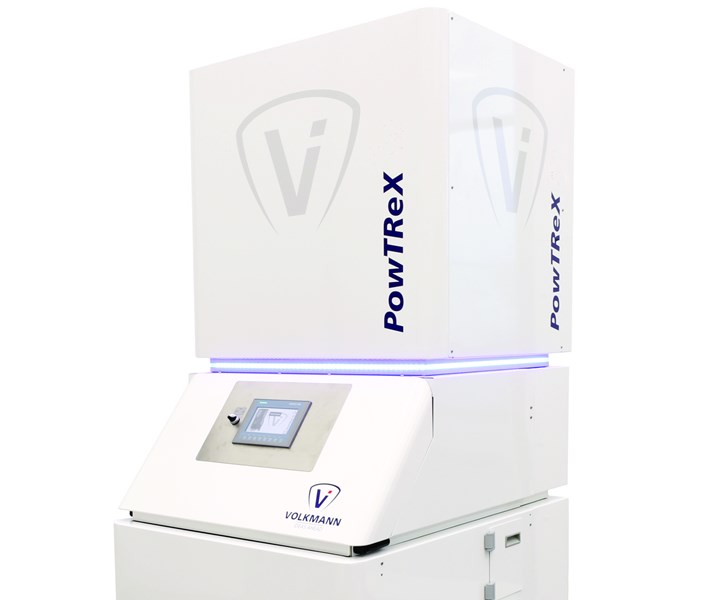

Volkmann PowTrex Eliminates Metal Powder Waste

RAPID 2020: Volkmann’s PowTrex recovery station provides contained metal powder transfer, recovery of unused material, screening for oversize agglomerates and return-to-use of the material.

Share

Read Next

Volkmann PowTrex systems not only eliminate needless waste of costly metal powders but also to avoid risks when handling these potentially explosive or toxic materials during additive manufacture, thereby keeping the manufacturing operation running at peak efficiency.

Volkmann’s PowTrex recovery station provides contained metal powder transfer, recovery of unused material, screening for oversize agglomerates and return-to-use of the material. The system transfers high bulk density powders with high throughput rates, capable of handling powdered metals such as stainless steel, aluminum alloys, titanium, chromium-nickel alloys, copper and others. PowTrex operates at throughputs of above 1100 lbs/hr. for stainless steel on a 63µ screen, and above 660 lbs/hr for aluminum powder.

Two options are available, inert or non-inert, (both with high levels of containment) to meet requirements due to potential environmental issues, operator safety, and oxidation level requirements. The inert PowTReXi system is designed in a closed loop configuration so inert gas is both contained and reused, avoiding the additional cost of large volumes of inert gas. It offers a high performance, fully inert process with two O2 sensors, an active container and system purging along with a special configuration gas-tight electric pump to maintain system temperature and containment.

Related Content

-

Beehive Industries Is Going Big on Small-Scale Engines Made Through Additive Manufacturing

Backed by decades of experience in both aviation and additive, the company is now laser-focused on a single goal: developing, proving and scaling production of engines providing 5,000 lbs of thrust or less.

-

AM 101: What Is Binder Jetting? (Includes Video)

Binder jetting requires no support structures, is accurate and repeatable, and is said to eliminate dimensional distortion problems common in some high-heat 3D technologies. Here is a look at how binder jetting works and its benefits for additive manufacturing.

-

3D Printing Molds With Metal Paste: The Mantle Process Explained (Video)

Metal paste is the starting point for a process using 3D printing, CNC shaping and sintering to deliver precise H13 or P20 steel tooling for plastics injection molding. Peter Zelinski talks through the steps of the process in this video filmed with Mantle equipment.