Shotless Cavitation Water Jet Peening Technology

IMTS 2022: Sugino’s shotless water jet peening is well suited for medical devices that need the benefits of shot peening without the contamination of traditional peening media.

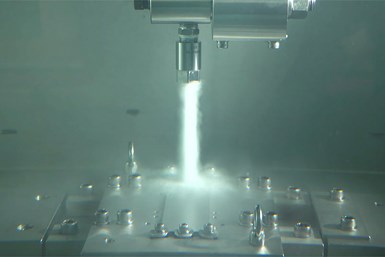

Sugino’s special cavitation promoting nozzle creates GPa class impact force Photo Credit: Sugino Corp.

Sugino’s cavitation water jet peening technology is a shotless peening process that uses only water. It is available with four-axis CNC control for targeted peening that doesn’t require masking and is said to deliver results without waste, safety hazards or extensive cleanup, the company says.

The company says its cavitation-promoting nozzle applies compressive stress to a depth of about 1 mm, achieved through the impact of GPa class force. The cavitation water jet peening is said to deliver increased fatigue strength, longer life and a cleaner finished product.

The process has delivered results on titanium alloy additive and 3D printed parts, specifically those using Ti-6AL-4V powder, the company says. It’s well suited for medical devices that need the benefits of shot peening without the contamination of traditional peening media. It is said this focused technology is able to peen inside holes, tubes and cavities, and uses only water, requiring no additional cleaning processes.

Related Content

-

3D Printed Spine Implants Made From PEEK Now in Production

Medical device manufacturer Curiteva is producing two families of spinal implants using a proprietary process for 3D printing porous polyether ether ketone (PEEK).

-

Overcoming Challenges with 3D Printing Nitinol (and Other Oxygen-Sensitive Alloys) Through Atmospheric Control

3D printed nitinol has potential applications in dental, medical and more but oxygen pickup can make this material challenging to process. Linde shares how atmospheric monitoring and the use of special gas mixtures can help maintain the correct atmosphere for printing this shape alloy and other metals.

-

8 Cool Parts From Formnext 2023: The Cool Parts Show #65

New additive manufacturing technologies on display at Formnext were in many cases producing notable end-use components. Here are some of the coolest parts we found at this year’s show.