QuickCast Air Software Maximizes Material Removal From Casting Pattern Interiors

The software tool optimizes material removal for cleaner burnout and more efficient draining to reduce both material consumption and build times, enabling a material efficiency that has demonstrated cost competitiveness with traditional injection molded wax patterns.

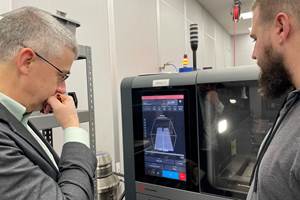

3D Systems’ SLA 750 Dual is a synchronous, dual-laser stereolithography printer which works with the QuickCast Air software tool to deliver large, high-precision investment casting patterns at a fraction of the time and cost of traditional tooling. Source: 3D Systems

3D Systems’ QuickCast Air is an advanced software tool designed to maximize material removal from the interior of casting patterns. This enables reduced material consumption, lower pattern costs, faster build times, cleaner burnout processes and improved draining efficiency. The company says this material efficiency has demonstrated cost competitiveness with traditional injection molded wax patterns

As a result, the company’s end-users in industries such as foundries, aerospace and defense, and energy can reliably deliver large, high-precision investment casting patterns at a fraction of the time and cost of traditional tooling and with no limitation on geometric complexity.

The company says QuickCast Air is already helping some of the company’s large-volume aerospace customers reduce the material consumption on their patterns by up to 50%, while customers are also seeing a multihour reduction in build times.

QuickCast Air is available to 3D Systems’ customers through its 3D Sprint software which is integral to the company’s polymer printing platforms. This feature, available via an annual subscription, enables customers to design casting patterns with fewer structures within the self-supporting walls. Using less resin and building more refined support structures results in less material needing to be burned out and thus less ash. Also, having less internal structure makes it easier to drain the resin, thus retaining more within the vat during the draining process rather than being lost downstream. Within 3D Sprint, users can easily adjust the part’s shell thickness and add vents and drains on any surface, simplifying part setup regardless of the build orientation.

Investment casting is the process of pouring molten metal into ceramic shells made from sacrificial patterns. According to the company, using traditional methods such as creating a wax injection tool is both time consuming and expensive, requiring several weeks and tens of thousands of dollars. In the mid-1990s, 3D Systems started creating high-precision casting patterns using 3D printing with QuickCast. This 3D printed investment casting process enables manufacturers to produce lightweight, hollow parts with 3D Systems’ polymer technologies such as stereolithography (SLA), or Multijet Printing (MJP) that ultimately can be used to produce end-use metal components. QuickCast patterns enable manufacturers to improve efficiency and reduce cost.

“Since 3D Systems introduced QuickCast more than two decades ago, we have continued to evolve this unique tool and the capabilities it provides,” says Patrick Dunne, 3D Systems ‘ vice president, advanced applications. “Our customer-centric approach to innovation fuels this transformation by closely aligning with their unique challenges. As with many of our products, QuickCast Air was born from a specific customer’s application requirements. I’m pleased that we are now able to bring this advanced tool to market thus refining the design and production of investment casting patterns. I’m looking forward to seeing how the adoption of QuickCast Air will continue to unlock design freedom and accelerate production timelines.”

The company says additive manufacturing (AM) is disrupting the investment casting sector by enabling a more cost-effective, efficient alternative to the traditional pattern-making process with a solution that does not require tooling. The 3D Systems’ solution — which includes materials, 3D printing technologies, software and services — has been helping customers address their application challenges to reliably deliver large, high-precision casting patterns in a fraction of the time and at much lower cost than those associated with traditional tooling.

Related Content

Seurat: Speed Is How AM Competes Against Machining, Casting, Forging

“We don’t ask for DFAM first,” says CEO. A new Boston-area additive manufacturing factory will deliver high-volume metal part production at unit costs beating conventional processes.

Read MorePostprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreFreeform: Binder Jetting Does Not Change the Basics of Manufacturing

Rather than adapting production methodologies to additive manufacturing, this Pennsylvania contract manufacturer adapts AM to production methodologies. In general, this starts with conversation.

Read MoreAdditive Manufacturing Is Subtractive, Too: How CNC Machining Integrates With AM (Includes Video)

For Keselowski Advanced Manufacturing, succeeding with laser powder bed fusion as a production process means developing a machine shop that is responsive to, and moves at the pacing of, metal 3D printing.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More