAMS) multilaser platform, which includes eight lasers to enable true additive manufacturing series production with increased automation workflow.

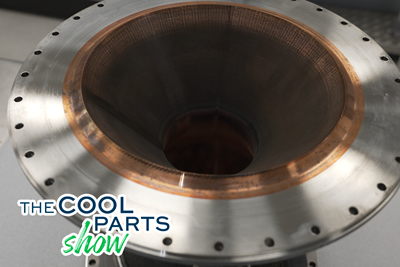

Read More3D Printed NASA Thrust Chamber Assembly Combines Two Metal Processes: The Cool Parts Show #71

Laser powder bed fusion and directed energy deposition combine for an integrated multimetal rocket propulsion system that will save cost and time for NASA. The Cool Parts Show visits NASA’s Marshall Space Flight Center.

WatchAdditive Manufacturing Versus Cavitation

The design freedom possible with laser powder bed fusion (LPBF) metal 3D printing is making it faster and easier to produce complex anticavitation devices for valves.

Watch