SBI Unveils M3DP Metal AM System for Serial Production

SBI has announced its metallic 3D printing (M3DP) system, a wire and arc additive manufacturing (WAAM) process that uses a plasma arc and welding wire.

SBI has unveiled its Metallic 3D Printing (M3DP), a wire and arc additive manufacturing (WAAM) process that uses a plasma arc and welding wire. M3DP is said to be a high-performance additive manufacturing (AM) process in terms of order rate, volume and competitiveness.

A plasma torch guided by a CNC gantry system creates a local melt pool. Welding wire fed into the molten bath applies material to create components. Developed for metallic 3D printing of materials including aluminum, titanium, mild steel, stainless steel, nickel-base alloys and copper, M3DP is said to be well-suited for the production of large structural components.

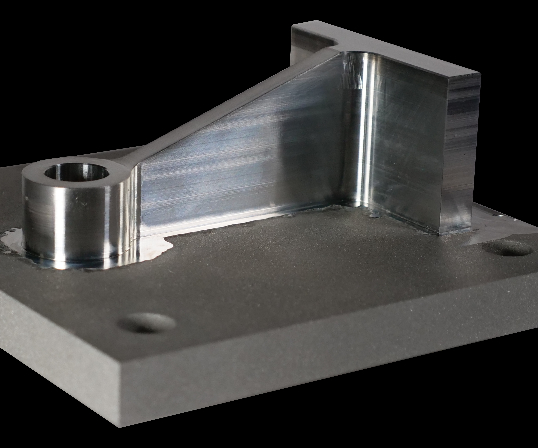

The M3DP offers a small footprint compared to its build volume. It also provides high deposition rates, ranging to 10 kg/hr. when using steel. Parts produced by WAAM are near-net shape but require machining after printing, a far lower degree than machining out of a solid substrate, saving cost.

According to the company, the advantage of metallic printing is the independent focused arc. Because it is separate from the feeded wire, the plasma arc can be used during the process for heating and printing applications.

Before starting to print, slicer software generates a readable G code file by slicing the 3D cad file into vertical layers and creating a print strategy. This strategy is further combined with parameters and routines and then the G code is transmitted to the printer, which executes the code and prints the part layer by layer.

The process is video logged, timestamped and linked to relevant parameters including the welding current, wire feed speed and traveling speed, enabling postprocess analysis and optimization, the company says. After each layer, a 3D scan guarantees that the printed shape fulfills the geometrical requirements. The 3D scan is matched with the 3D CAD file to check if the printed part fits the desired 3D model, and is used to create an adaptive control of the print process.

The standard product has several elements, including the build volume configurations and in situ quality options, which can be configured to the customer’s need, the company says. The M3DP can be optionally enclosed by a gas-tight cover for an inert gas atmosphere to process sensitive materials such as titanium and nickel-based alloys. Atmospheres with less than 15 ppm oxygen and 30 ppm moisture can be achieved.

The main field of applications for the M3DP are aerospace, tooling, oil and gas, naval architecture as well as mechanical engineering and automotive.

Related Content

-

Caracol Develops Vipra AM Robotic Metal DED 3D Printing Platform for Manufacturing Large-Scale Metal Parts

Formnext 2024: The integrated DED metal platform for large-scale components combines hardware and software with advanced robotic monitoring and automation.

-

Top 10 Additive Manufacturing Stories of 2023

Laser powder bed fusion, proprietary AM processes, machining and more made our list of top 10 articles and videos by pageviews this year.

-

Video: Machining and Directed Energy Deposition (DED) Aid One Another and Work Together

DED parts made by a machine tool provider illustrate various ways the strategic consideration of either metal 3D printing or machining helps the other process.