Materialise Expands CO-AM Platform With 7 Technology Partners, Magics Integration

With the addition of the seven new partners, Materialise says it delivers on the promise to connect and automate all steps of the AM process, including automating design, labeling, machine monitoring and postprocessing.

Materialise, a global provider of 3D printing software and service solutions, has added seven additional technology partners to its CO-AM platform. These solutions support design and preprinting automation, traceability, printing and postprocessing for 3D printed parts. Also, Materialise Magics has been integrated to CO-AM and offers a new workflow automation feature.

The additions are said to address the need for an open ecosystem. “With these new partnerships, the CO-AM community continues to grow, creating the first end-to-end software platform that offers an open ecosystem for the additive manufacturing (AM) industry,” says Bart van der Schueren, Materialise CTO. “Collaboration is key to realize the potential of additive manufacturing and to give our customers seamless access to a full range of software tools to plan, manage and optimize every step of their 3D printing process.”

Since launching the CO-AM Platform in May 2022, more than ten companies have joined as technology partners. New partners include: Trinckle which adds design automation for jigs and fixtures; Twikit offers a mass customization solution including design automation and automated order creation; Additive Marking enables digital traceability through automated labeling and authentication technology; Printer Connectivity with SLM Solutions’ 3D printers help monitor and document machine data; and solutions from AMT, DyeMansion, and PostProcess automate and track postprocessing steps.

The Materialise CO-AM platform offers a space for innovation and co-development to the AM industry and manufacturing companies. It presents an open software architecture that provides manufacturing companies direct access to multiple hardware technologies and their preferred tools from Materialise and other software developers. This will enable the CO-AM community to co-develop end-to-end manufacturing solutions that create competitive advantages for individual companies and empower entire industries.

Customers in major manufacturing industries — including aerospace, automotive, consumer, medical and energy — will have access to the latest AM innovations via the platform and will be able to integrate and connect them seamlessly.

The aim is to connect and automate all parts of the AM factory. “End-to-end connectivity in CO-AM offers significant advantages for our partners and our customers,” says Vishal Singh, senior director of CO-AM. “For our partners, connecting their applications to the CO-AM platform provides them with opportunities to reach new customers more efficiently. Our customers benefit from a unified user experience throughout Materialise and partner solutions.”

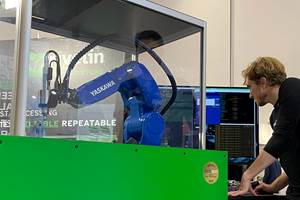

It is said manufacturing companies turn to AM to mass produce identical or customized products. However, they are looking for ways to achieve repeatable quality standards and minimize the amount of manual intervention. With the addition of the seven new partners, Materialise delivers on the promise to connect and automate all steps of the AM process.

The new solutions automate design, labeling, machine monitoring and postprocessing. The CO-AM platform gives users the flexibility to build a process that is tailored to their business. A growing number of tools to support each step in the AM workflow enables them to choose their preferred solution.

Materialise has also extended the integration of Magics 26, its flagship data and build preparation software, into CO-AM. The integration enhances traceability, enabling users to monitor and improve AM processes throughout the workflow, from data preparation through design iterations to the final printed part.

In addition, Magics’ new workflow automation feature offers off-the-shelf scripts to automate common build preparation workflows and enable customers to use customizable scripts to automate build preparation tasks unique to their AM operations.

“The deep integration and workflow automation feature of Magics in CO-AM creates a digital thread between data and build preparation and the overall AM workflow,” says Egwin Bovyn, product line manager of Magics 3D Print Suite at Materialise. “This is an important step to enable data management across all technologies within CO-AM. It will allow users to reduce production costs and scale AM operations more efficiently.”

- Learn more about Materialise’s CO-AM open platform which is said to give manufacturers cloud-based access to a full range of software tools that enable them to plan, manage and optimize every stage of their additive manufacturing operations.

Related Content

The Robot Craftsman: Force Sensing and Vision Help Realize Automated AM Postprocessing (Includes Video)

Automated production via additive manufacturing will need automated postprocessing. This UK startup is equipping robots with the capabilities needed for critical, fine-detail finishing of metal 3D printed parts.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read MoreFormlabs Part Removal Mechanism Enables Lights-Out Production

A build platform overcoming the need for manual part removal enables automated part handling, and therefore continuous production from one build cycle to the next.

Read MoreSavage Automation Delivers 3D Printed Commercial Manufacturing Aids

The company's approach to designing end-of-arm tooling and other devices has evolved over the years to support longevity and repairs.

Read MoreRead Next

Crushable Lattices: The Lightweight Structures That Will Protect an Interplanetary Payload

NASA uses laser powder bed fusion plus chemical etching to create the lattice forms engineered to keep Mars rocks safe during a crash landing on Earth.

Read MoreAlquist 3D Looks Toward a Carbon-Sequestering Future with 3D Printed Infrastructure

The Colorado startup aims to reduce the carbon footprint of new buildings, homes and city infrastructure with robotic 3D printing and a specialized geopolymer material.

Read More3D Printed Polymer EOAT Increases Safety of Cobots

Contract manufacturer Anubis 3D applies polymer 3D printing processes to manufacture cobot tooling that is lightweight, smooth and safer for human interaction.

Read More