Siemens PLM Simulation Software Identifies 3D Printing Problem Areas

Rapid 2019: Siemens’ additive manufacturing (AM) process simulation product, part of its Simcenter 3D AM solution, is integrated into its NX CAD/CAM/CAE solution set.

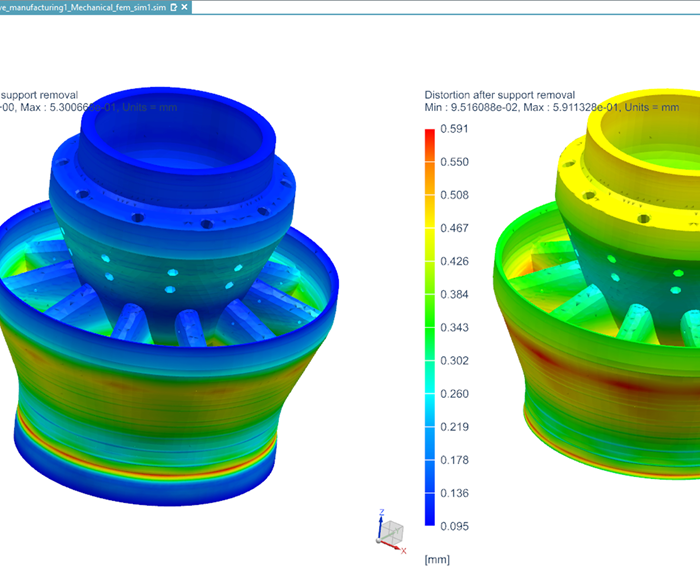

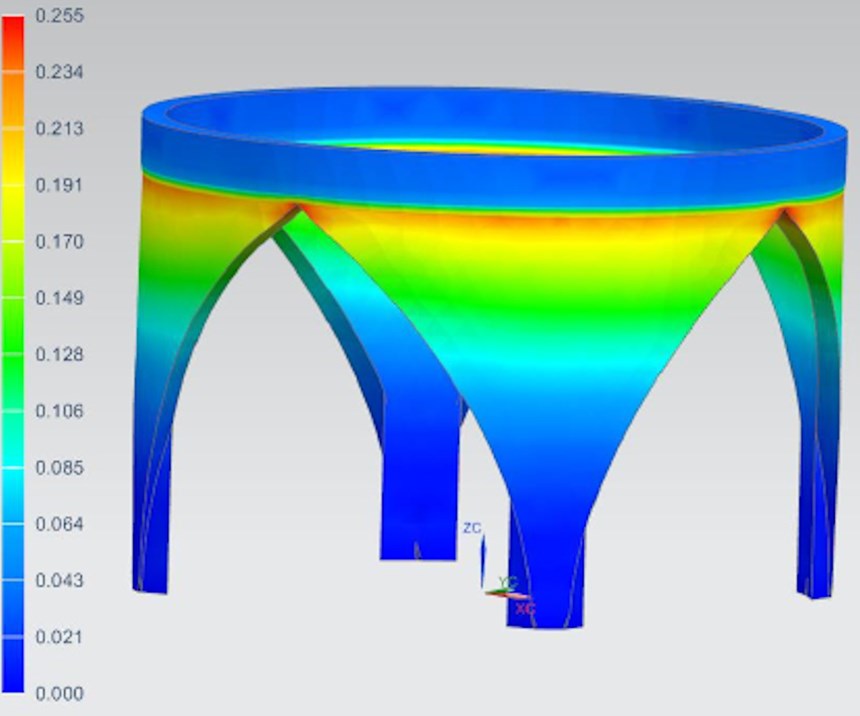

Siemens’ additive manufacturing (AM) process simulation product, part of its Simcenter 3D AM solution, is integrated into its NX CAD/CAM/CAE solution set. The tool enables users to simulate metal powder-bed deposition to achieve a first-time-right print, the company says. The simulation tool identifies regions of distortion, shrink lines, possible recoater collisions and areas of local overheating during material deposition.

Users can generate pre-compensated models to correct areas of distortion found during simulation. The product is said to be highly accurate and can save metal 3D printing companies time and money by eliminating the need for test prints.

Related Content

-

Overcoming the Bottleneck to Customized Manufacturing: Quoting

Spokbee’s software-as-a-service platform is shaving months off of the quoting and pricing process for 3D printed and other types of configurable products.

-

The Top 10 Additive Manufacturing Stories of 2024

Defense, space exploration, thermal management — these are some of the topics that captured the Additive Manufacturing audience’s interest in 2024. But there’s also an overarching theme: Don't wait for additive manufacturing to be perfect. Instead, leverage the applications perfect for AM.

-

Spherene Creates Metamaterial with Geometry Derived from Spheres

An algorithm developed by Spherene Inc. generates Adaptive Density Minimal Surfaces (ADMS) as a self-supporting infill strategy that can be used to reduce mass and manage material properties in 3D printed parts.