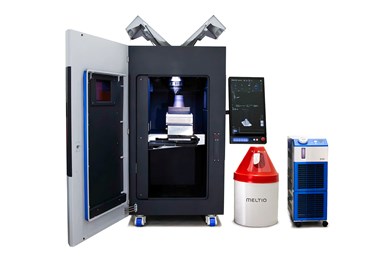

Meltio M600 Wire-Laser System Reduces Material Waste, Lead Times While Increasing Manufacturing Flexibility

The Meltio M600 can seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces.

Meltio says its M600 metal 3D printer expands manufacturing capabilities with its blue lasers, large build volume and fully inert chamber for the best material properties. The printer is designed to solve the problems of long lead times, costly stock-keeping and fragile supply chains.

This wire-laser metal directed energy deposition (DED) system was conceived to introduce metal additive manufacturing (AM) to the world of industrial production outside of niche areas. The system increases productivity and reduces manufacturing costs, utilizes new materials and is ready to perform 24/7 with minimal operator interaction for autonomous production.

The combination of wire deposition, blue lasers, a large fully inert workspace (300 × 400 × 600 mm - X, Y, Z) and smart sensors enable the Meltio M600 to process the most demanding materials — from titanium to copper and aluminium alloys, and many more including stainless steels, tool steels, nickel, invar and Inconel.

The system can also seamlessly integrate into machine shops and production environments, enabling not only the printing of entire metal parts but also the addition of features to existing components and the repair of damaged surfaces. This is facilitated by the built-in 3-axis touch probe and support for various workholding solutions, including zero-point clamping.

“The design brief for the new Meltio M600 was to imagine what the perfect 3D printer for the machine shop would look like,” says Lukas Hoppe, Meltio research and development director. “The vast majority of metal 3D printed parts require postprocessing, which is carried out in the machine shop and since our ambition is to push the large-scale adoption of metal additive manufacturing, we have a very clear vision that the modern machine shop is the ideal point of entry.”

Meltio says that manufacturing faces many challenges globally — from long lead times and stock-keeping costs caused by long and fragile supply chains to an ever-growing pressure to lower costs and reduce emissions.

“3D Printing has huge potential to address these issues as it helps reduce lead times and manufacturing dependencies by printing parts in-house, reduces warehouse inventory as the raw material can be transformed into the final part on demand and reduces costs by applying material only where it is needed,” Hoppe says. “It has, however, yet to realize this potential. In fact, we still see metal AM mostly applied to very high-value applications, and this is where the Meltio M600 comes in as it improves on the state-of-the-art in a few very significant ways.”

The system uses welding wire as its feedstock, compared to the more common powder-based 3D printer. Having a wire material that is cheaper, safe to handle and does not risk contamination of users’ CNC machines can be an advantage for industrial integration, the company says. Printing parts with the wire-laser deposition process also produces high-quality components with material properties that are comparable to conventionally manufactured parts.

The company’s blue laser deposition head increases printing speed while reducing energy consumption because of the increased absorption of the short wavelength light — compared to most industrial lasers which emit near-infrared light. This advantage is multiplied for reflective materials such as copper and aluminum alloys where near-infrared lasers lead to unsatisfactory results. Combining this with the fully inert workspace, the Meltio M600 can process a large range of materials efficiently while producing parts with exceptional properties, Hoppe says.

The complete system has been designed to easily interface in the same industrial environment with CNC machines. It features a built-in 3-axis touch probe and supports various types of workholding solutions, which means users can also add features to or repair existing parts rather than printing them entirely.

The Meltio M600 is also highly autonomous meaning that operator interaction is minimal. Common touch points such as manual laser alignment have been removed for increased reliability, and programming is a matter of minutes because of the Meltio Horizon, which is the dedicated slicer for the Meltio M600.

To make this tool for machine shop use a reality, the company says the Meltio M600 is the first Industrial wire-laser metal 3D printer that incorporates a blue laser deposition head. These lasers improve energy absorption and printing efficiency across the metal spectrum and open up new material possibilities while reducing the carbon footprint for production.

The Meltio engineers have also managed to improve the energy distribution and wire guidance such that the deposition head is aligned from the factory and not operator-adjustable, thereby leading to consistent output and reduced maintenance. Also, the head is laden with new and improved sensor solutions for monitoring the printing process, which makes printing more reliable.

While the Meltio M600 is interesting to a broad range of sectors, the company’s goal was to design a system that fits right into any machine shop and works alongside CNC machines, creating value by reducing material waste and lead times, enabling increased manufacturing flexibility. To realize this vision Meltio’s focus was a system that works like a machine tool, designed for lights-out manufacturing, and is easy to use, enabling existing operators to complete complex print jobs with minimal time investment.

Related Content

Video: Machining and Directed Energy Deposition (DED) Aid One Another and Work Together

DED parts made by a machine tool provider illustrate various ways the strategic consideration of either metal 3D printing or machining helps the other process.

Read More3D Printed Titanium Replaces Aluminum for Unmanned Aircraft Wing Splice: The Cool Parts Show #72

Rapid Plasma Deposition produces the near-net-shape preform for a newly designed wing splice for remotely piloted aircraft from General Atomics. The Cool Parts Show visits Norsk Titanium, where this part is made.

Read MoreVideo: 5" Diameter Navy Artillery Rounds Made Through Robot Directed Energy Deposition (DED) Instead of Forging

Big Metal Additive conceives additive manufacturing production factory making hundreds of Navy projectile housings per day.

Read MoreBig Metal Additive: The Difference Between a Shape and a Part Is Quality

Preparing to scale directed energy deposition to ongoing full production is not a technological challenge: DED is ready. But it is an organizational challenge, says the company founder. Here is what it means to implement a quality system.

Read MoreRead Next

Postprocessing Steps and Costs for Metal 3D Printing

When your metal part is done 3D printing, you just pull it out of the machine and start using it, right? Not exactly.

Read MoreCrushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreProfilometry-Based Indentation Plastometry (PIP) as an Alternative to Standard Tensile Testing

UK-based Plastometrex offers a benchtop testing device utilizing PIP to quickly and easily analyze the yield strength, tensile strength and uniform elongation of samples and even printed parts. The solution is particularly useful for additive manufacturing.

Read More