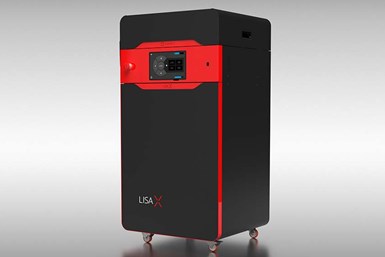

Sinterit Lisa X Designed for Faster, Larger SLS Print Volumes

The Lisa X is a third-generation compact SLS 3D printer, offering printing times 10 times faster than the Lisa PRO.

The Lisa X is said to offer both faster prints and bigger print volumes with no need for supports.

Sinterit is launching the Lisa X, a compact selective laser sintering (SLS) 3D printer designed to provide fast, agile production with a sintering speed that provides printing times 10 times faster than the company’s Lisa PRO.

The Lisa X is said to offer both faster prints and bigger print volumes with no need for supports. With a build speed of 10-14 mm/hr. for PA12 material, Lisa X is the the company’s fastest compact SLS 3D printer. The company says the full print bed can be printed in 30 hours, while most prints can be ready in less than 24 hours.

The printer is also said to provide next-day prototyping usability. With the high-speed Lisa X, users can get more printed elements per week and more tested designs, the company says. That means less time waiting for results and more time for improving designs, thereby accelerating time-to-market for new products and decreasing prototyping costs.

The build size is 130 × 170 × 330 mm (5.1" × 7.1" × 13.0"), enabling it to print larger prototypes. The bigger volume and faster printing time can also result in optimal printing costs. As more prints and tests can be done in just one run, less powder and energy is used. The company says materials are easy to change and cleaning the printer doesn’t force users to wait for the printer to be used. It is also said the powder refresh ratio means that users don’t have to add a lot of fresh powder to make new prints. Users can reuse the powder that wasn’t sintered during printing for both economical and ecological productivity.

Lisa X is also equipped with a special airblade that enables more efficient preparation for printing. Instead of cleaning laser glass each time before printing, the airblade cleans it automatically during printing which means users only needs to clean the laser glass after three print cycles, not after each one, the company says.

Related Content

-

Airless Basketball Shows Promise of 3D Printed Lattices: The Cool Parts Show Bonus

Successfully matching the performance of a standard basketball demonstrates the control possible over the mechanical properties of digital materials.

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Possibilities From Electroplating 3D Printed Plastic Parts

Adding layers of nickel or copper to 3D printed polymer can impart desired properties such as electrical conductivity, EMI shielding, abrasion resistance and improved strength — approaching and even exceeding 3D printed metal, according to RePliForm.